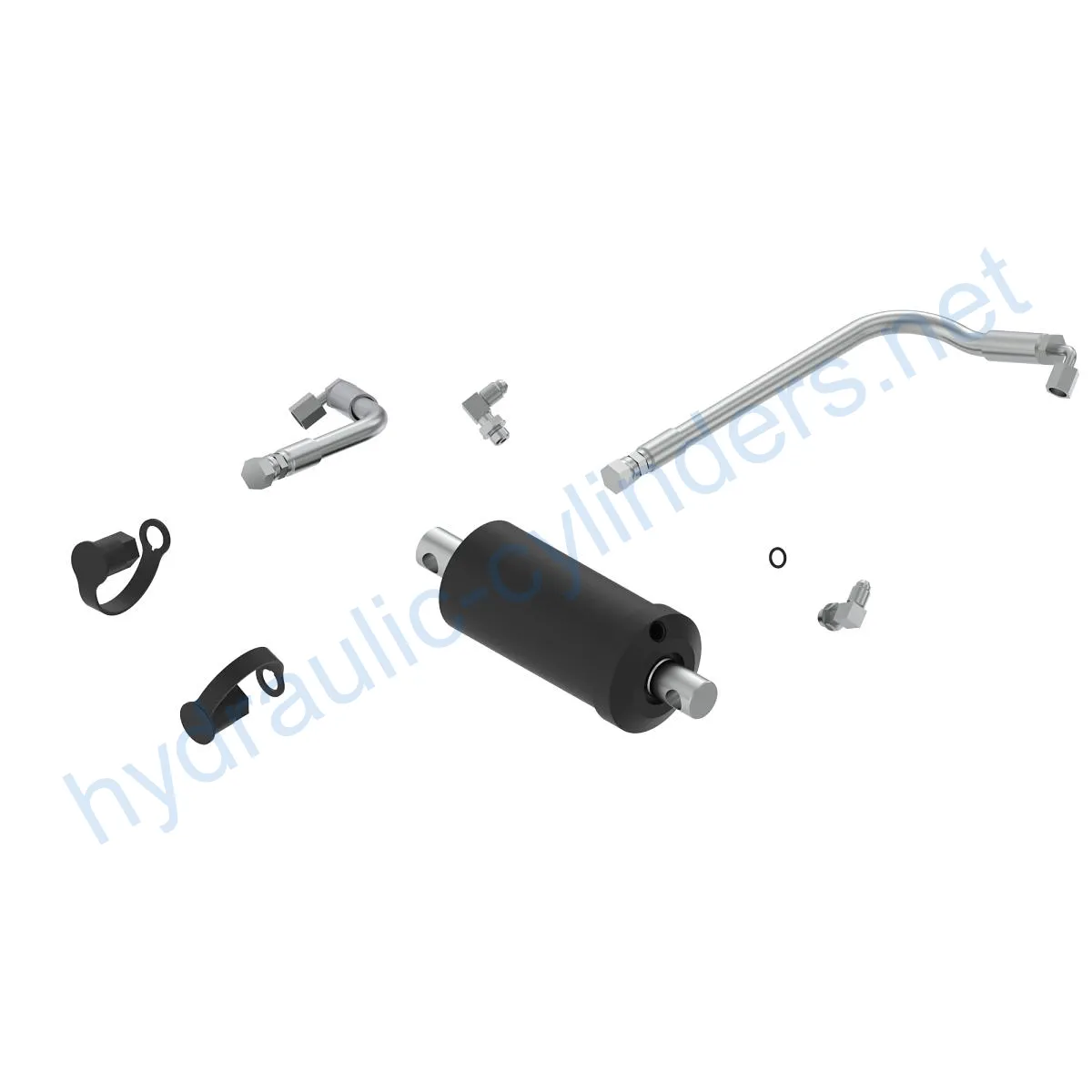

Replacement Of BM17650 Front Hitch Hydraulic Angling Cylinder Kit

Mint a hidraulikus hengerek egyik gyártója, szállítója és exportőre a mechanikai termékek, kínálunk hidraulikus hengerek és sok más termék.

Kérjük, lépjen kapcsolatba velünk a részletekért.

Posta:sales@hydraulic-cylinders.net

Hidraulikus hengerek gyártója, szállítója és exportőre.

Introduction

The Replacement Of BM17650 Front Hitch Hydraulic Angling Cylinder Kit is a crucial component for various models, including 26 44 IN. SNOW BLOWERS, 52 IN., 54 IN., and 60 IN. 246 FRONT BLADE. This hydraulic cylinder plays a vital role in the operation of these machines, ensuring optimal performance and functionality.

Specifications

- Weight: 8.057 lb

- Height: 5.2 in

- Width: 9.3 in

- Length: 9.5 in

- Volume: 0.075 gal

Features

- Improved Equipment Performance: Replacement of damaged or worn hydraulic cylinders restores the equipment’s normal operational capability, ensuring optimal performance in various applications.

- Enhanced Safety: Regular replacement of hydraulic cylinders reduces safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate improved overload protection mechanisms, enhancing overall safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it convenient to obtain replacement parts in the market.

We are capable of manufacturing this product, providing perfect replacements for these hydraulic cylinders.

Applications

Here are three examples of the applications of this hydraulic cylinder:

- Excavators: Hydraulic cylinders in excavator arms or buckets may get damaged due to prolonged use or overloading, requiring replacement to restore normal operations.

- Cranes: Hydraulic cylinders in crane jibs are prone to wear and tear during frequent lifting and lowering processes, necessitating regular replacement to ensure safety.

- Tractors: Hydraulic cylinders in front-end loader attachments of tractors may experience leaks or performance degradation due to continuous lifting and tilting operations, requiring replacement.

Maintenance Tasks

Here are three common maintenance tasks for the hydraulic cylinder:

- Regular Inspections: Periodic inspections are essential to identify any potential issues or abnormalities in the hydraulic cylinder.

- Proper Lubrication: Adequate lubrication with the recommended hydraulic oil is crucial to ensure smooth operation and extend the lifespan of the cylinder.

- Seal Replacement and Calibration Checks: Regularly replacing seals and performing calibration checks helps maintain optimal performance and prevent leakage.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is imperative to prioritize safety measures to prevent accidents and ensure the well-being of operators. Environmental factors, such as temperature and external debris, should also be taken into account to maintain cylinder performance and longevity.

Fault Diagnosis and Common Problems

It is important to be aware of potential faults and common issues that may arise with hydraulic cylinders. Here are some common problems:

- Leakage: Leaks can occur due to damaged seals or faulty connections. Regular inspections and timely seal replacements can help mitigate this issue.

- Performance Degradation: Over time, hydraulic cylinders may experience reduced performance, affecting the efficiency of the equipment. Rebuilding or replacing worn-out components can resolve this problem.

- Malfunctioning: Faulty operation, irregular movements, or unresponsiveness may indicate internal cylinder problems. Troubleshooting techniques should be employed to diagnose and address these malfunctions.

By following troubleshooting tips and implementing appropriate solutions, readers can effectively diagnose and resolve hydraulic cylinder issues. Precautionary measures can also be taken to minimize potential problems.

Design Considerations and Selection Criteria

When choosing hydraulic cylinders, several design considerations and selection criteria should be taken into account:

- Load-Bearing Capacity: Hydraulic cylinders should be selected based on their ability to withstand the intended load without compromising performance.

- Sealing and Durability: High-quality seals and durable materials are essential to ensure effective sealing and prolonged cylinder lifespan.

- Safety: Cylinders should be designed with safety features to prevent accidents or system failures.

- Maintenance: Easy access for maintenance, including disassembly and component replacement, is crucial for efficient upkeep of hydraulic cylinders.

Sealing and Lubrication

Hydraulic cylinders utilize various sealing components, such as piston seals and rod seals, made from wear-resistant materials like polyurethane and nitrile rubber. The cylinder body and threaded ends undergo meticulous surface treatment to enhance wear resistance. Regular lubrication with the appropriate hydraulic oil is necessary to ensure smooth operation and reduce friction.

Regular Inspection and Preventive Maintenance

Regular inspections and preventive maintenance play a vital role in maximizing the longevity and performance of hydraulic cylinders. Proper installation, lubrication, and adjustment are crucial. During installation, it is important to provide proper cylinder alignment guidance, recommend the use of suitable mounting brackets for securing the cylinder, and suggest inspection, repair, and replacement procedures. We provide replacement parts and rebuilding services to improve the lifespan of the hydraulic cylinder.

Installation Guide

Proper installation of the hydraulic cylinder is essential for optimal performance and safety. Here are some guidelines:

- Ensure correct alignment of the cylinder during installation.

- Use appropriate installation brackets to secure the cylinder.

- Follow recommended inspection, repair, and replacement procedures.

- Utilize rebuilding services and replacement components to extend the cylinder’s lifespan.

About Our Company

We are a manufacturer specializing in replacement hydraulic cylinders, offering a wide range of product varieties. As one of the leading manufacturers and wholesale distributors of hydraulic cylinders in the domestic and international markets, we are committed to providing high-quality products.

Our company stands out due to:

- Professionalism

- International certifications

- Customization services

- State-of-the-art production equipment

- Outstanding after-sales service

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: