Replacement Of AHC19765 Hydraulic Cylinder

Replacement Of AHC19765 Hydraulic Cylinder

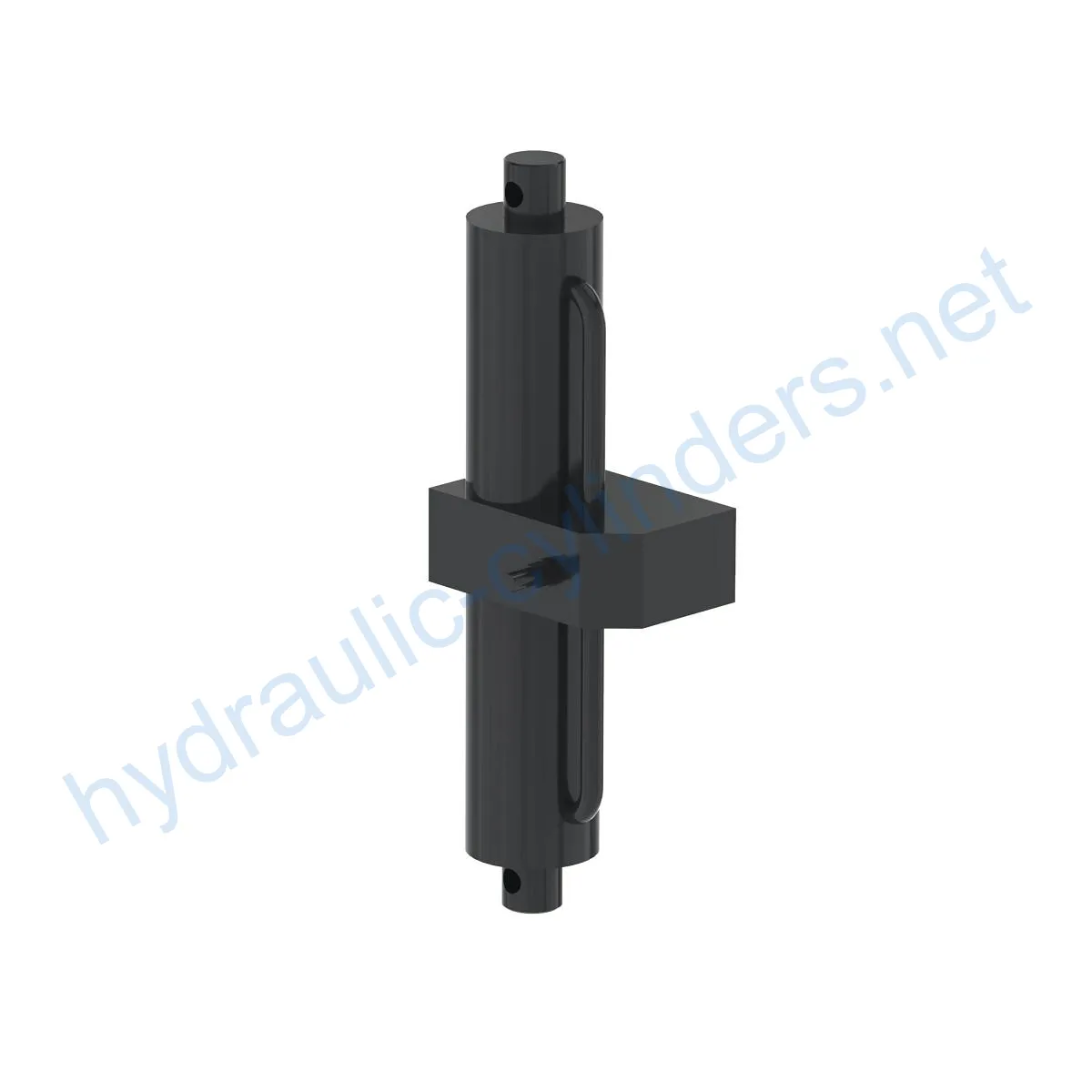

The Replacement Of AHC19765 Hydraulic Cylinder is a crucial component used in various equipment models including 444 P, 444L, 524 P, 524L, 544 P, 544L, 624 P, 624L, 644 P, 644 X, 644L, 644LH, 724 P, and 724L. This hydraulic cylinder weighs 18.94 lb and has dimensions of 4.4 in (height), 6.3 in (width), and 16 in (length).

Product Overview

The Replacement Of AHC19765 Hydraulic Cylinder is an essential part that plays a vital role in machinery operations. It functions to provide hydraulic force for various applications, ensuring the smooth and efficient movement of equipment.

Specifications and Models

The Replacement Of AHC19765 Hydraulic Cylinder has the following specifications and models:

- Weight: 18.94 lb

- Height: 4.4 in

- Width: 6.3 in

- Length: 16 in

Supported Equipment Models:

- 444 P

- 444L

- 524 P

- 524L

- 544 P

- 544L

- 624 P

- 624L

- 644 P

- 644 X

- 644L

- 644LH

- 724 P

- 724L

Product Features

- Enhanced Equipment Performance: Replacing damaged or worn hydraulic cylinders restores the equipment’s normal operational capabilities, ensuring optimum performance in various applications.

- Increased Safety: Regularly replacing hydraulic cylinders reduces safety hazards caused by cylinder failures, ensuring the safety of both operators and equipment.

- Overload Protection: New cylinder designs often incorporate improved overload protection mechanisms, enhancing overall safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized, making it easier to obtain replacement parts in the market.

Our company specializes in the production of replacement hydraulic cylinders, offering perfect alternatives to the mentioned models. We provide high-quality products that meet industry standards and surpass customer expectations.

Application Scenarios

The Replacement Of AHC19765 Hydraulic Cylinder finds extensive application in various industries. Here are three examples:

- Excavators: In excavators, hydraulic cylinders in the boom or bucket may become damaged due to long-term use or overload. Replacement is necessary to restore normal operation.

- Cranes: Hydraulic cylinders in crane jibs are prone to wear and tear during frequent lifting and lowering processes. Regular replacement ensures safety.

- Tractors: Front-end loader hydraulic cylinders in tractors may experience leaks or performance decline during continuous lifting and tilting operations. Replacement is required.

These are just a few examples, but the Replacement Of AHC19765 Hydraulic Cylinder is also utilized in harvesting machines, automated production lines, mining equipment, bulldozers, and more.

Maintenance Tasks

Regular maintenance is essential to prolong the lifespan of hydraulic cylinders. Here are three common maintenance tasks:

- Regular Inspections: Conduct periodic inspections to identify any signs of wear, leaks, or damage in the hydraulic cylinder. Prompt action can prevent further issues.

- Proper Lubrication: Apply the appropriate amount of hydraulic oil to ensure smooth operation and prevent excessive friction and wear.

- Seal Replacement and Calibration Checks: Replace worn seals and perform calibration checks to maintain the cylinder’s efficiency and prevent oil leakage.

During installation, it is crucial to provide guidance on aligning the cylinder correctly and suggest using suitable installation brackets for secure fixation. We recommend following recommended inspection, repair, and replacement procedures, as well as utilizing our replacement parts and rebuilding services to maximize the lifespan of the hydraulic cylinder.

Safety Considerations and Environmental Factors

When working with hydraulic cylinders, implementing safety measures is of utmost importance. Proper usage of safety equipment, adherence to operational guidelines, and regular training contribute to a safe working environment. Environmental factors should also be considered, such as proper disposal of used hydraulic oil and adherence to environmental regulations.

Fault Diagnosis and Common Issues

Detecting faults and addressing common issues in hydraulic cylinders is crucial for equipment performance. Here are some common problems:

- Oil Leakage: Oil leakage may indicate seal damage or improper cylinder alignment.

- Slow Operation: Slow cylinder movement can be a result of insufficient lubrication or internal component wear.

- Overheating: Overheating can be caused by excessive friction, inadequate lubrication, or system malfunctions.

To address these issues, it is essential to inspect and diagnose the problem accurately. Promptly resolve faults by following troubleshooting tips and solutions, providing preventative measures, and minimizing potential problems. Regular maintenance and adherence to recommended practices can prevent many hydraulic cylinder issues.

Product Design Considerations and Selection Standards

The design of hydraulic cylinders must take various factors into consideration:

- Load-Bearing Capacity: Hydraulic cylinders should be designed to withstand the intended load and provide efficient force transmission.

- Sealing: Proper sealing mechanisms, such as piston seals and rod seals made of durable materials like polyurethane and nitrile rubber, ensure effective fluid retention and minimize leakage.

- Durability: Cylinder bodies and threaded ends undergo fine treatment to enhance wear resistance and prolong cylinder life.

- Safety: Hydraulic cylinders are designed with safety features to prevent catastrophic failures and ensure operator protection.

- Maintainability: Easy access to internal components and an optimized design facilitate maintenance, repair, and replacement procedures.

Sealing and Lubrication

The Replacement Of AHC19765 Hydraulic Cylinder utilizes various sealing components, including piston seals and rod seals, which are made of wear-resistant materials like polyurethane and nitrile rubber. The cylinder body and threaded ends undergo precise surface

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: