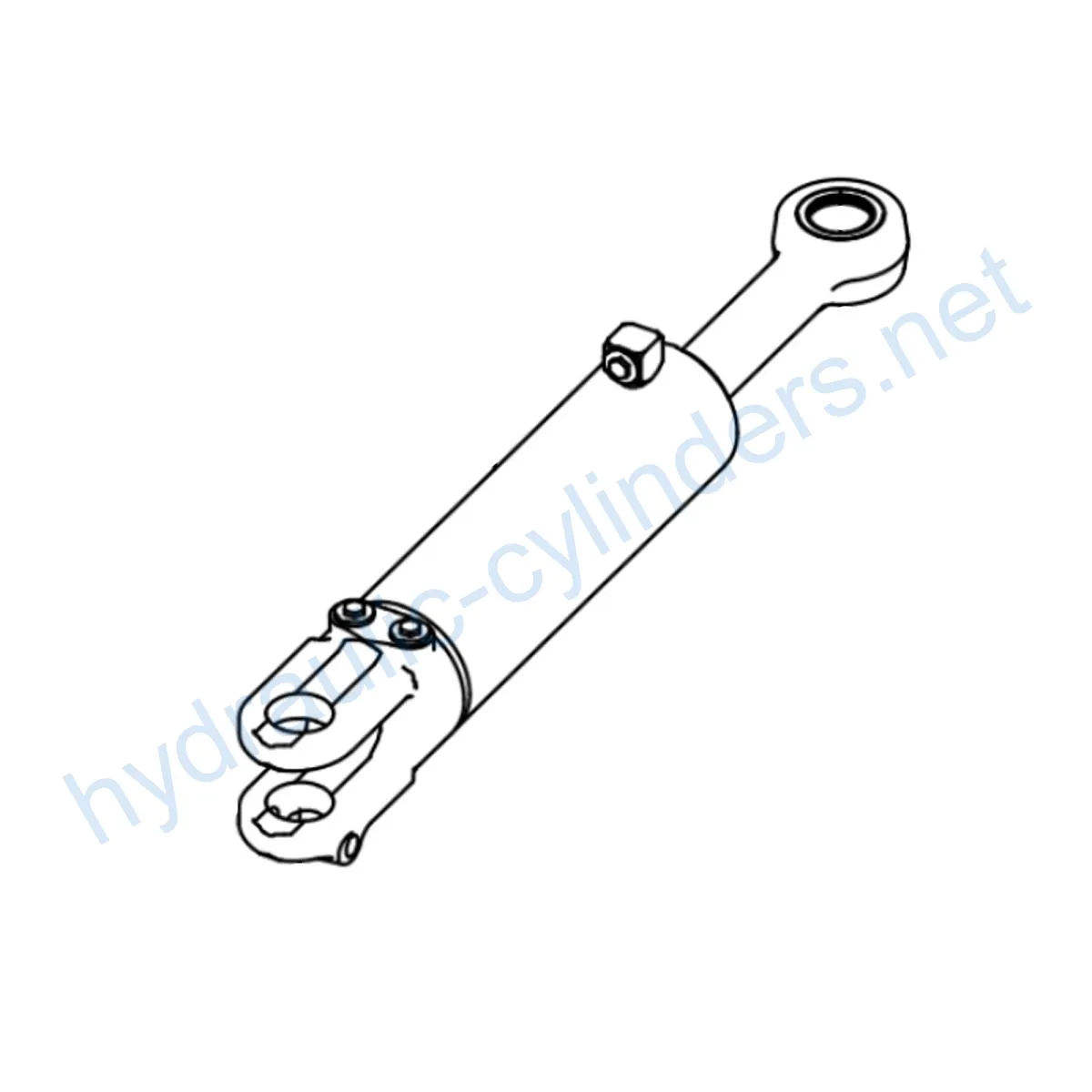

Replacement Of AHC20901 Hydraulic Cylinder

Mint a hidraulikus hengerek egyik gyártója, szállítója és exportőre a mechanikai termékek, kínálunk hidraulikus hengerek és sok más termék.

Kérjük, lépjen kapcsolatba velünk a részletekért.

Posta:sales@hydraulic-cylinders.net

Hidraulikus hengerek gyártója, szállítója és exportőre.

Product Introduction

The Replacement Of AHC20901 Hydraulic Cylinder is a hydraulic cylinder designed to replace damaged or worn-out cylinders in various types of equipment. It has a weight of 99.208 lb, a height of 11.7 in, a width of 12.5 in, and a length of 34 in. It is compatible with the following machine models: 620 P, 620G, 622 P, 622G, 670 P, 670G, 672 P, 672G, 770 P, 770G, 772 P, and 772G.

Specifications and Compatibility

The Replacement Of AHC20901 Hydraulic Cylinder is a universal cylinder that can replace damaged cylinders in a wide range of equipment models. Its compatibility with various machine models makes it a versatile choice for equipment owners and operators. The cylinder’s weight, height, width, and length are standardized, ensuring that it can fit and function properly in different types of equipment.

Features and Benefits

-

Improved equipment performance

Replacement of damaged or worn-out hydraulic cylinders can restore equipment’s normal operating capability and ensure its performance in various applications.

-

Enhanced safety

Regular replacement of hydraulic cylinders can reduce safety hazards caused by cylinder failures and ensure the safety of operators and equipment.

-

Overload protection

New cylinder designs typically incorporate better overload protection mechanisms, enhancing safety.

-

Quick installation

Modern hydraulic cylinders are designed to be easy to install and replace, reducing downtime.

-

Standardized components

Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts on the market.

Applications

The Replacement Of AHC20901 Hydraulic Cylinder is widely used in various types of equipment, including:

- Excavators

- Cranes

- Tractors

- Harvesters

- Automated production lines

- Die-casting machines

- Mining equipment

- Bulldozers

Here are three application scenarios:

-

Excavators

The hydraulic cylinder in excavator arms or buckets may become damaged due to long-term use or overload, requiring replacement to restore normal operation.

-

Cranes

The hydraulic cylinder in a crane’s lifting arm may wear out easily during frequent lifting and lowering, requiring regular replacement to ensure safety.

-

Tractors

The hydraulic cylinder in the front loading arm of a tractor may leak or lose performance during continuous lifting and tilting operations, requiring replacement.

Maintenance and Repair

Regular maintenance of the Replacement Of AHC20901 Hydraulic Cylinder is essential to ensure its optimal performance and longevity. Here are three essential maintenance tasks:

-

Regular inspection

The cylinder should be regularly inspected for any signs of damage or wear, such as leaks, cracks, corrosion, or bent rods.

-

Kenés

The cylinder and its components should be adequately lubricated to prevent friction and wear.

-

Seal replacement and calibration check

The cylinder’s seals should be periodically replaced to maintain proper sealing and prevent leaks. The cylinder should also be calibrated to ensure that it meets the required specifications.

Safety and Environmental Considerations

Ensuring safety when working with hydraulic cylinders is crucial. Adequate protection measures should be taken to prevent accidents, such as wearing protective gear and following proper procedures. Proper disposal of used hydraulic cylinders is also essential to prevent environmental pollution.

Troubleshooting and Common Problems

Here are some common problems you may encounter with the Replacement Of AHC20901 Hydraulic Cylinder:

- The cylinder is leaking

- The cylinder is making strange noises

- The cylinder is not functioning properly

To troubleshoot these problems, you should follow the recommended procedures for inspection, maintenance, and repair. For example, if the cylinder is leaking, you should check the seals and replace them if necessary. If the cylinder is not functioning correctly, you should examine its components and repair or replace them as needed.

Design Considerations and Selection Criteria

The Replacement Of AHC20901 Hydraulic Cylinder is designed to meet specific requirements, such as load-bearing capacity, durability, safety, and maintainability. Here are some design considerations and selection criteria:

-

Load-bearing capacity

The cylinder should have sufficient load-bearing capacity to support the equipment’s weight and withstand external forces and pressures.

-

Durability

The cylinder and its components should be durable enough to withstand wear, corrosion, and other forms of damage.

-

Safety

The cylinder should be designed to ensure safety during operation, such as incorporating overload protection mechanisms and proper sealing.

-

Maintainability

The cylinder should be easy to maintain and repair, such as using standardized components and providing accessible inspection points.

Sealing and Lubrication

The Replacement Of AHC20901 Hydraulic Cylinder uses various sealing components, such as piston seals and rod seals, to prevent leaks and ensure proper operation. Proper lubrication is also essential to prevent wear and reduce friction. Here are some sealing and lubrication considerations:

-

Sealing components

High-quality sealing components, such as polyurethane and nitrile rubber seals, should be used to ensure proper sealing and prevent leaks. The cylinder’s body and threads should also be treated to enhance wear resistance.

-

Kenés

The cylinder should be lubricated with the appropriate hydraulic oil to prevent friction and wear. The lubrication intervals and amounts should follow the manufacturer’s recommendations.

Installation Guidelines

Proper installation of the Replacement Of AHC20901 Hydraulic Cylinder is crucial to ensure its optimal performance and safety. Here are some installation guidelines:

-

Alignment and orientation

The cylinder should be aligned and oriented correctly with the equipment’s mounting points to ensure proper operation and prevent stress on the cylinder’s components.

-

Mounting and fixing

The cylinder should be securely mounted and fixed using appropriate mounting brackets and bolts to prevent movement and damage during operation.

-

Inspection and testing

The cylinder should be inspected and tested after installation to ensure proper operation and safety.

About Our Company

We are a leading manufacturer and wholesaler of hydraulic cylinders, providing a complete range of products to meet various customer needs. Our company is dedicated to providing high-quality cylinders, excellent customer service, and competitive pricing to our customers worldwide.

-

Professionalism

Our company has a team of experienced and skilled professionals who are committed to providing the best products and services to our customers.

-

International certification

Our products have obtained international certifications, such as ISO9001 and CE, ensuring their quality and safety.

-

Customization services

We offer customization services to meet specific customer requirements, such as designing and manufacturing customized hydraulic cylinders.

-

Production equipment

Our company uses advanced production equipment and testing instruments to ensure the quality and performance of our products.

-

After-sales service

We have a dedicated after-sales service team to provide timely support and solutions to our customers.

Author: lyl.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: