Hydraulic Direction Cylinder

In qualità di uno dei produttori, fornitori ed esportatori di prodotti meccanici, offriamo cilindri idraulici e molti altri prodotti.

Per maggiori dettagli, contattateci.

Posta:sales@hydraulic-cylinders.net

Produttore fornitore esportatore di cilindri idraulici.

Hydraulic Direction Cylinder

The Hydraulic Direction Cylinder is essential in various hydraulic systems, enabling precise control of fluid flow and direction. This component is critical for applications ranging from industrial machinery to agricultural equipment, where accurate movement is necessary for optimal performance. By understanding the features, usage, and maintenance of hydraulic direction cylinders, you can significantly enhance the efficiency and longevity of your hydraulic systems.

As a key element in modern hydraulic setups, the Hydraulic Direction Cylinder ensures reliable control and precision. Familiarizing yourself with its characteristics, proper usage, and maintenance practices will help keep your hydraulic systems running smoothly and efficiently. Investing in high-quality hydraulic direction cylinders not only boosts performance but also extends their lifespan across a range of applications. Harness the power of precision with hydraulic direction cylinders to elevate your operational capabilities.

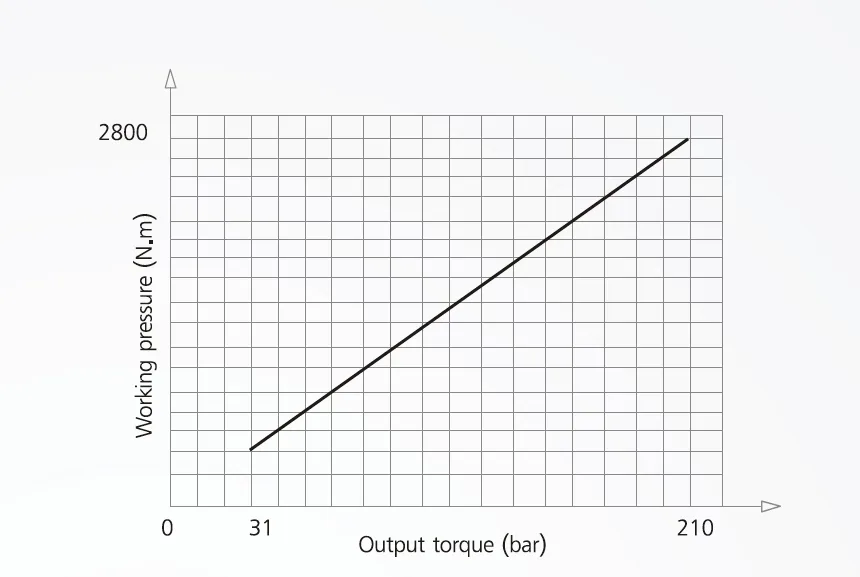

Hydraulic Direction Cylinder Parameter:

Technical parameters

· Rated torque: 2800N.m

·Rated pressure: 21MPa

·Rotation angle: 180

·Displacement: 688c

·Starting pressure: Max 3.1MPa

·Maximum bending torque

for cross over installation: 16900N.m

·Maximum bending torque

for cantilever installation: 7100N.m

·Load in the diameter direction: 2300kg

·Load in the length direction: 1800kg

Key Features of Hydraulic Direction Cylinder:

High Load Capacity

These hydraulic direction cylinders are engineered to withstand significant forces, excelling even under the heaviest loads. Their robust design ensures that they can tackle demanding tasks without compromising performance. Whether lifting, pushing, or pulling, these cylinders deliver reliable power, making them ideal for high-stress applications in various industries.

Durable Construction

Crafted from high-strength materials, hydraulic direction cylinders boast exceptional durability. They resist wear and tear, allowing them to perform consistently in the most challenging environments. This resilience means fewer replacements and repairs, providing peace of mind for operators who rely on their machinery day in and day out.

Corrosion Resistance

Equipped with advanced protective coatings, these cylinders guard against rust and environmental damage. This feature proves invaluable in outdoor applications where exposure to moisture, chemicals, and fluctuating temperatures is common. With corrosion resistance, you can trust that your hydraulic direction cylinders will maintain their integrity and performance over time, regardless of the conditions.

Ingegneria di precisione

Manufactured to exacting standards, hydraulic direction cylinders ensure compatibility with a wide array of hydraulic systems. This precision engineering minimizes the risk of malfunction and maximizes efficiency, allowing for seamless integration into existing setups. Operators can enjoy reliable performance, knowing that these cylinders meet stringent industry specifications.

Applicazione versatile

The versatility of hydraulic direction cylinders makes them a preferred choice across diverse industries, including construction, agriculture, and manufacturing. Their ability to adapt to various tasks—from lifting heavy machinery to controlling agricultural implements—demonstrates their indispensable role in enhancing productivity. No matter the application, these cylinders provide the flexibility and reliability needed to get the job done right.

How Does The Corrosion Resistance Of A Hydraulic Direction Cylinder Enhance Its Performance In Outdoor Environments?

The corrosion resistance of a Hydraulic Direction Cylinder significantly enhances its performance in outdoor environments through several compelling factors:

1. Longevity

Corrosion-resistant coatings act as a shield against rust and deterioration, allowing the cylinder to withstand the elements for years. This durability means fewer replacements, saving both time and money. By investing in these robust cylinders, operators can enjoy peace of mind knowing their equipment will last longer, even in the most demanding conditions.

2. Reliability

In outdoor settings, the risk of environmental damage can jeopardize equipment functionality. Corrosion resistance prevents common failures associated with rust and wear, ensuring that hydraulic cylinders perform consistently. This reliability is crucial for maintaining productivity, as operators can trust that their machinery will run smoothly without unexpected breakdowns.

3. Reduced Maintenance

Less susceptibility to corrosion means fewer maintenance interruptions. Operators can focus on their tasks rather than worrying about frequent repairs. This efficiency not only boosts productivity but also allows maintenance teams to allocate their resources more effectively, enhancing overall operational effectiveness.

4. Safety

Corrosion can lead to dangerous structural weaknesses, posing risks to both operators and equipment. By resisting corrosion, these cylinders maintain their integrity, providing a safer working environment. Operators can work with confidence, knowing that their equipment is built to withstand the rigors of outdoor use without compromising safety.

5. Cost-Effectiveness

Investing in corrosion-resistant hydraulic cylinders translates into long-term savings. The reduced frequency of repairs and replacements enhances the overall cost-effectiveness of the equipment. Operators who prioritize corrosion resistance can enjoy a higher return on investment, as the initial cost is offset by the cylinder’s extended lifespan and reduced maintenance needs.

In summary, the corrosion resistance of Hydraulic Direction Cylinders is not just about protection; it’s about ensuring optimal performance, safety, and cost-efficiency in challenging outdoor environments. This feature makes them an invaluable asset for operators looking to maximize productivity and reliability.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Visitate la nostra fabbrica VR:

Fate un tour della nostra fabbrica VR con quanto segue

Cilindro idraulico Applicazione: