EverPower-Huachang Production Capacity And Current Situation

EVERPOWER-HUACHANG Hydraulic Technology Co., LTD., as the leader of hydraulic system in forklift industry, has started its technological innovation journey since 1995. The company has secured its leading position in the international market with its excellent technical capability, leading research and development strength, unparalleled product quality and customer-oriented service concept.

Our company has accumulated rich production experience and optimized design data through long-term cooperation with cascade, kaup and Hangjian fittings. Many misunderstandings can be avoided in the design and production of new products, and the tooling process of production assembly and painting of hydraulic cylinders on site is very mature and reliable. Advanced equipment, advanced technology and mature design process, production process, enterprise management process, inspection process, storage and packaging process, details are as follows, for reference only:

Perfect Production Process Management

Cylinder Cleanliness Control Scheme

Cleaning Parts Before Welding

Clean The Cylinder Before Welding

Cylinder Cleaning Before Welding

Cleaning Valve Block Parts Before Welding

Clean The Whole Cylinder Body Before Assembly

Clean Small Parts Before Assembly

Clean The Piston Rod Before Assembly

Guide The Assembly Of Cylinder Bottom And Earring Parts

Piston Rod Assembly Operation Guidance (1)

Piston Rod Assembly Operation Guidance (2)

Cylinder Seal Installation Guide (1)

Cylinder Seal Installation Guide (2)

Recleaning And Finishing Of Piston Rod Assembly Before Assembly

Cylinder Assembly Process Instructions (1)

Cylinder Assembly Process Instructions (2)

Oil Cylinder Test Instruction Book (1)

Oil Cylinder Test Instruction Book (2)

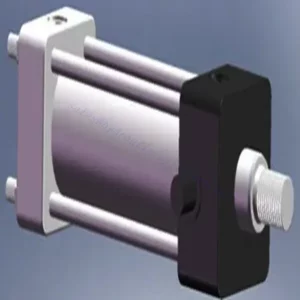

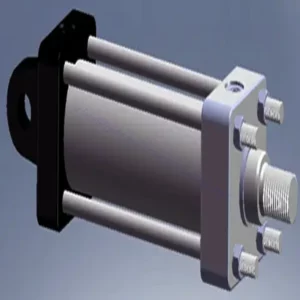

Arm cylinders play a vital role in various industrial applications, providing reliable linear motion and power. These cylinders are essential components in hydraulic and pneumatic systems, enabling machines to perform lifting, pushing, and pulling tasks with precision and strength.

Understanding their features, usage, and maintenance is crucial for optimizing performance and extending their lifespan.

Hydraulic Cylinder Production Area

Our company maintains a leading position in the international market with excellent technical capability, leading research and development strength, unparalleled product quality and customer-oriented service concept.

We employ leading production technology to ensure the precision and quality of our products, and have a responsive production supply chain and rich parts inventory to ensure our fast delivery capabilities.

Our company has accumulated rich production experience and optimized design data, and the tooling process of on-site production assembly and spray hydraulic cylinder is very mature and reliable. It has advanced equipment, advanced technology and mature design technology, production technology, enterprise management technology, inspection technology, storage and packaging technology.

Visit our VR hydraulic cylinder factory:

Metalworking Shop

Scraping And Rolling Machine

Cylinder Processing Machine

Turning And Milling Compound Machine

Double Station Turning And Milling Compound Machine

Machining Center

We use leading production technology to ensure the precision and quality of our products, and have a responsive production supply chain and rich parts inventory to ensure our fast delivery capabilities.

Turning And Milling Compound Machine

Double Station Turning And Milling Compound Machine

Machining Center

Robot Multi-Station Welder

Parts Assembly Purification Workshop

Our company has accumulated rich production experience and optimized design data, and the tooling process of on-site production assembly and spray hydraulic cylinder is very mature and reliable. It has advanced equipment, advanced technology and mature design technology, production technology, enterprise management technology, inspection technology, storage and packaging technology.

In addition, we also supply the following products: aerial work platform cylinders, industrial vehicle hydraulic cylinders, rotary drilling cylinders, mobile crane cylinders, construction machinery hydraulic cylinders, forklift hydraulic cylinders, mining dump truck cylinders, and sanitation machinery hydraulic cylinders, and welcome customers to customize with drawings or samples.

Bucket Cylinder For Sale

Applicable Models

Hydraulic Cylinder Spare Parts

Two Basic Types And Working Principles Of Hydraulic Cylinder

What Are The Key Components Of The Bucket Cylinder?

1. Cylinder Barrel

- Function: The cylinder barrel acts as the housing for the hydraulic fluid and piston. It facilitates the movement of the piston while containing the pressurized fluid.

- Materials: Typically constructed from high-strength steel or aluminum to endure high pressure and mechanical stress. Some designs may use composite materials for weight reduction.

- Design Considerations: The barrel must be precisely manufactured to ensure a tight fit with the piston, minimizing internal leakage and maximizing efficiency.

2. Piston

- Function: The piston moves within the cylinder barrel, converting hydraulic or pneumatic pressure into linear motion. It pushes or pulls the attached rod, which in turn moves the bucket.

- Materials: Often made from durable metals or composites that can withstand wear and tear. The surface may be treated for enhanced durability (e.g., chrome plating).

- Variations: Pistons can be designed as single-acting (force applied in one direction) or double-acting (force applied in both directions), depending on the application needs.

3. Rod

- Function: The rod connects the piston to the bucket and translates the piston’s movement into the desired action (lifting, lowering, tilting).

- Materials: Usually made from high-strength steel to handle tensile and compressive loads. It may also feature surface treatments to prevent corrosion and wear.

- Length and Diameter: The rod’s dimensions are critical for achieving the required stroke length and load capacity, affecting the overall performance of the cylinder.

4. End Caps

- Function: End caps seal the cylinder barrel at both ends, keeping the hydraulic fluid contained and protecting internal components from contaminants.

- Materials: Typically made from steel or aluminum, similar to the barrel. They may include threaded or bolted connections for easy assembly and disassembly.

- Design: End caps house the seals and ports, ensuring a tight fit and proper alignment of the internal components.

5. Seals and Gaskets

- Function: Seals prevent hydraulic fluid from leaking out of the cylinder and keep contaminants from entering. They maintain pressure within the system.

- Materials: Commonly made from elastomers, such as nitrile or polyurethane, which provide flexibility and resistance to wear and chemicals.

- Types: Various types of seals may be used, including rod seals, piston seals, and wiper seals, each serving a specific purpose in maintaining system integrity.

6. Ports

- Function: Ports allow hydraulic fluid to flow into and out of the cylinder, facilitating the movement of the piston. They are essential for controlling the cylinder’s operation.

- Design: Ports can be threaded or flange-mounted, depending on the hydraulic system design. They must be precisely machined to ensure a leak-free connection.

- Control: The flow of fluid through the ports is regulated by control valves, enabling operators to direct the motion of the bucket accurately.

7. Mounting Brackets

- Function: Mounting brackets secure the bucket cylinder to the machinery, providing stability during operation and ensuring proper alignment.

- Materials: Often made from high-strength steel to withstand the forces exerted during operation.

- Design Considerations: Brackets must be designed to accommodate the specific mounting points on the machinery, allowing for easy installation and adjustment.

8. Pressure Relief Valve (Optional)

- Function: The pressure relief valve protects the hydraulic system from excessive pressure buildup, which can lead to cylinder failure or damage to other components.

- Operation: It opens at a predetermined pressure, allowing excess fluid to escape and maintaining safe operating conditions.

- Importance: Including a pressure relief valve enhances safety and reliability, especially in high-demand applications.

What Materials Are Typically Used In The Construction Of Bucket Cylinders?

4. Sealing Materials

- Description: Various elastomers and polymers are used for seals and gaskets within the cylinder.

- Common Types: Nitrile rubber, polyurethane, and fluorocarbon compounds are often used for their flexibility and resistance to hydraulic fluids.

- Properties: These materials must withstand pressure, wear, and exposure to hydraulic fluids without degrading.

5. Plastics and Composites

- Description: In some cases, plastics or composite materials may be used in non-structural components or for lightweight applications.

- Properties: These materials can offer corrosion resistance and lower weight but may not be suitable for high-stress components.

6. Coatings and Surface Treatments

- Description: Surface treatments, such as chrome plating or hard anodizing, are often applied to steel or aluminum components.

- Purpose: These coatings enhance corrosion resistance, reduce friction, and extend the lifespan of the cylinder by protecting against wear.

The construction of bucket cylinders involves several materials, each chosen for its specific properties to ensure durability, strength, and performance. Here are the primary materials typically used:

1. Steel

- Description: High-strength steel is commonly used for the cylinder barrel and rod due to its excellent tensile strength and resistance to wear.

- Properties: Steel can withstand high pressure and heavy loads, making it ideal for demanding applications. It is also relatively cost-effective.

- Types: Common grades include carbon steel and alloy steel, which may have added elements for improved performance.

2. Aluminum

- Description: Aluminum is sometimes used for lighter applications where weight reduction is critical.

- Properties: It offers good strength-to-weight ratio, corrosion resistance, and is easier to machine than steel. However, it may not handle the same loads as steel.

3. Cast Iron

- Description: Cast iron can be used for components like end caps due to its excellent compressive strength.

- Properties: It is durable and resistant to wear but is heavier than steel or aluminum. Cast iron is also relatively brittle compared to steel.

How Does Bucket Cylinder Function in Hydraulic Systems?

The bucket cylinder functions as a crucial component in hydraulic systems, converting hydraulic energy into mechanical motion to operate machinery, particularly in applications like excavators and loaders. Here’s a detailed overview of how it works:

1. Hydraulic Fluid Dynamics

- Hydraulic Fluid: The system utilizes a hydraulic fluid (usually oil) that transmits power. This fluid is essential for creating pressure and force within the system.

- Pump Action: A hydraulic pump generates pressure by drawing hydraulic fluid from a reservoir and pushing it into the system. It creates a flow of fluid that is directed to the bucket cylinder.

2. Pressure Application

- Entering the Cylinder: When the operator activates the hydraulic controls (via joystick or lever), the pump directs pressurized fluid into the cylinder through inlet ports.

- Piston Movement: The pressurized fluid enters one side of the piston, causing it to move. The force exerted by the fluid pushes the piston, which in turn extends or retracts the rod connected to the bucket.

3. Mechanical Action

- Linear Motion: As the piston moves, it translates hydraulic energy into linear motion. This movement can lift, lower, or tilt the bucket, allowing for various operations such as digging, dumping, or leveling.

- Double-Acting Design: Many bucket cylinders are double-acting, meaning they can push and pull. When fluid is directed to one side of the piston, it extends; when directed to the other side, it retracts, providing full control over the bucket’s movements.

4. Control Mechanisms

- Valves: Control valves regulate the flow of hydraulic fluid into and out of the cylinder. They allow the operator to control the direction and speed of the bucket cylinder’s movement.

- Flow Control: By adjusting the flow rate of the hydraulic fluid, operators can control how quickly the bucket moves, enabling precise handling of materials.

5. Return to Reservoir

- Exiting the Cylinder: When the operator changes the control input, fluid is directed out of the cylinder through the outlet ports, returning to the hydraulic reservoir.

- Pressure Release: As fluid exits, it reduces pressure on one side of the piston, allowing it to return to its original position, ready for the next operation.

6. Safety Features

- Pressure Relief Valve: Many systems include a pressure relief valve that prevents excessive pressure buildup. If the pressure exceeds a certain threshold, the valve opens, allowing fluid to escape and protecting the system from damage.

7. Applications

- Construction Equipment: In excavators and loaders, bucket cylinders enable operators to efficiently handle heavy materials, perform digging tasks, and manage site operations.

- Material Handling: In agriculture and industrial settings, bucket cylinders assist in loading and unloading materials, making them essential for various tasks.