V80M Series Axial Piston Variable Displacement Hydraulic Pump

V80M Series Axial Piston Variable Displacement Hydraulic Pump

The V80M series axial piston variable displacement hydraulic pump is a cutting-edge solution designed to revolutionize the performance and efficiency of hydraulic systems. With its advanced features, precise control, and robust construction, this hydraulic pump sets a new standard in the industry.

The V80M series axial piston variable displacement hydraulic pump is a game-changer in hydraulic systems. Its variable displacement capability, high performance, and versatile design offer precise control, enhanced efficiency, and exceptional power delivery. By following the recommended usage methods and adhering to regular maintenance practices, the V80M series pump will continue to deliver outstanding performance, efficiency, and reliability. Embrace the power and efficiency of the v80m series axial piston variable displacement hydraulic pump to unlock the full potential of your hydraulic system.

V80M Series Axial Piston Variable Displacement Hydraulic PumpKey Characteristics:

- Variable Displacement Capability: The V80M series pump incorporates state-of-the-art variable displacement technology, allowing it to adjust the pump’s output based on system demand. This feature ensures optimal energy utilization, enhancing efficiency and reducing power consumption.

- High Performance and Power: With its exceptional design and engineering, the V80M series pump delivers outstanding performance and power. It operates seamlessly across various pressures and speeds, providing precise control and efficient power delivery for superior system performance.

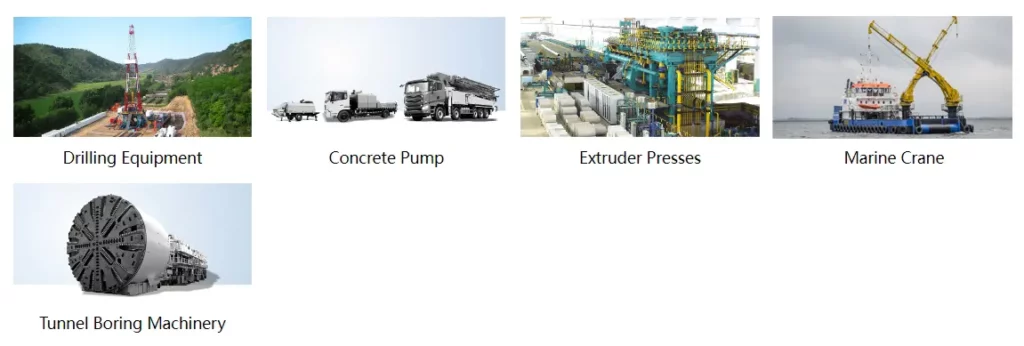

- Versatile Design for Diverse Applications: The V80M series pump is designed to adapt to various hydraulic systems and applications. It offers versatility in mounting options, fluid compatibility, and control methods, making it suitable for various industries and machinery.

- Enhanced Efficiency at Any Load: The variable displacement feature of the V80M series pump ensures efficiency across a broad range of loads. It minimizes energy losses and productivity, even under varying operating conditions by automatically adjusting the output to match the system’s requirements.

V80M Series Axial Piston Variable Displacement Hydraulic Pump Parameter:

| Size | Displacement cc/rev | Pressure bar | Rotation speed r/min | ||

| Rated | Peak | Max for self-priming*1 | Max*2 | ||

| V80ML200 | 202 | 400 | 450 | 2150 | 2550 |

V80M Series Axial Piston Variable Displacement Hydraulic Pump Advantages:

• Applied in open circuit hydraulic systems

• Oil suction available with boost mode

• High rotation speed

• High nominal pressure

• Compact structure, easy installation

• Provide sufficient torque for the rear pump when a tandem pump application is required

V80M Series Axial Piston Variable Displacement Hydraulic Pump Application:

Usage Method Of V80M Series Axial Piston Variable Displacement Hydraulic Pump:

- Installation and Integration: Select an appropriate location within the hydraulic system to install the V80M series axial piston variable displacement hydraulic pump. Ensure proper alignment and securely mount the pump using suitable brackets or accessories. Connect the pump to the hydraulic system using compatible fittings and hoses, ensuring leak-free connections.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the V80M series pump. Refer to the manufacturer’s recommended fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure optimal pump operation and longevity.

- Control and Adjustment: Familiarize yourself with the control options provided with the V80M series pump. Depending on the specific model, it may offer various control methods, such as manual, proportional, or electronic control. Understand the recommended control settings and adjust them accordingly to optimize pump performance.

- System Optimization: The V80M Series Pump allows system optimization by adjusting the pump’s displacement to match the load requirements. Take advantage of this feature to maximize energy efficiency and overall system performance.

How To Repair Hydraulic Cylinder?

Repairing a hydraulic cylinder requires careful assessment, identification of the problem, and appropriate steps to address the issue. Here is a general guide to help you repair a hydraulic cylinder:

- Safety First: Before starting any repair work, ensure the hydraulic system is depressurized, and the hydraulic fluid is drained completely. Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect yourself from hazards.

- Identify the Problem: Thoroughly inspect the hydraulic cylinder to identify the specific issue or damage. Common problems include leaking seals, damaged rods, worn-out bearings, or scoring on the cylinder bore. Understanding the problem will guide you in determining the necessary repair steps.

- Gather Tools and Replacement Parts: Gather the necessary tools and replacement parts based on the identified issue. This may include wrenches, sockets, pliers, a seal kit, new bearings, a hone, and a micrometer. Ensure that you have the correct parts that match the specifications of your hydraulic cylinder.

- Disassemble the Cylinder: Follow the steps outlined in the previous response on disassembling a hydraulic cylinder. Carefully remove the end caps, piston, rod assembly, and any other components to gain access to the damaged or faulty parts.

- Replace Seals and Bearings: If the issue is leaking or worn-out bearings, carefully remove the old seals and bearings from their respective locations. Clean the seal and bearing grooves thoroughly to remove any debris or buildup. Install new seals and bearings according to the manufacturer’s instructions, ensuring proper alignment and lubrication. Use appropriate tools to press the seals and bearings into place.

- Repair Damaged Rod or Cylinder Bore: If the rod or cylinder bore is damaged, it may require repair or replacement. Minor scratches or scoring on the rod can often be repaired by honing the surface with a hone tool. Measure the rod diameter using a micrometer to ensure it remains within the specified tolerances. If the damage is severe or exceeds allowable limits, the rod may need to be replaced.

Consult a professional hydraulic repair service or manufacturer for guidance for cylinder bore repair. They may recommend a honing process or, in some cases, re-sleeving the cylinder bore if the damage is extensive.

- Reassemble the Cylinder: Follow the reverse order of disassembly to reassemble the hydraulic cylinder. Ensure all components are properly aligned and secured. Lubricate the seals and parts with hydraulic fluid to ensure smooth operation.

- Test and Inspect: After reassembly, thoroughly inspect the repaired hydraulic cylinder. Pressurize the system gradually and check for any leaks or abnormal operations. Monitor the cylinder’s performance to ensure it functions as expected.

- Regular Maintenance: Establish a regular maintenance schedule to prolong the repaired hydraulic cylinder’s life. This may include periodic inspections, lubrication of seals, and monitoring fluid levels and quality. Adhering to preventive maintenance practices will help prevent future issues and maximize the cylinder’s lifespan.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: