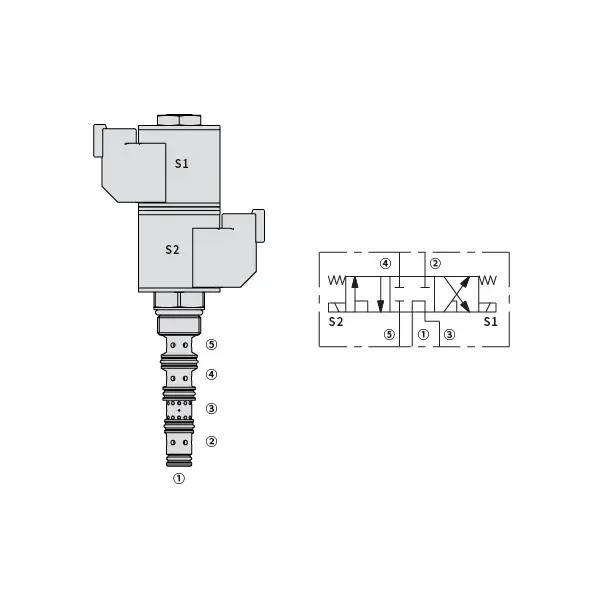

35SD08-58C Solenoid Directional Valve

Являясь одним из производителей, поставщиков и экспортеров механической продукции, мы предлагаем гидравлические цилиндры и многие другие изделия.

Пожалуйста, свяжитесь с нами для получения подробной информации.

Почта:sales@hydraulic-cylinders.net

Производитель поставщик экспортер гидроцилиндров.

35SD08-58C Solenoid Directional Valve

The 35SD08-58C Solenoid Directional Valve is a cutting-edge component designed to revolutionize fluid control systems in various industrial applications. With its advanced features, precise operation, and superior performance, this solenoid valve offers unparalleled precision and efficiency in managing fluid flow. Whether in manufacturing, automation, or process control, the 35SD08-58C Solenoid Directional Valve delivers exceptional functionality and reliability, making it an indispensable tool for optimizing operations and maximizing productivity.

The 35SD08-58C Solenoid Directional Valve is a game-changing component that offers precision and efficiency in fluid control systems across various industries. With its high-quality construction, precise fluid control, versatility, and compact design, this solenoid valve delivers exceptional performance, ensuring optimal operations and enhanced productivity. Incorporate the 35SD08-58C Solenoid Directional Valve into your fluid control systems to unleash precision, efficiency, and reliability, giving your industrial processes the competitive edge they need. Invest in this advanced solenoid valve to elevate your fluid control capabilities and achieve success in your industry.

35SD08-58C Solenoid Directional Valve Characteristics:

- High-Quality Construction: The 35SD08-58C Solenoid Directional Valve is built to withstand the rigorous demands of industrial environments. Crafted with high-quality materials and meticulous engineering, this valve ensures durability and longevity, allowing for reliable performance under challenging conditions.

- Precise Fluid Control: This solenoid valve boasts precise control over fluid flow, enabling accurate regulation and efficient management of liquids or gases. Its responsive solenoid mechanism facilitates rapid and reliable switching between different flow paths, ensuring precise control and minimizing flow disruptions.

- Versatility and Adaptability: The 35SD08-58C Solenoid Directional Valve offers versatile functionality, making it suitable for a wide range of applications. Whether it’s directional control, on/off switching, or pressure regulation, this valve can be tailored to meet specific system requirements, providing flexibility and adaptability in fluid control systems.

- Compact and Space-Efficient Design: With its compact design, the 35SD08-58C Solenoid Directional Valve optimizes space utilization in industrial setups. This space-saving feature allows for efficient system design and installation, ensuring maximum utilization of available resources.

35SD08-58C Solenoid Directional Valve Parameter:

| Rated pressure | 241 bar (3500 psi) | |

| Peak flow | 56.8 L/min (15 gpm) ; See performance chart | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 18/16/13, and level 15/13/11 is recommended to prolong the service life | |

| Internal Leakage | ≤ 0.15 mL/min (3 drops /min) @241 bar | |

| Cavity | VC10-2 | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 241 bar | |

35SD08-58C Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Efficient wet-armature construction

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Industry common cavity

• Hardened parts for long life and low leakage

Usage Method Of 35SD08-58C Solenoid Directional Valve:

- Installation: Follow the manufacturer’s instructions for proper installation of the 35SD08-58C Solenoid Directional Valve. Ensure correct alignment and connection to the fluid control system, using appropriate fittings and seals to maintain a leak-free operation.

- Electrical Connections: Connect the solenoid valve to the power supply according to the specified voltage and electrical requirements. Ensure proper wiring and insulation to guarantee safe and reliable electrical operation.

- Fluid Flow Direction: Determine the desired direction of fluid flow based on your application requirements. The 35SD08-58C Solenoid Directional Valve provides various ports and positions for inlet, outlet, and exhaust, allowing for flexible configuration. Consult the product documentation for the correct port connections.

- Control Signal: Connect the control signal, whether electrical or pneumatic, to the solenoid valve to activate its switching mechanism. Ensure that the control signal is compatible with the valve’s specifications and operating parameters.

How To Change Cartridge In Kohler Shower Valve?

Changing the cartridge in a Kohler shower valve is a relatively straightforward process. Here’s a step-by-step guide on how to replace the cartridge:

- Gather the necessary tools and materials: You’ll need an adjustable wrench, screwdriver, plumber’s grease, and a replacement cartridge specific to your Kohler shower valve model. Make sure to turn off the water supply to the shower before starting the process.

- Remove the handle: Locate the screw that secures the handle in place. It is typically located underneath a decorative cap or cover. Use a screwdriver to remove the screw, then carefully pull off the handle.

- Remove the trim plate: The trim plate is the decorative cover surrounding the valve. Use a screwdriver to remove the screws holding the plate in place. Once the screws are removed, gently pull the trim plate away from the wall to expose the valve assembly.

- Remove the retaining clip: Look for a small retaining clip that holds the cartridge in place. Use a pair of pliers or an adjustable wrench to carefully remove the clip by pulling it straight out.

- Remove the old cartridge: With the retaining clip removed, you can now pull out the old cartridge. Grasp the cartridge firmly and pull it straight out of the valve body. If it’s stuck, you can use a cartridge puller tool for assistance.

- Install the new cartridge: Take the replacement cartridge and align it with the valve body, ensuring that it fits securely. Push the cartridge into place until it is fully seated in the valve body.

- Reassemble the valve: Once the new cartridge is installed, reattach the retaining clip to secure it in place. Make sure the clip is properly aligned and engages with the cartridge.

- Reinstall the trim plate and handle: Place the trim plate back over the valve assembly and secure it with the screws. Then, reattach the handle by aligning it with the valve stem and tightening the screw.

- Turn on the water supply: After completing the cartridge replacement, turn on the water supply to the shower. Check for any leaks around the valve and handle. If you notice any leaks, tighten the connections or consult a professional plumber for assistance.

Возможности и мощности завода:

(1) Сборка

Мы располагаем первоклассной независимой сборочной платформой для проведения исследований и разработок. Цех по производству гидравлических цилиндров имеет четыре полуавтоматические линии сборки подъемных цилиндров и одну автоматическую линию сборки цилиндров наклона с проектной годовой производственной мощностью 1 млн. штук. Цех по производству специальных цилиндров оснащен полуавтоматической очистной сборочной системой различных спецификаций с проектной годовой производственной мощностью 200 тыс. штук и оснащен известным обрабатывающим оборудованием с ЧПУ, обрабатывающим центром, высокоточным специальным оборудованием для обработки цилиндров, роботом-сварщиком, автоматической очистной машиной, автоматической сборочной машиной цилиндров и автоматической покрасочной производственной линией. Существующее критически важное оборудование насчитывает более 300 комплектов (комплектов). Оптимальное распределение и эффективное использование ресурсов оборудования позволяет обеспечить требования к точности изделий и удовлетворить потребности в высоком качестве продукции.

(2) Механическая обработка

Цех оснащен специализированным токарным центром с наклонной направляющей, обрабатывающим центром, высокоскоростным хонинговальным станком, сварочным роботом и другим сопутствующим оборудованием, которое позволяет обрабатывать цилиндрические трубы с максимальным внутренним диаметром 400 мм и максимальной длиной 6 м.

(3) Сварка

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: