V33D Series Axial Piston Variable Displacement Hydraulic Pump

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

V33D Series Axial Piston Variable Displacement Hydraulic Pump

The V33D series axial piston variable displacement hydraulic pump is a revolutionary product designed to elevate the performance and efficiency of hydraulic systems. With its advanced features, precise control, and durable construction, this hydraulic pump sets new standards in the industry.

The V33D series axial piston variable displacement hydraulic pump is a game-changer in hydraulic systems. Its variable displacement capability, high performance, and versatile design offer precise control, enhanced efficiency, and exceptional power delivery. By following the recommended usage methods and adhering to regular maintenance practices, the V33D series hydraulic pump will continue to deliver outstanding performance, efficiency, and reliability. Embrace the power and efficiency of the v33d series axial piston variable displacement hydraulic pump to unlock the full potential of your hydraulic system.

V33D Series Axial Piston Variable Displacement Hydraulic Pump Key Characteristics:

- Variable Displacement Capability: The V33D series hydraulic pump features cutting-edge variable displacement technology, allowing it to adjust its output to match the system’s demand. This feature ensures optimal energy utilization, improving efficiency and reducing power consumption.

- High Performance and Power: With its exceptional design and engineering, the V33D series hydraulic pump delivers outstanding performance and power. It operates seamlessly across various pressures and speeds, providing precise control and efficient power delivery for superior system performance.

- Versatile Design for Diverse Applications: The V33D series hydraulic pump is designed to adapt to various hydraulic systems and applications. It offers versatility in mounting options, fluid compatibility, and control methods, making it suitable for multiple industries and machinery.

- Enhanced Efficiency at Any Load: The variable displacement feature of the V33D series hydraulic pump ensures efficiency across a broad range of loads. It minimizes energy losses and productivity, even under varying operating conditions, by automatically adjusting the output to match the system’s requirements.

V33D Series Axial Piston Variable Displacement Hydraulic Pump Parameter:

| Size | Displacement cc/rev | Pressure bar | Rotation speed r/min | ||

| Rated | Peak | Max for self-priming*1 | Max*2 | ||

| V33D | 250 | 350 | 420 | 2000 | 2000 |

V33D Series Axial Piston Variable Displacement Hydraulic Pump Advantages:

• Applied in closed circuit hydraulic systems

• Low noise

• Multiple control modules

• Compact structure, high power densitys

• Long life, high self-priming rotation speed

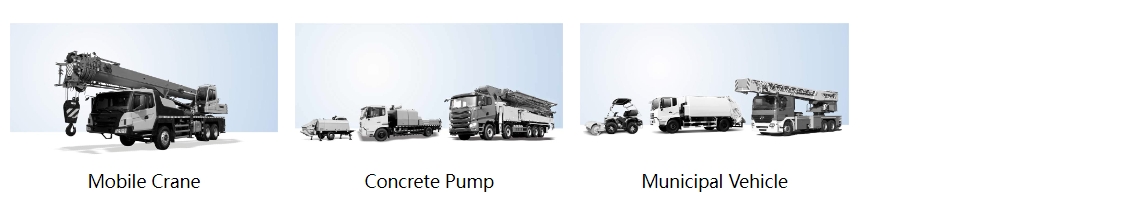

V33D Series Axial Piston Variable Displacement Hydraulic Pump Application:

Usage Method Of V33D Series Axial Piston Variable Displacement Hydraulic Pump:

- Installation and Integration: Select an appropriate location within the hydraulic system to install the V33D series axial piston variable displacement hydraulic pump. Ensure proper alignment and securely mount the pump using suitable brackets or accessories. Connect the pump to the hydraulic system using compatible fittings and hoses, ensuring leak-free connections.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the V33D series hydraulic pump. Refer to the manufacturer’s recommended fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure optimal pump operation and longevity.

- Control and Adjustment: Familiarize yourself with the control options provided with the V33D series hydraulic pump. Depending on the specific model, it may offer various control methods, such as manual, proportional, or electronic control. Understand the recommended control settings and adjust them accordingly to optimize pump performance.

- System Optimization: The V33D series hydraulic pump allows system optimization by adjusting the pump’s displacement to match the load requirements. Take advantage of this feature to maximize energy efficiency and overall system performance.

How A Hydraulic Cylinder Works?

Replacing hydraulic cylinder seals is an important maintenance task that ensures the proper functioning of hydraulic systems. Here is a step-by-step guide on how to replace hydraulic cylinder seals:

- Preparation:

- Gather the necessary tools and equipment, including a seal kit, hydraulic oil, safety goggles, gloves, and a clean work area.

- Ensure the hydraulic system is depressurized. Follow the manufacturer’s instructions for proper depressurization and lockout/tagout procedures.

- Remove the Cylinder:

- Disconnect any hydraulic hoses or fittings connected to the cylinder.

- Remove the mounting bolts or pins that hold the cylinder in place.

- Carefully extract the cylinder from its housing or mounting location.

- Disassemble the Cylinder:

- Place the cylinder on a clean work surface and remove any external components, such as rod guards or wipers.

- Carefully disassemble the cylinder by removing the end cap or gland from the cylinder barrel or tube. Use appropriate tools, such as spanners or wrenches, to loosen and remove the retaining bolts or nuts.

- Once the end cap or gland is removed, the piston, rod, and seals will be accessible.

- Remove the Old Seals:

- Inspect the piston, rod, and cylinder barrel for any signs of damage or wear.

- Carefully remove the old seals using seal removal tools or picks. Take note of the seal arrangement and orientation for proper installation of the new seals.

- Clean and Prepare:

- Thoroughly clean the cylinder components using a suitable solvent to remove dirt, debris, and old seal remnants. Ensure all surfaces are clean and dry before proceeding.

- Install the New Seals:

- Refer to the manufacturer’s instructions and the seal kit for proper seal installation. Lubricate the new seals with hydraulic oil or a recommended seal lubricant.

- Carefully install the new seals onto the piston, rod, and cylinder barrel, ensuring they are correctly seated and aligned according to the seal arrangement and orientation.

- Reassemble the Cylinder:

- Reassemble the cylinder in the reverse order of disassembly. Start by attaching the end cap or gland to the cylinder barrel or tube and tightening the retaining bolts or nuts to the specified torque.

- Ensure all components, including seals, are correctly aligned and positioned perfectly.

- Reattach any external components, such as rod guards or wipers.

- Install the Cylinder:

- Carefully place the reassembled cylinder back into its housing or mounting location.

- Secure the cylinder by reinstalling the mounting bolts or pins and tightening them to the specified torque.

- Reconnect any hydraulic hoses or fittings to the cylinder, ensuring proper tightening and alignment.

- Test and Check for Leaks:

- Refill the hydraulic system with the recommended hydraulic oil to the appropriate level.

- Slowly pressurize the system and check for leaks around the newly replaced seals.

- Operate the hydraulic system through its full range of motion to ensure proper seal function and system performance.

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame kliente kodus ja välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Hüdrosilindri kasutamine: