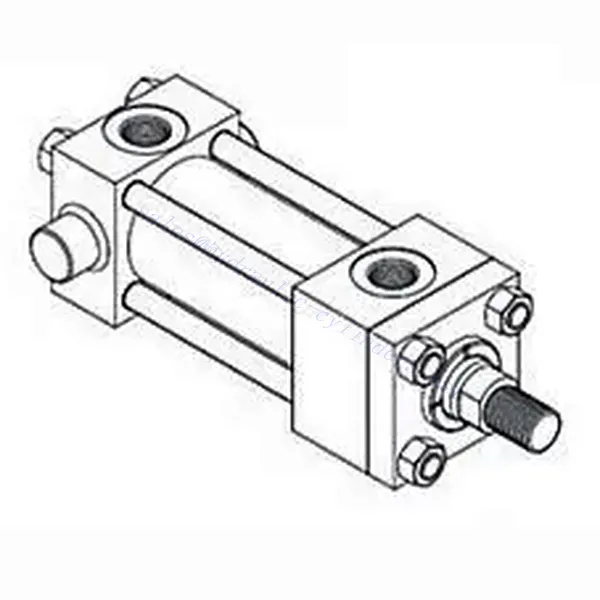

中间固定耳轴四连杆液压缸

中间固定耳轴四连杆液压缸

The middle fixed trunnion four rod hydraulic cylinder is a state-of-the-art hydraulic component designed to deliver exceptional power, stability, and precision in a wide range of industrial applications. With its innovative middle fixed trunnion design and four rod configuration, this four rod hydraulic cylinder offers superior load-bearing capacity, durability, and reliable performance, making it an essential asset in demanding hydraulic systems.

Essential Characteristics Of Four Rod Hydraulic Cylinder:

Middle Fixed Trunnion Design:

-

- The intermediate fixed trunnion design provides a safe and stable installation solution that ensures reliable operation even under heavy loads and extreme conditions.

- It simplifies the installation process and can be easily integrated into various hydraulic systems or equipment.

Four Rod Configuration:

-

- The four rod configuration enhances the bearing capacity of the cylinder, providing optimal stability and precise positioning.

- It enables the cylinder to effectively withstand side loads, providing exceptional resistance to torsion and lateral forces.

High Power Output:

-

- This four rod hydraulic cylinder has an impressive power output, allowing it to handle heavy loads easily.

- It provides superior power and thrust, making it suitable for applications requiring strength and lifting capacity.

Precise Control:

-

- The four rod hydraulic cylinder with a fixed trunnion in the middle can accurately control the linear movement to ensure accurate positioning and smooth operation.

- It provides excellent stroke control, enabling operators to achieve the speed and precision required for specific tasks.

Middle Fixed Trunnion Four Rod Hydraulic Cylinder Parameter:

中间固定耳轴四连杆液压缸 Usage Method:

Mounting and Installation:

-

- Consider load requirements and space constraints to determine the appropriate installation location of the four rod hydraulic cylinder within the system or equipment.

- Ensure the mounting surface is clean, level, and able to support the weight of the cylinder.

- Secure the middle fixing trunnons to the mounting surface using recommended bolts or fasteners.

Hydraulic Connections:

-

- Connect the hydraulic supply line to the cylinder port, ensuring proper seal to prevent leakage.

- Follow the manufacturer’s recommendations for the type of hydraulic oil and fill the system to the recommended level.

Operation:

-

- Activate the hydraulic system and control the movement of the cylinder using a hydraulic control valve or other suitable control mechanism.

- Adjust flow and pressure Settings to achieve the desired speed and force output.

- Regularly monitor cylinder operation for abnormal behavior, such as leakage, overheating, or unusual noise.

中间固定耳轴四连杆液压缸 Maintenance:

定期检查:

-

- Perform routine visual inspections to check for signs of wear, leakage, or damage.

- Inspect rod surfaces, seals, and mounting connections for abnormalities and address any problems promptly.

润滑:

-

- Follow the manufacturer’s lubrication interval guidelines and use the recommended lubricant to ensure smooth operation.

- Lubricate rods, seals, and other moving parts to reduce friction and extend the service life of four-bar hydraulic cylinders.

更换密封件:

-

- Over time, seals may wear out and need to be replaced. If a leak is detected, carefully remove the old seal and install the new seal according to the manufacturer’s specifications.

How Fast Can A Hydraulic Cylinder Move?

The speed at which a hydraulic cylinder can move depends on several factors, including the size and design of the cylinder, the hydraulic system’s pressure and flow rate, and the load being moved.

In general, hydraulic cylinders are known for their ability to provide both high force and precise control, but their maximum speed is typically lower compared to other types of actuators. The speed of a hydraulic cylinder is determined by the rate at which hydraulic fluid is supplied to or released from the cylinder chamber.

Here are a few factors that can affect the speed of a hydraulic cylinder:

- System Design and Components: The design of the hydraulic system, including the pump, valves, and piping, can impact the speed of the cylinder. The system should be properly sized and configured to provide adequate flow rate and pressure to achieve the desired speed.

- Cylinder Diameter and Stroke Length: The diameter and stroke length of the cylinder also play a role in determining its speed. Generally, larger diameter cylinders tend to move more slowly than smaller ones due to the more extensive hydraulic fluid required to fill or empty the cylinder chamber.

- Flow Rate and Pressure: The flow rate and pressure of the hydraulic fluid supplied to the cylinder are critical factors in determining the cylinder’s speed. Increasing the flow rate or pressure can result in faster movement, while reducing them will slow down the cylinder.

- Load and Friction: The weight and friction of the shipment being moved can affect the speed of the cylinder. Heavier loads may require more force, which can reduce the overall rate of the cylinder. Additionally, increased friction within the system, such as from seals or misalignment, can also impact the speed.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best light four rod hydraulic cylinder manufacturers. We can offer comprehensive light four rod hydraulic cylinder stock. We also provide corresponding 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: