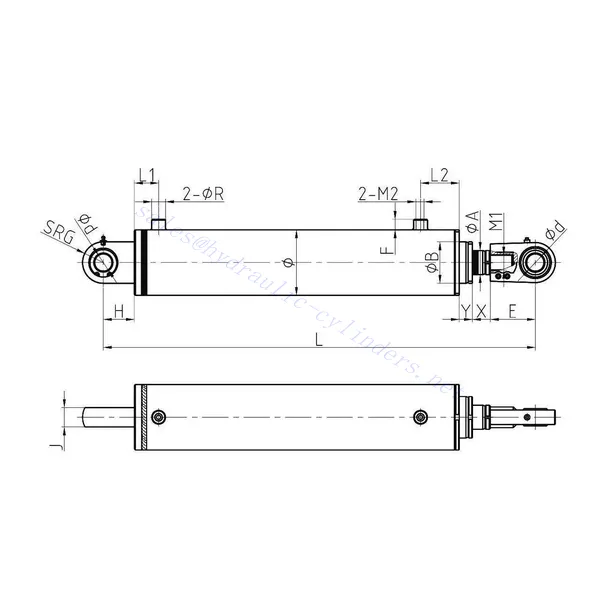

Earring Joint Two Stage Telescopic Hydraulic Cylinder

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

Earring Joint Two Stage Telescopic Hydraulic Cylinder

The earring joint two-stage telescopic hydraulic cylinder is a cutting-edge hydraulic device designed to provide efficient power transmission in a variety of industrial applications. With its innovative design, superior performance and versatility, this hydraulic cylinder offers precise control and increased productivity. Whether used in construction, material handling, or agricultural machinery, earring Joint two-stage telescopic hydraulic cylinders are designed to optimize hydraulic operation and provide outstanding results.

CX series compact cylinders are used for clamping cylinders. Its installation is small. Our factory has advanced hydraulic equipment, including a vertical and horizontal machining center and medium and large hydraulic cylinders. Thin cylinder production technology is excellent.

Earring Joint Two Stage Telescopic Hydraulic Cylinder Parameter:

Earring Joint Two Stage Telescopic Hydraulic Cylinder Key Features and Benefits:

- Two-Stage Telescopic Design:

- The earring joint two-stage telescopic hydraulic cylinder has a two-stage telescopic design that increases stroke length while maintaining a compact retractable size.

- This design provides greater reach without compromising space constraints, making it ideal for applications where distance and compactness are critical.

- Earring Joint Construction:

- The cylinder is equipped with an earring joint construction, which enables smooth and synchronized movement of the telescopic stages.

- The earring joint mechanism ensures stability, precise alignment, and excellent load-bearing capacity during operation.

- Precise Control:

- The earring joint two-stage telescopic hydraulic cylinder provides excellent expansion and contraction control, allowing precise positioning and efficient operation.

- The precision control mechanism ensures smooth and controlled movement, improving overall productivity and accuracy.

- High Load-Bearing Capacity:

- Designed to handle heavy loads and demanding industrial applications, earring joint two-stage telescopic hydraulic cylinders provide outstanding load-carrying capacity.

- It can lift, push, or pull large amounts of weight, making it a reliable choice for tasks that require a lot of force.

Earring Joint Two Stage Telescopic Hydraulic Cylinder Usage Method:

- Mounting and Installation:

- Determine the appropriate installation location of the earring joint secondary telescopic hydraulic cylinder according to your equipment or mechanical requirements.

- Ensure that the mounting surface is strong, level, and can safely support the weight and load of the cylinder.

- Hydraulic System Connection:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Proper alignment and tight connections prevent leaks and ensure optimum performance.

- Operating the Cylinder:

- Activate the hydraulic system and initiate the movement of the secondary telescopic hydraulic cylinder of the earring connector.

- Use a hydraulic control system, such as a valve or lever, to precisely control the extension and contraction of the cylinder for efficient operation.

How Does A One Way Hydraulic Cylinder Work?

A one-way, single-acting hydraulic cylinder operates using a hydraulic system to generate linear motion in one direction. It consists of a cylinder barrel, piston, piston rod, and hydraulic fluid. Here’s how it works:

- Hydraulic Fluid Supply:

- The hydraulic system supplies pressurized fluid, typically oil, to the cylinder through a hydraulic pump or power source.

- Cylinder Extension:

- When hydraulic fluid is supplied to the cylinder, it enters the cylinder barrel through an inlet port.

- The pressurized fluid pushes against the piston, causing it to move in the desired direction (typically extending the piston rod).

- As the fluid pressure increases, it overcomes the resistance or load on the piston, resulting in the extension of the piston rod.

- Sealing Mechanism:

- The cylinder barrel is sealed to prevent fluid leakage. It typically incorporates seals around the piston and piston rod, such as O-rings or lip seals.

- These seals ensure that the pressurized fluid acts only on one side of the piston, creating a pressure imbalance that drives the piston in the desired direction.

- Return Stroke:

- After the extension stroke, the hydraulic fluid is released or vented from the cylinder.

- The hydraulic system may use gravity, a spring, or an external force to retract the piston and piston rod to their initial positions.

- During the return stroke, the hydraulic fluid flows out of the cylinder through an outlet port.

- Load Support:

- The piston rod of the hydraulic cylinder is often connected to a load or mechanism that requires linear motion or force.

- As the piston extends or retracts, it provides the necessary force to move or support the load.

- Control and Valves:

- To control the extension and retraction of the one-way hydraulic cylinder, the hydraulic system incorporates valves, such as check valves or directional control valves.

- These valves regulate the flow of hydraulic fluid, allowing it to enter and exit the cylinder in the desired direction.

- Application Specifics:

- One-way hydraulic cylinders are commonly used in applications where force or motion is required in only one direction, such as lifting, pushing, or clamping.

- They are often found in hydraulic jacks, hydraulic presses, dump trucks, and various other industrial and mobile equipment.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best compact hydraulic cylinder manufacturers. We can offer comprehensive compact hydraulic cylinder stock. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Aplikasi Silinder Hidraulik: