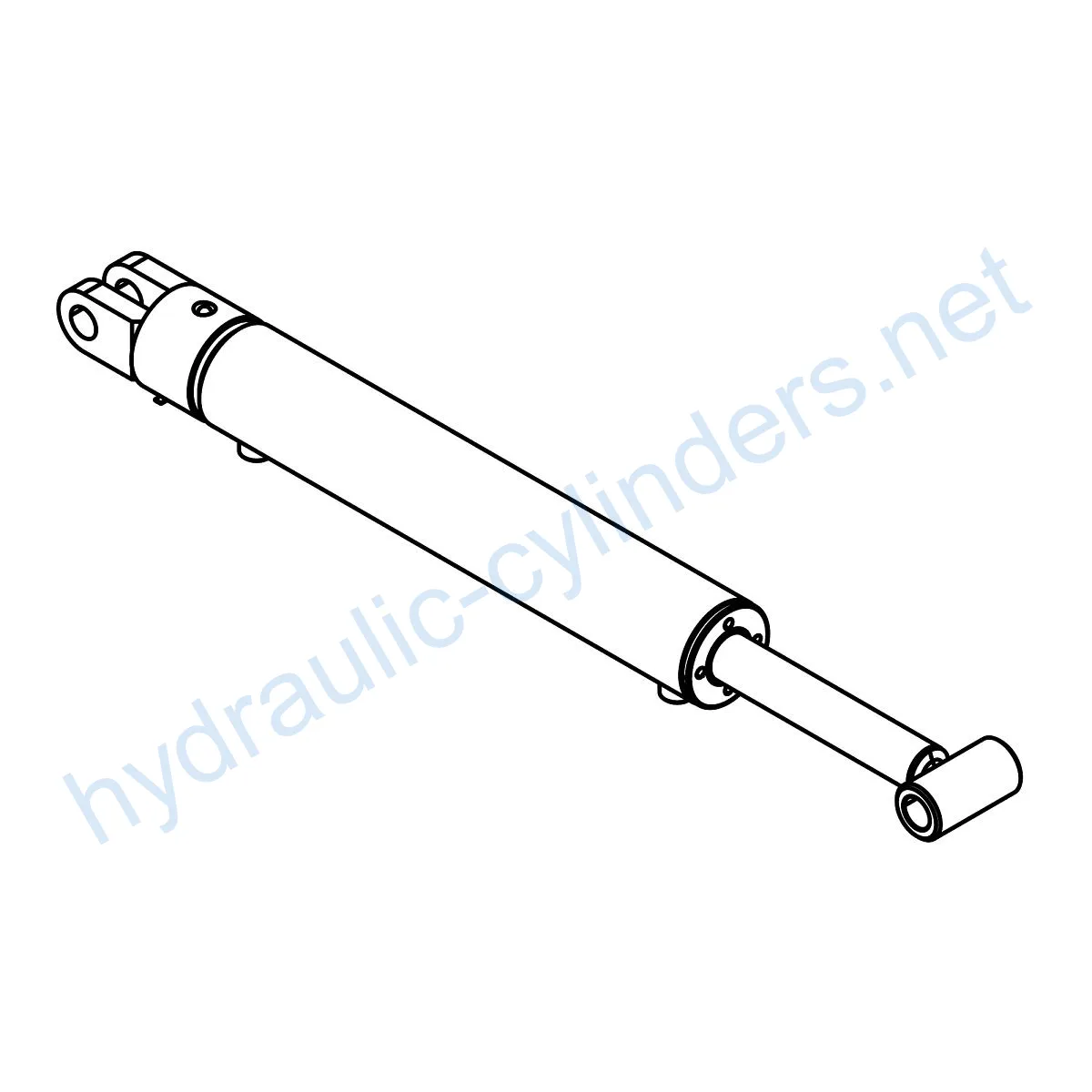

Replacement Of 5HG620106 Hydraulic Cylinder

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

Replacement Of 5HG620106 Hydraulic Cylinder

The Replacement Of 5HG620106 Hydraulic Cylinder is an essential component in various heavy-duty equipment. It is responsible for converting the energy of pressurized hydraulic fluid into mechanical force and motion. This hydraulic cylinder has a weight of 45.4 lb, a height of 4.5 in, and a length of 28.5 in which makes it compatible with various types of machinery.

Specifications and Compatibility

The Replacement Of 5HG620106 Hydraulic Cylinder has a weight of 45.4 lb, a height of 4.5 in, and a length of 28.5 in. This hydraulic cylinder is compatible with various types of heavy-duty equipment.

Features

-

Improved Equipment Performance

The Replacement Of 5HG620106 Hydraulic Cylinder can restore the normal operational capacity of the equipment by replacing damaged or worn hydraulic cylinders, ensuring its performance in various applications.

-

Enhanced Safety

Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failure, ensuring the safety of operators and equipment.

-

Overload Protection

New cylinder designs usually consider better overload protection mechanisms, improving safety.

-

Quick Installation

Modern hydraulic cylinders are usually designed for easy installation and replacement, reducing downtime.

-

Standardized Components

Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

We can produce this product and perfectly replace these hydraulic cylinders.

Applications

The Replacement Of 5HG620106 Hydraulic Cylinder is used in various heavy-duty equipment. Here are a few examples:

-

Excavators

The hydraulic cylinder in an excavator’s arm or bucket may become damaged due to long-term use or overload, requiring replacement to restore normal operation.

-

Cranes

The crane’s boom hydraulic cylinder is prone to wear during frequent lifting and lowering, requiring regular replacement to ensure safety.

-

Tractors

The front-end loader hydraulic cylinder of a tractor may leak or show reduced performance during continuous lifting and tilting operations, requiring replacement.

-

Harvesters

During harvesting, the hydraulic system is under high pressure, and the cylinder may be damaged due to fatigue, requiring timely replacement to maintain work efficiency.

-

Automated Production Lines

Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failure can affect production efficiency and requires immediate replacement.

-

Die Casting Machines

Hydraulic cylinders may show decreased performance under high pressure and temperature, and regular replacement can ensure product quality.

-

Mining Equipment

Hydraulic cylinders are used in mining equipment to lift and move heavy objects. Due to the harsh working environment, regular inspection and replacement are necessary to avoid equipment failure.

-

Bulldozers

The wear of the hydraulic cylinder on the bulldozer’s push arm can cause a decrease in pushing ability, requiring timely replacement to maintain work efficiency.

Huolto

Proper maintenance of the Replacement Of 5HG620106 Hydraulic Cylinder can help extend its lifespan. Here are some common maintenance tasks:

-

Regular Inspections

Regularly inspecting the hydraulic cylinder for wear and damage is crucial to identifying potential problems before they can cause major damage.

-

Lubrication

Add adequate hydraulic oil to lubricate the cylinder regularly.

-

Seal Replacement

Seals, such as piston seals and rod seals, need to be replaced periodically. Selecting seals made of wear-resistant materials such as polyurethane or nitrile rubber can improve durability.

-

Calibration Checks

Periodically check the calibration of the hydraulic cylinder to ensure that it is working correctly.

During installation, provide guidance on aligning the cylinder and recommend using proper installation brackets to secure the cylinder. Additionally, check, repair, and replacement procedures should be followed to provide better product life.

Safety and Environmental Factors

When using hydraulic cylinders, safety measures are essential. For example, use appropriate protective equipment and follow recommended work practices. Furthermore, hydraulic oil leaks can cause environmental pollution and should be avoided.

Diagnosis and Common Problems

The following are some common issues with hydraulic cylinders and their solutions:

-

Cylinder Drift

This problem is caused by a damaged piston seal or cylinder bore. Replace the piston seal and re-bore the cylinder to solve this issue.

-

Cylinder Leaks

The most common cause of cylinder leaks is worn piston seals or rod seals. Replace the seals to fix this issue.

-

Low Cylinder Speed

This problem can be due to insufficient fluid supply or a damaged cylinder. Check the fluid supply and replace the cylinder to solve this issue.

Preventive measures include proper maintenance, periodic inspection, and proper use, which can reduce the chances of these problems occurring.

Design Considerations and Selection Criteria

The following factors should be considered when designing and selecting hydraulic cylinders:

-

Load Capacity

The cylinder’s load capacity must match the equipment’s requirements. Overloading can damage the cylinder.

-

Sealing and Durability

The cylinder’s seals should be made of wear-resistant materials such as polyurethane or nitrile rubber and should be resistant to high temperatures and pressures. The cylinder body and thread end should undergo fine processing to improve wear resistance.

-

Safety

Cylinders with overload protection mechanisms should be selected to improve safety during operation.

-

Huolto

Easy to disassemble and replace cylinders should be selected to reduce downtime and maintenance costs.

Sealing and Lubrication

Proper sealing and lubrication can extend the lifespan of hydraulic cylinders. Use various seals such as piston seals and rod seals and select wear-resistant materials such as polyurethane or nitrile rubber for improved durability. Additionally, the cylinder body and thread end should undergo fine processing to improve wear resistance. Finally, add adequate hydraulic oil to lubricate the cylinder regularly.

Installation Guidelines

Proper installation is crucial for the performance of hydraulic cylinders. The following guidelines should be followed:

-

Align the Cylinder

The cylinder should be correctly aligned during installation.

-

Use Proper Brackets

The cylinder should be secured using appropriate installation brackets.

About Our Company

We are a manufacturer of replacement hydraulic cylinders with a complete range of products. We are one of the leading manufacturers and wholesale distributors of hydraulic cylinders in domestic and international markets. Our company provides customized services, has a professional team, and is certified internationally. We have advanced production equipment and provide excellent after-sales service.

Author: lyl

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Hydraulisylinteri Sovellus: