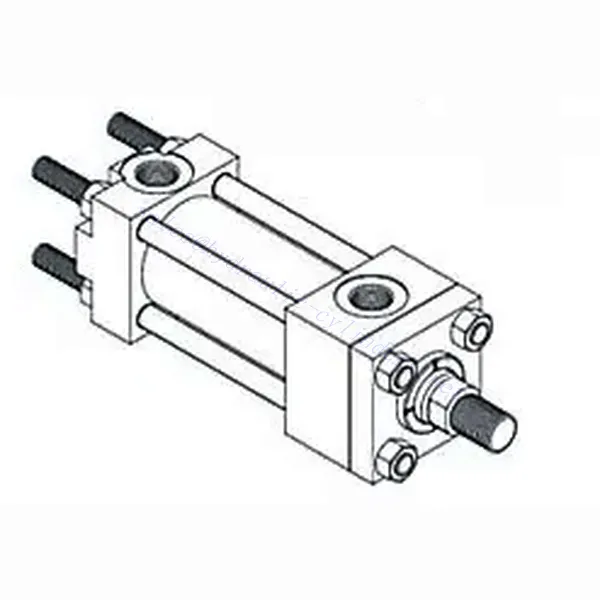

TC típusú négy rúd hidraulikus henger

Mint a hidraulikus hengerek egyik gyártója, szállítója és exportőre a mechanikai termékek, kínálunk hidraulikus hengerek és sok más termék.

Kérjük, lépjen kapcsolatba velünk a részletekért.

Posta:sales@hydraulic-cylinders.net

Hidraulikus hengerek gyártója, szállítója és exportőre.

TC típusú négy rúd hidraulikus henger

The type TC four rod hydraulic cylinder is a powerful and versatile component vital in various industrial applications. Designed for optimum performance, precise control, and superior durability, the hydraulic cylinder is designed to handle demanding tasks easily. This paper will discuss the main characteristics, use methods, and maintenance guidelines of the TC four rod hydraulic cylinder.

Essential Characteristics Of Four Rod Hydraulic Cylinder:

The TC type four rod hydraulic cylinder offers several notable features that make it a preferred choice in the hydraulic industry:

Enhanced Stability and Load-Bearing Capacity:

- The four rod design provides superior stability by evenly distributing the load throughout the cylinder. This design minimizes deflection and ensures consistent performance even under heavy loads and challenging conditions.

- The load-carrying capacity of the four rod hydraulic cylinder is increased, making it suitable for applications involving high forces and large loads.

Precise Control and Positioning:

- With its four rod configuration, the TC-type four rod hydraulic cylinder enables precise control and positioning of the piston rod. This feature ensures accurate movement and alignment of loads, allowing specific and synchronous operations.

- The precise control provided by the cylinder makes it ideal for applications that require precise motion control, such as robotics, material handling, and automation systems.

Durability and Longevity:

- Tc-type cylinders are built to withstand harsh environments and heavy use. It is made of high-quality materials that provide superior strength, durability, wear, and corrosion resistance.

- The cylinder’s rugged construction ensures longevity and reliable performance, reducing downtime and maintenance costs.

TC Type Four Rod Hydraulic Cylinder Parameter:

TC típusú négy rúd hidraulikus henger Felhasználási módszer:

Mounting and Connection:

- Ensure proper alignment and secure cylinder mounting to the equipment or machinery using suitable bolts or fasteners.

- Use appropriate bolts or fasteners to ensure the cylinders are correctly aligned and secured to the equipment or machine.

Hydraulic Control:

- Activate the hydraulic system that powers the cylinder by operating the associated hydraulic pump or control valve.

- The control valve adjusts the hydraulic flow and pressure to control the movement of the cylinder. This allows precise positioning and operation of the hydraulic cylinder.

TC típusú négy rúd hidraulikus henger Karbantartás:

Proper TC type four rod hydraulic cylinder maintenance ensures optimal performance and extends lifespan. Consider the following maintenance tips:

Regular Inspection:

- Check the cylinder regularly for leaks, damage, or excessive wear. Pay attention to seals, tie rods, and mounting parts.

- Replace any worn or damaged parts promptly to prevent further problems and ensure optimal performance.

Lubrication:

- Lubricate intervals as recommended by the manufacturer. Apply high quality hydraulic oil or grease to rods, seals, and other moving parts.

- Proper lubrication can reduce friction, and wear, and ensure smooth operation of the hydraulic cylinder.

Cleanliness:

- Keep four rod hydraulic cylinders and their surroundings clean and free of dirt, debris, or contaminants that affect performance.

- Use a mild cleaner and a soft cloth to remove accumulated dirt or grime periodically.

How To Replace Seals On A Hydraulic Cylinder?

Replacing seals on a hydraulic cylinder is a common maintenance task that helps restore proper functionality and prevent leaks. Here’s a step-by-step guide on how to replace seals on a hydraulic cylinder:

- Preparation and Safety:

- Gather the necessary tools and replacement seals specific to your hydraulic cylinder model.

- Ensure you are working in a safe and clean environment, wearing appropriate personal protective equipment.

- Cylinder Disassembly:

- Safely remove the hydraulic cylinder from the equipment or machinery installed in.

- Carefully disassemble the cylinder, following the manufacturer’s instructions or guidelines.

- Take note of the order in which the components are removed and consider taking pictures or making sketches for reference during reassembly.

- Seal Identification and Removal:

- Identify the seals that need replacement, such as piston seals, rod seals, or gland seals.

- Use suitable tools or techniques to remove the old seals. Standard methods include using seal removal picks, hooks, or compressed air to pry or push the seals out gently.

- Be cautious not to damage the cylinder walls or other components during removal.

- Cylinder Cleaning:

- Thoroughly clean the cylinder bore and all components using an appropriate cleaning solution to remove debris, dirt, or old lubricants.

- Use lint-free cloths or compressed air to dry the components thoroughly. Ensure no residue or contaminants are left behind.

- New Seal Installation:

- Lubricate the new seals with a compatible hydraulic fluid or assembly lubricant. This helps with ease of installation and initial seal conditioning.

- Carefully install the new seals into their grooves, ensuring they are correctly seated and aligned.

- Use a seal installation tool or soft-faced mallet to tap the seals into position gently. Take care not to damage the seals during installation.

- Reassembly and Testing:

- Begin reassembling the hydraulic cylinder, following the reverse order of disassembly. Refer to your pictures or sketches for guidance.

- Ensure all components are properly aligned and fitted together.

- Reinstall the hydraulic cylinder into the equipment or machinery.

- Connect the hydraulic lines and ensure all connections are secure.

- Test the hydraulic cylinder for proper function and operation. Activate the hydraulic system and operate the cylinder through its full range of motion.

- Monitor for any leaks, abnormal noises, or other issues during operation. If any problems arise, inspect the seals and connections for proper installation and address any issues accordingly.

A gyár kapacitása és kapacitása:

(1) Összeszerelés

Első osztályú független kutatási és fejlesztési összeszerelési platformmal rendelkezünk. A hidraulikus hengergyártó műhely négy félautomata emelőhenger-összeszerelő sorral és egy automata billenőhenger-összeszerelő sorral rendelkezik, tervezett éves gyártási kapacitása 1 millió darab. A speciális henger műhely különböző specifikációjú félautomata tisztító összeszerelő rendszerrel van felszerelve, amelynek tervezett éves termelési kapacitása 200.000, és híres CNC megmunkáló berendezéssel, megmunkáló központtal, nagy pontosságú hengerfeldolgozó speciális berendezéssel, robothegesztő géppel, automatikus tisztítógéppel, automatikus henger összeszerelő géppel és automatikus festési gyártósorral van felszerelve. A meglévő kritikus berendezések több mint 300 készlet (készlet). A berendezések erőforrásainak optimális elosztása és hatékony felhasználása biztosítja a termékek pontossági követelményeit és megfelel a termékek minőségi igényeinek.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best light four rod hydraulic cylinder manufacturers. We can offer comprehensive light four rod hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: