HP5V Series Axial Piston Variable Displacement Hydraulic Pump

HP5V Series Axial Piston Variable Displacement Hydraulic Pump

The HP5V series axial piston variable displacement hydraulic pump is a cutting-edge hydraulic component that offers unmatched efficiency and performance in various industrial applications. Designed with precision engineering and advanced technology, this pump delivers reliable and precise hydraulic power, making it an essential choice for demanding hydraulic systems. This comprehensive article will delve into the key characteristics, usage methods, and maintenance guidelines for the HP5V series axial piston variable displacement hydraulic pump.

The HP5V series axial piston variable displacement hydraulic pump is a high-performance and efficient solution for hydraulic systems. With its variable displacement technology, compact design, and quiet operation, this pump delivers reliable and precise hydraulic power. By following the recommended usage methods and adhering to regular maintenance practices, the HP5V series pump will continue to provide exceptional performance, contributing to the success of a wide range of industrial applications. Embrace the efficiency and performance of the hp5v series axial piston variable displacement hydraulic pump and unlock the full potential of your hydraulic system.

HP5V Series Axial Piston Variable Displacement Hydraulic Pump Key Characteristics:

- Variable Displacement Technology: The HP5V series pump features variable displacement technology, allowing it to adjust its output volume based on system requirements. This capability maximizes energy efficiency, reduces heat generation, and optimizes overall system performance.

- High Efficiency and Performance: The HP5V series pump delivers exceptional efficiency and performance with its advanced axial piston design. It provides precise and reliable hydraulic power, ensuring smooth operation and easy handling of high-pressure applications.

- Compact and Space-Saving Design: The pump’s compact design optimizes space utilization within hydraulic systems. Its small footprint allows easy integration, even in tight spaces, while maintaining excellent performance and functionality.

- Quiet Operation: The HP5V series pump is engineered with noise reduction features, ensuring quiet operation in diverse industrial environments. This characteristic is precious in applications that require low noise levels, promoting a comfortable and productive work environment.

HP5V Series Axial Piston Variable Displacement Hydraulic Pump Parameter:

| Size | HP5VS28 | HP5V28 | HP5V45 | HP5V60 | HP5V76 | HP5V85 | HP5V105 | |

| Displacement (cc/rev) | 28 | 28 | 45 | 60 | 76 | 85 | 104.3 | |

| Pressure | Rated pressure(bar) | 250 | 320 | 320 | 250 | 320 | 280 | 350 |

| Peak pressure(bar) | 315 | 350 | 350 | 280 | 350 | 320 | 400 | |

| Rotation speed r/min | Max for self-priming *1 (bar) | 3000 | 3000 | 2700 | 2400 | 2400 | 2400 | 2200 |

| Max*2 (bar) | 3600 | 3600 | 3250 | 3000 | 3000 | 3000 | 2600 | |

| Weight (Kg) | 17.2 | 20 | 24 | 24 | 28 | 28 | 45 | |

| Quantity of oil to fill pump case (L) | 0.55 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 1 | |

| Temperature Range(℃) | -20~95 | |||||||

| Temperature Range(mm2/s) | 10-1000*3(The best use of viscosity range 16~36 mm2/s) | |||||||

HP5V Series Axial Piston Variable Displacement Hydraulic Pump Advantages:

• Variable pump in swash-plate design for open circuit.

• Compared with products in the existing market, reinforced drive shaft, high-strength cylinder material are utilized leading to the performance of continuous pressure of more than 320 bar.

• Heavy-duty bearings such as cylindrical rollers are adopted to enhance load carrying capacity and long service life.

• High power to weight ratio.

• Available with American (SAE) and Japanese (JIS) mounting flanges and shafts.

• Excellent reliability and long life.

• Variety of control options.

• Optional through drive.

• Quick control response.

• Low pressure pulsation and low noise.

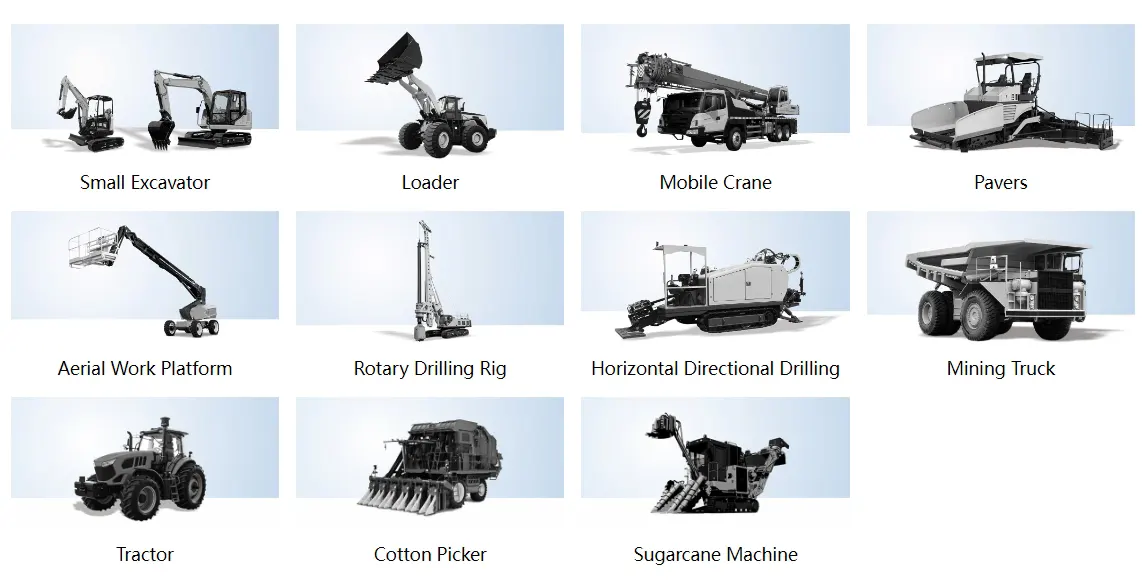

• Developed for engineering, mobile vehicles,industrial, other industrial application and agricultural machinery.

HP5V Series Axial Piston Variable Displacement Hydraulic Pump Application:

使用方法 HP5V Series Axial Piston Variable Displacement Hydraulic Pump:

- Pump Installation: Install the HP5V series axial piston variable displacement hydraulic pump in the designated location within the hydraulic system. Refer to the manufacturer’s guidelines and specifications for proper alignment and secure attachment to the system’s structure using suitable mounting brackets or accessories.

- 液压系统集成: Connect the pump to the hydraulic system using compatible hoses, fittings, and valves. Ensure all connections are secure, leak-free, and correctly tightened to guarantee optimal hydraulic performance.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the HP5V series pump. Refer to the manufacturer’s recommendations for the appropriate fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure proper pump operation and longevity.

- Operational Parameters: Familiarize yourself with the pump’s control options and adjust the operational parameters according to the specific requirements of the hydraulic system. Monitor and adjust the pump’s displacement settings to optimize performance and energy efficiency.

How To Change Seal On Hydraulic Cylinder?

Changing a seal on a hydraulic cylinder requires careful attention to detail and following proper procedures. Here’s a step-by-step guide to help you through the process:

- Preparation and Safety:

- Ensure the hydraulic cylinder is depressurized and disconnected from the system.

- Clean the exterior of the cylinder to prevent dirt or debris from entering during the process.

- Place the cylinder on a stable work surface and secure it using clamps or a vise.

- Identify the Seal:

- Determine the type of seal that needs replacement (e.g., rod seal, piston seal, wiper seal).

- Consult the cylinder’s technical documentation or contact the manufacturer to obtain the correct seal specifications.

- Disassembly:

- Remove any retaining components such as bolts, snap rings, or retaining rings that secure the cylinder head or cap.

- Carefully remove the cylinder head or cap, exposing the piston, rod, and the old seal.

- Remove the Old Seal:

- Use an appropriate tool like a seal pick, hook, or small screwdriver to pry out the old seal gently.

- Take care not to damage the cylinder surfaces during this process.

- Inspect the cylinder bore and rod for any signs of damage or wear. Consider a professional inspection or replacing the entire cylinder if significant damage is present.

- Clean and Lubricate:

- Thoroughly clean the cylinder bore, rod, and surrounding components using a lint-free cloth or a suitable solvent.

- Apply a thin layer of hydraulic oil or seal lubricant to the new seal to aid in installation and ensure proper sealing.

- Install the New Seal:

- Carefully position the new seal in its groove, ensuring it is correctly oriented.

- Use a seal installation tool or a soft mallet to gently press the seal into place, applying even pressure around its circumference.

- Ensure the seal is seated properly and fully inserted into the groove.

- Reassembly:

- Reinstall any remaining components removed during disassembly, such as bolts, snap rings, or retaining rings.

- Follow the manufacturer’s torque values and tightening sequence specifications to ensure proper sealing and alignment.

- Testing and Inspection:

- Reconnect the hydraulic cylinder to the system and ensure all connections are secure.

- Gradually restore system pressure and check for any leaks or abnormal behavior.

- Cycle the hydraulic cylinder through its full range of motion to verify proper seal operation.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: