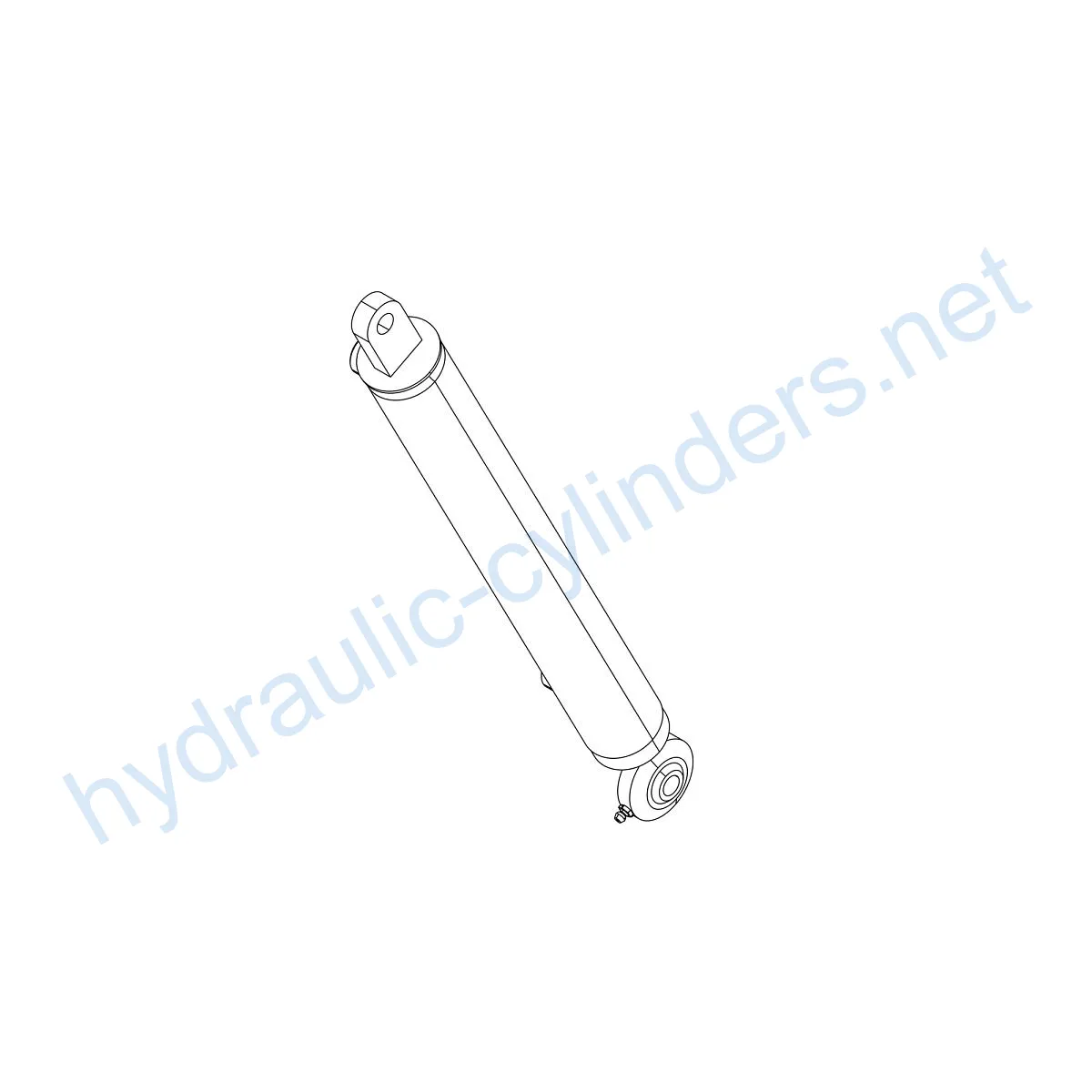

Replacement Of 5HG621554 Hydraulic Cylinder

유압 실린더 제조업체, 공급 업체 및 기계 제품 수출 업체 중 하나로서 유압 실린더 및 기타 여러 제품을 제공합니다.

자세한 내용은 당사에 문의해 주세요.

메일:sales@hydraulic-cylinders.net

유압 실린더 제조업체 공급 업체 수출.

Replacement Of 5HG621554 Hydraulic Cylinder

First, let’s introduce the product and define what this hydraulic cylinder is and its purpose.

Product Specifications and Model

- Weight: 8.03 lb

- Height: 2.5 in

- Width: 3 in

- Length: 20.5 in

Model: D400

Product Features

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the normal operational capability of the equipment, ensuring its performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders reduces safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs typically incorporate better overload protection mechanisms, enhancing safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, facilitating the acquisition of replacement parts in the market.

We can produce this product and provide perfect replacements for these hydraulic cylinders.

Applications of the Hydraulic Cylinder

- Excavators: Hydraulic cylinders on the boom or bucket of excavators may need replacement due to long-term use or overload, to restore normal operation.

- Cranes: Hydraulic cylinders on the lifting arms of cranes are prone to wear during frequent lifting and lowering processes, requiring regular replacement to ensure safety.

- Tractors: Hydraulic cylinders on the front loaders of tractors may experience leaks or performance degradation during constant lifting and tilting operations, necessitating replacement.

- Harvesters: Hydraulic cylinders in harvesting processes endure high pressure, and fatigue can lead to damage, requiring timely replacement to maintain work efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failures can impact production efficiency, necessitating immediate replacement.

- Die Casting Machines: In high-pressure and high-temperature environments, hydraulic cylinders may experience performance degradation. Regular replacement ensures product quality.

- Mining Equipment: Hydraulic cylinders are used for lifting and moving heavy loads in mining equipment. Regular inspection and replacement are necessary to avoid equipment failures.

- Bulldozers: Wear of hydraulic cylinders on the blade of bulldozers can lead to reduced pushing capacity, requiring timely replacement to maintain operational efficiency.

Maintenance Tasks

Regular maintenance tasks for hydraulic cylinders include:

- Periodic inspections

- Proper lubrication

- Seal replacement

- Calibration checks

It is important to emphasize the importance of correct installation, lubrication, and adjustment. Providing proper guidance for aligning the cylinder during installation, recommending the use of suitable installation brackets for securing the cylinder, and suggesting inspection, repair, and replacement procedures are key to extending the lifespan of the hydraulic cylinder.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is crucial to prioritize safety measures. Proper usage of the cylinders and adherence to safety protocols are essential to prevent accidents and ensure a safe working environment.

Fault Diagnosis and Common Problems

Common issues and troubleshooting for hydraulic cylinders:

- Leakage: Check for damaged seals or connections and replace them if necessary.

- Slow Operation: Inspect for low hydraulic fluid levels or clogged filters. Address the issue accordingly.

- Jerky Movements: Check for air bubbles in the hydraulic system and bleed the air out as needed.

- Excessive Noise: Inspect for loose or worn-out components and tighten or replace them accordingly.

Provide troubleshooting tips and solutions to help readers effectively diagnose and solve problems. Additionally, suggest preventive measures to minimize potential issues.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, several design considerations should be taken into account:

- Load-bearing capacity

- Sealing effectiveness

- Durability

- Safety features

- Maintainability

Sealing and Lubrication

Hydraulic cylinders utilize various seals, such as piston seals and rod seals, made of wear-resistant materials such as polyurethane and nitrile rubber. The cylinder body and threaded ends undergo meticulous surface treatment to enhance wear resistance. Regular lubrication with appropriate hydraulic oil is necessary to ensure smooth operation.

Regular Inspection and Preventive Maintenance

It is crucial to perform regular inspections and preventive maintenance. Proper installation, lubrication, and adjustment are vital. Providing guidance for aligning the cylinder correctly during installation, recommending the use of suitable installation brackets to secure the cylinder, and offering inspection, repair, and replacement procedures are essential. Additionally, providing replacement parts and rebuilding services can enhance the longevity of the hydraulic cylinder.

Installation Guide

Proper installation of the hydraulic cylinder is essential for optimal performance. Follow these guidelines:

- Ensure the cylinder is aligned correctly with the equipment.

- Use appropriate installation brackets to secure the cylinder in place.

- Follow recommended inspection, repair, and replacement procedures.

About Our Company

We are a manufacturer of replacement hydraulic cylinders and one of the leading manufacturers and wholesale distributors in the domestic and international markets.

Key aspects of our company:

- Professionalism

- International certifications

- Customization services

- State-of-the-art production equipment

- After-sales service

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: