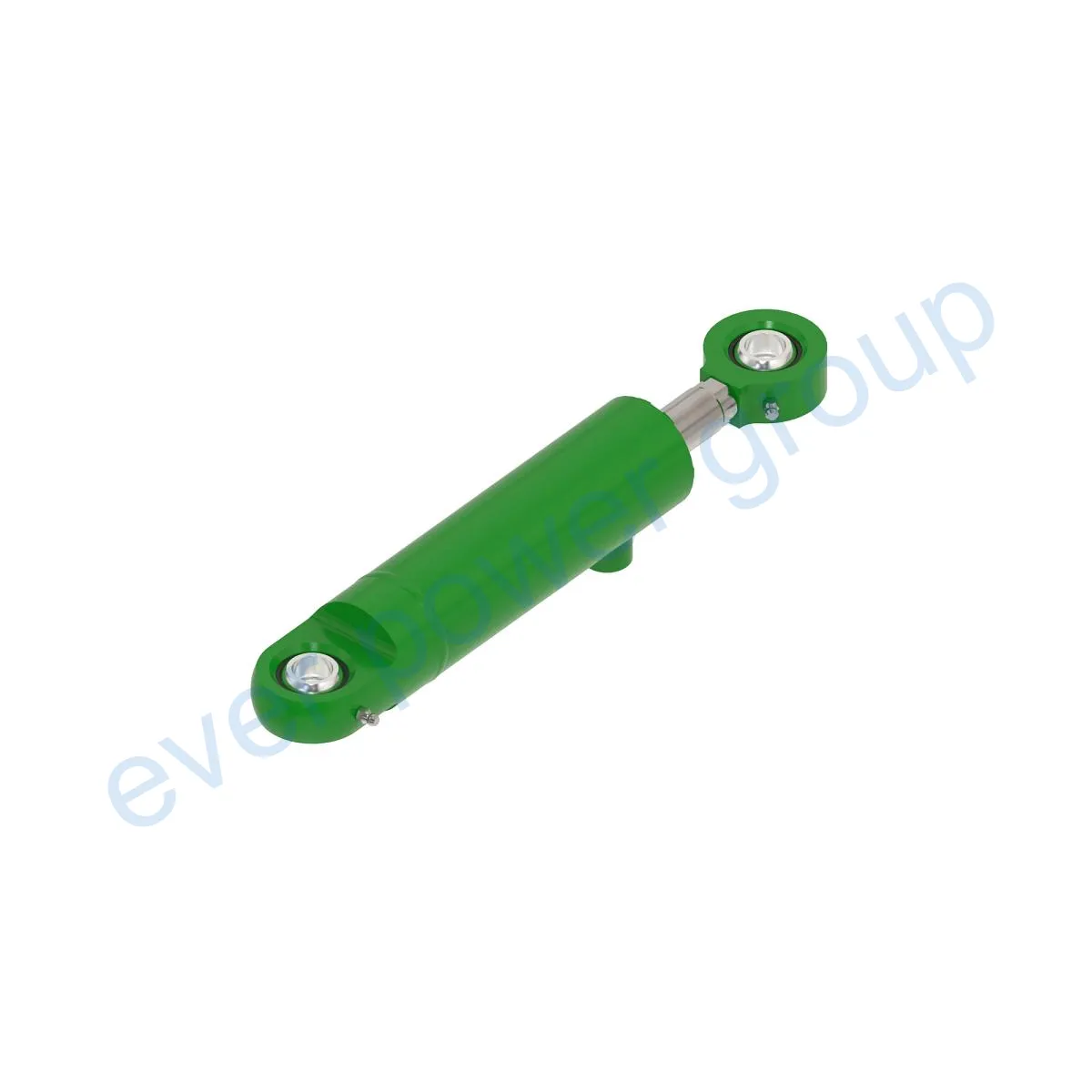

Replacement Of AXE85104 Hydraulic Cylinder

Replacement of AXE85104 Hydraulic Cylinder

The Replacement of AXE85104 Hydraulic Cylinder is a hydraulic cylinder that is used in various applications such as construction equipment, manufacturing, transportation, and aviation. It weighs 9.791 lb and has a height of 4.9 in, a width of 5.1 in, and a length of 16.2 in. This hydraulic cylinder can be used as a substitute for other hydraulic cylinders with the same specifications.

Product Specifications and Models

The Replacement of AXE85104 Hydraulic Cylinder has a weight of 9.791 lb, a height of 4.9 in, a width of 5.1 in, and a length of 16.2 in. It can be used in various machines and equipment.

Product Features

- High precision

- Excellent durability

- Superior sealability

- Easy to install

- Cost-effective

Our hydraulic cylinders can perfectly replace other hydraulic cylinders used in various applications such as construction equipment, manufacturing, transportation, and aviation.

Applications

Construction Equipment

The Replacement of AXE85104 Hydraulic Cylinder can be used in various construction equipment such as cranes, hoists, and elevators, where it is necessary to securely fix heavy objects.

Manufacturing

It can be used in high-pressure machines where materials are formed under high pressure, and the cylinder needs to be fixed during the processing.

Transportation

The hydraulic cylinder is used in stabilizers and jacks of vehicles, ensuring safety during maintenance or transportation.

Aviation

The hydraulic cylinder can be used in landing gear systems, where it securely fixes the landing gear in the appropriate position during takeoff and landing.

Design Considerations and Selection Criteria

Load-bearing capacity

The hydraulic cylinder should have a load-bearing capacity that meets the requirements of the application. It should be designed to withstand the load without bending or breaking.

Sealability

The hydraulic cylinder should have superior sealability to prevent oil leakage and reduce maintenance requirements.

Durability

The hydraulic cylinder should be durable and able to withstand wear and tear from regular use.

Safety

The hydraulic cylinder should be designed with safety in mind, with features such as safety valves to prevent accidents.

Maintainability

The hydraulic cylinder should be easy to maintain and repair, with replaceable parts readily available.

Sealing and Lubrication

The Replacement of AXE85104 Hydraulic Cylinder uses various sealing components such as piston sealing rings and rod sealing rings made of wear-resistant materials such as polyurethane and nitrile rubber. The cylinder body and thread end surface are finely processed to improve wear resistance. It requires regular addition of suitable hydraulic oil for lubrication.

Preventive Maintenance Measures

- Regular inspection of the hydraulic cylinder to detect signs of wear and tear.

- Proper lubrication to reduce friction and wear.

- Regular replacement of sealing components to prevent oil leakage.

Proper installation, lubrication, and adjustment are essential to ensure the longevity of the hydraulic cylinder. Proper alignment of the cylinder should be guided during installation, and appropriate installation brackets should be used to fix the cylinder. We recommend using our inspection, repair, and replacement services to ensure the longest possible service life of the hydraulic cylinder.

Product Installation Guide

1. Ensure that the installation area is clean and free of debris.

2. Align the hydraulic cylinder with the installation area and secure it using appropriate installation brackets.

3. Connect the hydraulic lines according to the manufacturer’s instructions.

4. Fill the hydraulic system with the appropriate hydraulic oil.

5. Test the hydraulic system for proper operation.

Maintenance Tasks

- Regular inspection

- Proper lubrication

- Seal replacement

Proper installation, lubrication, and adjustment are essential to ensure the longevity of the hydraulic cylinder. Proper alignment of the cylinder should be guided during installation, and appropriate installation brackets should be used to fix the cylinder. We recommend using our inspection, repair, and replacement services to ensure the longest possible service life of the hydraulic cylinder.

Safety Considerations and Environmental Factors

Safety is of utmost importance when using hydraulic cylinders. Proper safety measures should be taken, and all personnel should be trained on the proper use and maintenance of hydraulic cylinders. Environmental factors such as temperature and humidity should also be considered when using hydraulic cylinders.

Troubleshooting and Common Problems

Some common problems that may occur when using hydraulic cylinders include oil leakage, inadequate load-bearing capacity, and malfunctioning safety valves. Proper maintenance and repair can help prevent these issues. If problems do occur, our troubleshooting tips and solutions can help diagnose and solve the problem.

Author: lyl

About Our Company

We are a leading manufacturer and wholesale distributor of hydraulic cylinders for various applications such as construction equipment, manufacturing, transportation, and aviation. Our products are renowned for their high precision, excellent durability, superior sealability, and cost-effectiveness. We provide customized services and have achieved international certifications. Our production equipment is modern and efficient, and our after-sales service is top-notch.

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: