Small Excavator Bulldozing Cylinder

In qualità di uno dei produttori, fornitori ed esportatori di prodotti meccanici, offriamo cilindri idraulici e molti altri prodotti.

Per maggiori dettagli, contattateci.

Posta:sales@hydraulic-cylinders.net

Produttore fornitore esportatore di cilindri idraulici.

Small Excavator Bulldozing Cylinder

The small excavator bulldozing cylinder is a high-performance hydraulic component designed to enhance the earthmoving capabilities of small excavators. This cylinder is specifically engineered to deliver exceptional power, versatility, and durability in compact construction machinery.

The small excavator bulldozing cylinder is a powerful and versatile hydraulic component that enhances the earthmoving capabilities of small excavators. This cylinder empowers operators to shape and manipulate terrain efficiently with its compact design, impressive pushing force, precise control, and improved stability. Following the recommended usage methods and maintenance practices, operators can ensure optimal performance and longevity of the small excavator bulldozing cylinder, resulting in increased productivity and the successful completion of various earthmoving projects. Invest in this exceptional hydraulic cylinder to elevate the capabilities of your small excavator and achieve superior results in your earthmoving operations.

Small Excavator Bulldozing Cylinder Key Characteristics:

- Compact Design and Robust Construction

- The Small Excavator Bulldozing Cylinder is meticulously designed to perfectly fit small excavators, ensuring optimal performance and compatibility.

- Built with robust materials and precision engineering, this cylinder can withstand rigorous working conditions, providing long-lasting reliability.

- Impressive Pushing Force and Control

- Despite its small size, the cylinder offers impressive pushing force, allowing efficient and effective bulldozing operations.

- It provides precise control over the dozer blade, enabling operators to maneuver and shape the terrain with accuracy and ease.

- Enhanced Stability and Balance

- The cylinder’s design incorporates features that enhance stability and balance during earthmoving tasks.

- It ensures smooth and controlled blade movements, minimizing the risk of tilting or instability, thereby increasing operator safety.

- Easy Installation and Integration

- The Small Excavator Bulldozing Cylinder is designed for easy installation and integration with small excavators.

- It comes with clear instructions and compatible mounting hardware, facilitating a hassle-free setup process.

Small Excavator Bulldozing Cylinder Parameter:

| Product Name | Small Excavator Bulldozing Cylinder |

| Features: | Control the action of the bulldozer |

| Bore diameter: | 50mm~140mm |

| Rod diameter: | 25mm~80mm Stroke≤250mm |

| Thrust force: | Maximum 453KN |

| Bore diameter: | 140mm/pressure29.4MPa |

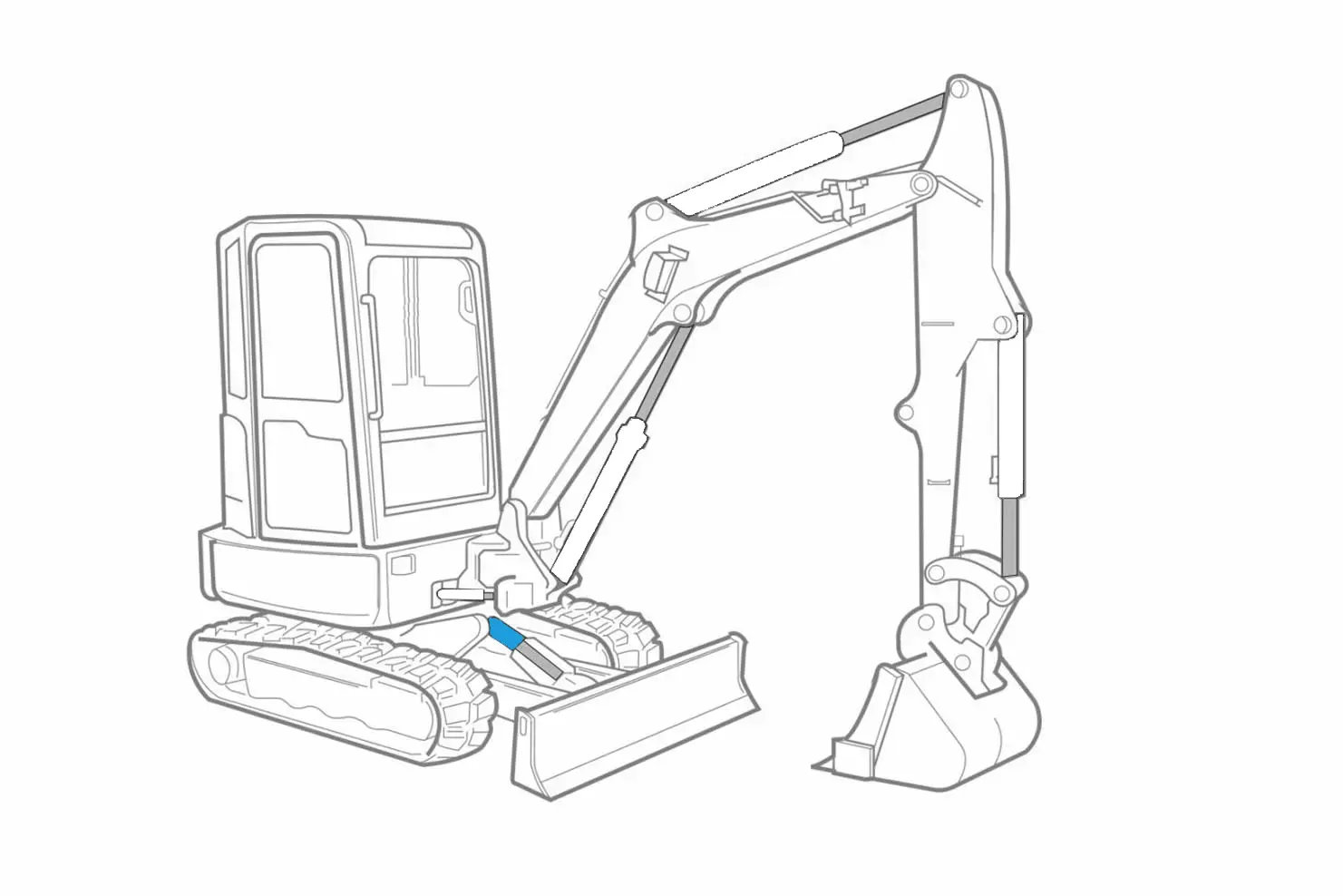

Small Excavator Bulldozing Cylinder Identification Diagram:

Usage Method Of Small Excavator Bulldozing Cylinder:

- Installation and Configuration

- Begin by referring to the manufacturer’s instructions for proper installation of the Small Excavator Bulldozing Cylinder.

- Ensure compatibility and securely attach the cylinder to the excavator’s dozer blade assembly.

- Follow the recommended torque specifications and use appropriate mounting hardware for a secure and reliable connection.

- Operational Considerations

- Familiarize yourself with the controls and operation of the small excavator, including the dozer blade and cylinder.

- Practice operating the excavator and cylinder in a controlled environment before undertaking actual earthmoving tasks.

- Adhere to safety guidelines and operate within the excavator’s load limits to prevent accidents and equipment damage.

- Optimizing Earthmoving Performance

- Utilize the Small Excavator Bulldozing Cylinder’s precise control to optimize earthmoving performance.

- Maintain a steady and controlled speed while pushing material, allowing the cylinder to exert consistent force.

- Adjust the blade angle and height according to the specific terrain and desired outcome, ensuring efficient earthmoving operations.

How To Remove Hydraulic Cylinder From Excavator?

Removing a hydraulic cylinder from an excavator requires careful attention and adherence to proper procedures to ensure safety and prevent damage to the equipment. Here are general steps to guide you through the process:

- Preparation:

- Ensure the excavator is turned off and parked on a level surface.

- Engage the safety lock and secure the boom and arm in a stable position.

- Put on appropriate personal protective equipment, such as gloves and safety glasses.

- Identify the Cylinder:

- Locate the hydraulic cylinder you wish to remove. It may be attached to the boom, arm, or other excavator components.

- Relieve Hydraulic Pressure:

- Before disconnecting any hydraulic lines or fittings, it’s crucial to release the pressure in the system to prevent sudden movements or fluid spray.

- Start by locating your excavator model’s pressure relief valve or pressure release procedure.

- Follow the manufacturer’s guidelines to depressurize the hydraulic system properly.

- Disconnect Hydraulic Lines:

- Identify the hydraulic lines connected to the cylinder. These lines carry hydraulic fluid to and from the cylinder.

- Use appropriate wrenches or fittings to loosen and disconnect the hydraulic lines from the cylinder.

- Place a container or absorbent material beneath the disconnected lines to catch residual hydraulic fluid.

- Remove Mounting Hardware:

- Locate the mounting points of the cylinder. These may be bolts or pins securing the cylinder to the excavator’s structure.

- Use the appropriate tools to remove the mounting hardware depending on the specific design.

- Ensure proper support for the cylinder during removal to prevent it from falling or causing damage.

- Detach the Cylinder:

- Carefully slide or maneuver the cylinder out of its mounting position. If it’s tightly fitted, you may need to gently tap it with a rubber mallet or use a hydraulic cylinder puller for assistance.

- Ensure that no other components or structures are obstructing the cylinder’s removal.

- Inspection and Maintenance:

- Once the cylinder is removed, inspect it for any signs of damage, leaks, or wear.

- Clean the cylinder and inspect the rod, seals, and other components for any signs of corrosion, scoring, or excessive wear.

- Perform any necessary maintenance or repairs before reinstalling the cylinder.

- Reinstallation or Replacement:

- To reinstall the hydraulic cylinder, follow the reverse steps of the removal process, ensuring proper alignment and torque specifications.

- If the cylinder is being replaced, carefully install the new cylinder according to the manufacturer’s instructions and guidelines.

Capacità e capacità della fabbrica:

(1) Montaggio

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Lavorazione

L'officina di lavorazione è dotata di un centro di tornitura su rotaia inclinata personalizzato, di un centro di lavorazione, di una levigatrice ad alta velocità, di un robot di saldatura e di altre attrezzature correlate, in grado di gestire la lavorazione di tubi cilindrici con un diametro interno massimo di 400 mm e una lunghezza massima di 6 metri.

(3) Saldatura

(4) Verniciatura e rivestimento

Con linee automatiche di verniciatura a base d'acqua a cilindro di piccole e medie dimensioni, per realizzare il carico e lo scarico automatico con robot e la spruzzatura automatica, la capacità di progettazione è di 4000 pezzi per turno;

Disponiamo anche di una linea di produzione semiautomatica di vernici per cilindri di grandi dimensioni alimentata da una catena di potenza, con una capacità di progettazione di 60 casse per turno.

(5) Test

Disponiamo di strutture di ispezione e banchi di prova di prim'ordine per garantire che le prestazioni del cilindro siano conformi ai requisiti.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding riduttori agricoli. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and collaborare con noi!

Visitate la nostra fabbrica VR:

Fate un tour della nostra fabbrica VR con quanto segue

Cilindro idraulico Applicazione: