Replacement Of AHC15720 Hydraulic Cylinder

In qualità di uno dei produttori, fornitori ed esportatori di prodotti meccanici, offriamo cilindri idraulici e molti altri prodotti.

Per maggiori dettagli, contattateci.

Posta:sales@hydraulic-cylinders.net

Produttore fornitore esportatore di cilindri idraulici.

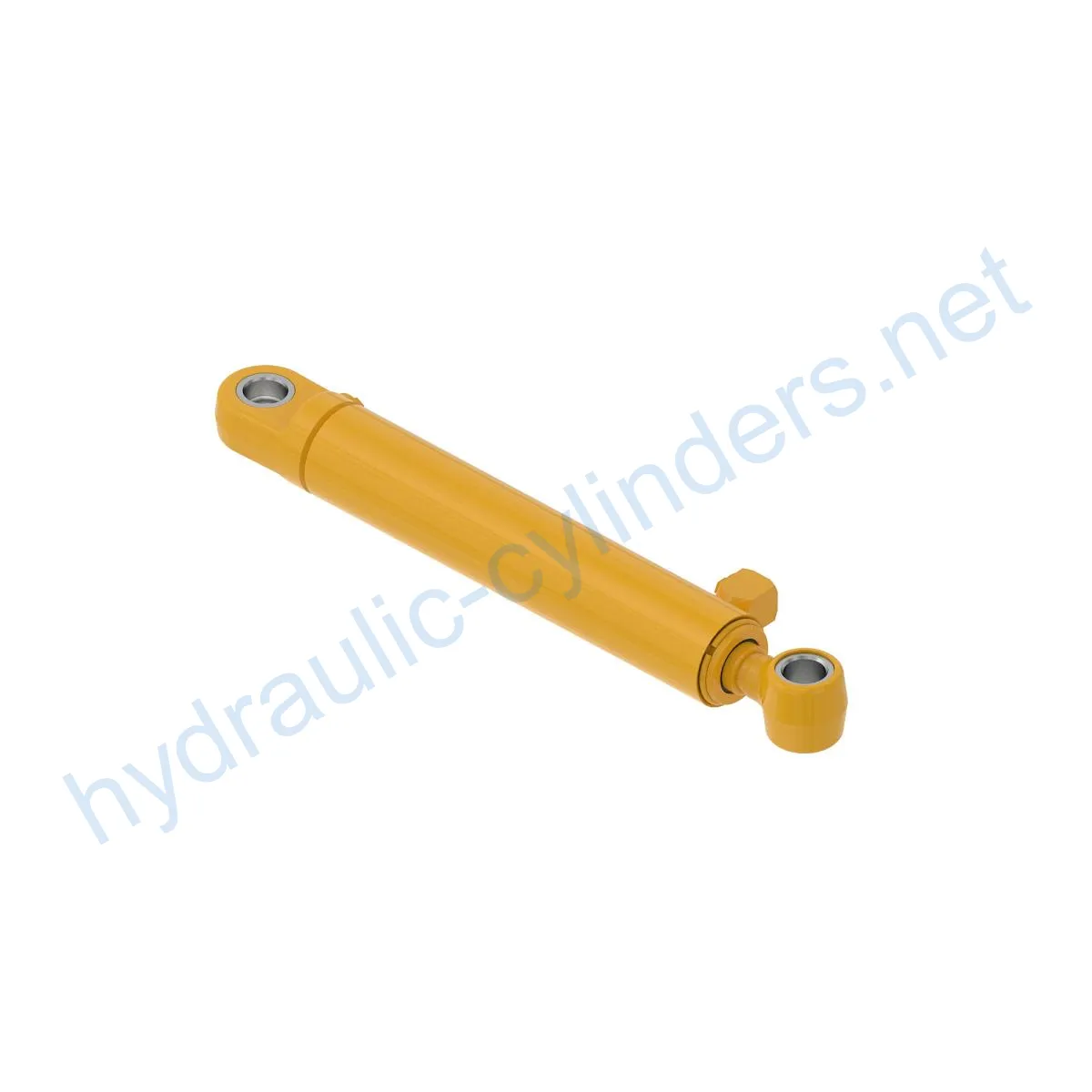

Replacement Of AHC15720 Hydraulic Cylinder

The Replacement Of AHC15720 Hydraulic Cylinder is a vital component used in various industrial machinery and equipment. This hydraulic cylinder plays a crucial role in providing power and control for lifting, pressing, or moving heavy loads. With a weight of 12.42 lb, a height of 2 in, a width of 3.8 in, and a length of 18.8 in, this replacement hydraulic cylinder ensures optimal performance and efficiency.

Product Specifications

- Weight: 12.42 lb

- Height: 2 in

- Width: 3.8 in

- Length: 18.8 in

Product Models

[Insert list of product models here]

Product Features

- Improved Equipment Performance: Replacing damaged or worn-out hydraulic cylinders can restore the normal operational capability of equipment, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders reduces the safety risks caused by cylinder failures, ensuring the safety of both operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, enhancing overall safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it convenient to obtain replacement parts in the market.

Our company specializes in manufacturing replacement hydraulic cylinders. Our products can perfectly replace these hydraulic cylinders, offering reliable performance and durability.

Applications

- Excavators: Hydraulic cylinders in excavator arms or buckets may get damaged due to prolonged use or overload, requiring replacement to restore normal operation.

- Cranes: The hydraulic cylinders in crane boom arms are subjected to frequent lifting and lowering, leading to wear and tear that necessitates regular replacement for safety purposes.

- Tractors: Hydraulic cylinders in front-end loader attachments for tractors may experience leaks or performance degradation due to continuous lifting and tilting operations, requiring replacement.

- Harvesters: Hydraulic cylinders in harvesting machines endure high pressure during the harvesting process, and fatigue damage may occur, requiring timely replacement to maintain efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Any cylinder failure can impact production efficiency and needs immediate replacement.

- Die Casting Machines: In high-pressure and high-temperature environments, hydraulic cylinders in die casting machines may experience performance decline. Regular replacement ensures product quality.

- Mining Equipment: Hydraulic cylinders are used for lifting and moving heavy loads in mining equipment. Due to harsh working conditions, regular inspection and replacement are necessary to avoid equipment failure.

- Bulldozers: Wear on hydraulic cylinders in bulldozer blade arms can lead to a decrease in pushing ability. Timely replacement is necessary to maintain operational efficiency.

Maintenance Tasks

- Regular Inspection: Inspect hydraulic cylinders periodically for any signs of damage, leaks, or wear.

- Proper Lubrication: Ensure proper lubrication of the cylinder components to minimize friction and extend their lifespan.

- Seal Replacement and Calibration Check: Replace worn-out seals and perform calibration checks to maintain optimal performance.

Correct installation, lubrication, and adjustment are essential for the proper functioning of hydraulic cylinders. During installation, provide proper guidance for aligning the cylinder and recommend using suitable installation brackets to secure the cylinder. We offer recommended inspection, repair, and replacement procedures, as well as replacement parts and rebuilding services, to prolong the lifespan of your hydraulic cylinders.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is crucial to prioritize safety measures. Proper handling and adherence to safety guidelines are essential to prevent accidents and injuries. Additionally, considering environmental factors when selecting and using hydraulic cylinders can contribute to sustainable and eco-friendly practices.

Troubleshooting and Common Issues

[Insert troubleshooting and common issues here]

[Provide troubleshooting tips and solutions to help readers effectively diagnose and resolve problems. Suggest preventive measures to minimize potential issues.]

[Insert image here]

Design Considerations and Selection Criteria

[Discuss design considerations such as load-bearing capacity, sealing, durability, safety, and maintainability. Break down each point to provide comprehensive information.]

Sealing and Lubrication

[Discuss the use of various sealing components such as piston seals, rod seals, etc. Highlight the selection of wear-resistant materials like polyurethane and nitrile rubber. Emphasize the importance of proper surface treatment for the cylinder body and threaded ends to enhance wear resistance. Recommend regular lubrication with appropriate hydraulic oil to ensure smooth operation.]

Regular Inspection and Preventive Maintenance

[Discuss the importance of regular inspection and proactive maintenance measures. Break down each point to provide detailed information.]

[Insert installation guide here]

Maintenance Tasks

- Regular Inspection: Inspect hydraulic cylinders periodically for any signs of damage, leaks, or wear.

- Proper Lubrication: Ensure proper lubrication of the cylinder components to minimize friction and extend their lifespan.

- Seal Replacement and Calibration Check: Replace worn-out seals and perform calibration checks to maintain optimal performance.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is crucial to prioritize safety measures. Proper handling and adherence to safety guidelines are essential to prevent accidents and injuries. Additionally, considering environmental factors when selecting and using hydraulic cylinders can contribute to sustainable and eco-friendly practices.

Troubleshooting and Common Issues

[Insert troubleshooting and common issues here]

[Provide troubleshooting tips and solutions to help readers effectively diagnose and resolve problems. Suggest preventive measures to minimize potential issues.]

[Insert image here]

About Our Company

We are a leading manufacturer and wholesaler of replacement hydraulic cylinders in the domestic and international markets. Our company offers a wide range of hydraulic cylinders, providing comprehensive solutions for various industries.

Professionalism

We pride ourselves on our professionalism, ensuring high-quality products and services for our customers.

International Certifications

Our products meet international quality standards and certifications, guaranteeing their reliability and performance.

Customization Services

We offer customization services to meet the specific requirements of our customers, ensuring optimal compatibility and functionality.

State-of-the-Art Production Equipment

Equipped with modern production facilities, we utilize advanced technology to manufacture hydraulic cylinders with precision and efficiency.

After-Sales Services

We provide excellent after-sales services, including technical support and assistance, to ensure customer satisfaction and long-term partnerships.

[Insert company image here]

Author: lyl

Visitate la nostra fabbrica VR:

Fate un tour della nostra fabbrica VR con quanto segue

Cilindro idraulico Applicazione: