HRP Radial Piston Hydraulic Motor

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

HRP Radial Piston Hydraulic Motor

The HRP radial piston hydraulic motor is a remarkable solution designed to deliver superior performance and reliability in various hydraulic applications. With its advanced engineering and exceptional features, this motor is poised to revolutionize hydraulic systems.

The HRP radial piston hydraulic motor is a powerful and efficient solution that delivers exceptional performance in various hydraulic applications. With its high power density, efficient operation, and wide speed range, it offers versatility and reliability. By following the recommended usage methods and adhering to regular maintenance practices, the harp motor will continue to provide reliable and efficient operation. Experience the power and efficiency of the HRP radial piston hydraulic motor in your hydraulic system today.

HRP Radial Piston Hydraulic Motor Key Characteristics:

- High Power Density:

- The HRP radial piston hydraulic motor boasts a high power density, allowing it to deliver impressive torque and power output in a compact size.

- This feature enables the motor to handle demanding applications while minimizing space requirements.

- Efficient Performance:

- The motor’s radial piston design optimizes energy efficiency, ensuring minimal energy losses during operation.

- This efficiency translates to reduced fuel consumption, lower operating costs, and enhanced overall system performance.

- Excellent Starting Torque:

- The HRP motor exhibits exceptional starting torque, making it suitable for applications that require rapid acceleration or heavy load starting.

- Its robust design and precise engineering enable it to generate significant torque even in challenging operating conditions.

- Wide Speed Range:

- The HRP motor offers a wide speed range, providing flexibility to adapt to various application requirements.

- Operators can adjust the motor’s speed to achieve optimal performance, productivity, and control over the hydraulic system.

HRP Radial Piston Hydraulic Motor Parameter:

| Specification | 160 | 225 | 255 | 280 | 325 | 365 | 400 | |

| Displacement cm3/rev | 160 | 225 | 255 | 280 | 325 | 365 | 400 | |

| Direction of rotation | Clockwise, Counter clockwise | |||||||

| Input torque rating Nm | Rated torque | 562 | 799 | 899 | 987 | 1145 | 1296 | 1416 |

| Max. torque | 1018 | 1435 | 1627 | 1786 | 1842 | 2073 | 2271 | |

| Unit theoretical torque | 22 | 32 | 36 | 39 | 46 | 52 | 57 | |

| Speed rpm | Min. stable speed | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Max. speed (Single speed) | 672 | 478 | 424 | 387 | 325 | 298 | 273 | |

| Max. speed (Double speed) | 878 | 624 | 554 | 504 | 427 | 389 | 352 | |

| Rated power kW | 18 | 18 | 18 | 18 | 18 | 18 | 18 | |

| Weight kg | 23 | 23 | 23 | 23 | 23 | 23 | 23 | |

| Pressure bar | Rated preesure | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Max. differential pressure | 450 | 450 | 450 | 450 | 400 | 400 | 400 | |

| Max. pressure at oil port A or B | 470 | 470 | 470 | 470 | 420 | 420 | 420 | |

| Max. case drain pressure | 10 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Hydraulic oil | Hydraulic fluids according to DIN 51 524 (HLP) | |||||||

| Oil viscosity mm2/s | 10~2000 | |||||||

| Oil temperaturex ℃ | -20 ~ 85 | |||||||

| Oil cleanliness | ISO 4406 20/18/15 | |||||||

| Brakes | Min. static torque Nm | 2200 | ||||||

| Min. release pressure bar | 11 | |||||||

| Max. release pressure bar | 15 | |||||||

| Max. pressure at oil port Z bar | 30 | |||||||

| Brake release minimum oil volume cm3/min | 23 | |||||||

| Weight kg | 9 | |||||||

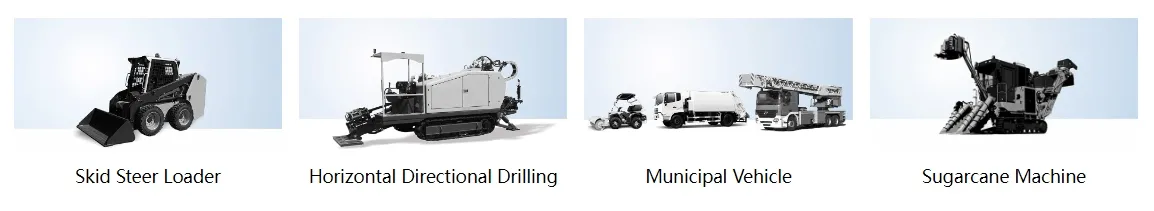

HRP Radial Piston Hydraulic Motor Application:

Usage Method Of HRP Radial Piston Hydraulic Motor:

- Mounting:

- Identify the appropriate mounting location for the HRP radial piston hydraulic motor within the hydraulic system.

- Ensure the mounting surface is clean, flat, and capable of securely supporting the motor’s weight.

- Utilize suitable mounting brackets or accessories to attach the motor to the designated location securely.

- Shaft Connection:

- Connect the motor’s output shaft to the driven component, such as a gearbox, pulley, or other mechanical systems.

- Ensure proper alignment and secure the connection with compatible couplings or adapters.

- Follow the manufacturer’s guidelines for recommended torque specifications during the shaft connection process.

- Hydraulic Connections:

- Identify the hydraulic ports on the HRP Motor for the supply and return lines.

- Select appropriate hydraulic hoses and fittings that match the motor’s specifications.

- Use proper sealing techniques to ensure secure connections between the hydraulic lines and the motor.

- System Integration:

- Integrate the HRP Motor into the hydraulic system by connecting it to other components such as pumps, valves, and actuators.

- Ensure compatibility and proper sizing of all components to achieve optimal system performance.

How To Repack Hydraulic Cylinder?

Repacking a hydraulic cylinder involves disassembling the cylinder, replacing the seal or seals, and reassembling the cylinder. Here is a step-by-step guide on how to repack a hydraulic cylinder:

- Safety Precautions:

- Ensure the hydraulic system is depressurized. Turn off the power source and relieve any residual pressure by operating the control valve several times.

- Put on appropriate personal protective equipment, including gloves and safety glasses.

- Cylinder Removal:

- Detach the hydraulic cylinder from the equipment or machinery. This process may involve removing mounting bolts or pins, depending on the specific setup.

- Support the cylinder during removal to prevent it from falling or causing damage.

- Cylinder Disassembly:

- Place the cylinder on a clean and stable work surface.

- Remove the cylinder head or cap using the appropriate tools, such as wrenches or sockets.

- Carefully slide out the piston and the piston rod from the cylinder barrel.

- Seal Removal:

- Identify the seals that need to be replaced. Common seals include the piston seal, rod seal, and wiper seal.

- Use a seal removal tool or a small flat-head screwdriver to carefully remove the old seals, taking care not to damage the cylinder surfaces.

- Cleaning and Inspection:

- Thoroughly clean all the disassembled components using a suitable solvent to remove dirt, debris, and old hydraulic fluid.

- Inspect the cylinder barrel, piston, piston rod, and other parts for signs of wear, scoring, pitting, or further damage. Replace any damaged components.

- Seal Replacement:

- Lubricate the new seals with hydraulic oil or a compatible seal lubricant.

- Install the new seals in their grooves, ensuring they are correctly seated and oriented according to the manufacturer’s instructions.

- Take care not to pinch or damage the seals during installation.

- Reassembly:

- Reinsert the piston and piston rod into the cylinder barrel, ensuring they are aligned correctly.

- Apply a thin layer of hydraulic oil or seal lubricant to the cylinder head, cap threads, and O-ring (if applicable).

- Carefully thread the cylinder head or cap back onto the barrel, ensuring it is tightened to the manufacturer’s specified torque.

- Cylinder Installation:

- Reattach the hydraulic cylinder to the equipment or machinery, following the appropriate mounting procedures.

- Ensure all connections are secure and properly tightened.

- Verify that the cylinder is properly aligned and positioned for optimal operation.

- Testing and Inspection:

- Restore the hydraulic system’s pressure and check for leaks around the repacked cylinder.

- Operate the cylinder through its full range of motion to ensure smooth operation.

- Monitor the cylinder for any abnormal noises, vibrations, or performance issues.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: