Forklift

Hydraulic Cylinder

Hydraulic Cylinder For Forklift Lift

A hydraulic cylinder for forklifts is a vital component of the forklift’s hydraulic system, essential for efficiently lifting and lowering the mast and forks. This robust mechanical device converts hydraulic fluid pressure into linear force, enabling forklifts to handle heavy loads with ease. When hydraulic fluid enters the cylinder, it pushes the piston to create the necessary force for raising or lowering loads.

This hydraulic lifting process is crucial for ensuring smooth and controlled operations during material handling tasks in warehouses, construction sites, and other heavy-duty environments. By utilizing high-quality hydraulic cylinders, businesses can enhance forklift performance, improve safety, and increase productivity in their operations.

Types of Forklift Hydraulic Cylinders

Small Forklift Hydraulic Cylinder

Large Forklift Hydraulic Cylinder

Storage And Handling Vehicle Hydraulic Cylinder

Storage And Handling Vehicle Hydraulic Cylinder

Hydraulic Cylinders Of Pallet Stacker Truck

Hydraulic Cylinders Of Pallet Stacker Truck

Forward Moving Forklift Hydraulic Cylinder

Forward Moving Forklift Hydraulic Cylinder

Hydraulic Cylinder Production Area

We are a leading manufacturer specializing in hydraulic cylinders and hydraulic systems, dedicated to delivering high-tech solutions. Our company primarily serves OEMs in industries such as construction machinery, aerial work platforms, sanitation vehicles, wind power, and agricultural machinery. We offer a versatile range of hydraulic cylinders with inner diameters ranging from +20 to 500 mm, boasting an impressive annual design capacity of 1.2 million units.

Our state-of-the-art facilities include a provincial research institute, a high-tech R&D center, and a specialized hydraulic product testing laboratory. We utilize advanced equipment such as dedicated turning centers, high-speed cutting and polishing machines, automatic processing and welding systems, automatic cleaning and assembly lines, fully automated flexible painting lines, and intelligent logistics assembly lines. This comprehensive production and testing capability enables us to maintain a strong technological development capacity, ensuring our manufacturing processes and product quality meet advanced national standards.

Visit our VR hydraulic cylinder factory:

Production and Processing Workshop

Loading and Unloading Robots For Paint Lines

Product Testing Center

Cylinder Composite Machining Center

Automatic Cylinder Assembly Machine

With a robust quality assurance system in place, we have achieved ISO 9001 certification for quality management, as well as ISO 45001 for occupational health and safety, and ISO 14001 for environmental management. Our efficient, standardized processes and self-developed high-end equipment guarantee that our hydraulic cylinders are durable, pressure-resistant, leak-proof, and highly stable, with performance metrics that meet international benchmarks.

The “Huachang” series hydraulic cylinders are designed with a focus on structural integrity, reliable performance, and ease of maintenance. Their diverse structural forms allow for tailored solutions to meet specific customer needs. Coupled with our digital production management system, we respond quickly and effectively to customer requirements, ensuring that we exceed your expectations.

Choose us for high-quality hydraulic solutions that enhance your machinery’s performance and reliability.

Cylinder Assembly Line

Special Cylinder Testing Machine

Cylinder Inspection Area

Multi Station Welding Robot

Warehouse

Forklift Hydraulic Cylinders For Sale

Отображение 1–12 из 17

-

Гидравлический цилиндр регулировки расстояния между вилочными погрузчиками

-

Forklift Lift Cylinder Main Lift Cylinder On Forklift

-

Гидравлический цилиндр короткого подъема вилочного погрузчика

-

Гидравлический цилиндр рулевого управления вилочного погрузчика

-

Гидравлический цилиндр наклона вилочного погрузчика

-

HCYY11112000 Forklift Lifting Cylinder

-

HCYY11112001 Forklift Tilt Cylinder

-

HCYY11112002 Forklift Steering Cylinder

-

Left and Right Forward Extension Cylinders for Forward Moving Forklift

-

Lift Hydraulic Cylinders for Forward Moving Forklift

-

Lift Hydraulic Cylinders For Large Forklift

-

Lifting Hydraulic Cylinders for Storage and Handling Vehicles

How to Remove a Hydraulic Cylinder from a Forklift?

1. Identify the Cylinder Type

Determine whether you’re working with a forklift main lift cylinder, tilt cylinder forklift, or another type like a power steering cylinder. The forklift lift cylinder is typically a single-acting cylinder that raises the mast, while the forklift tilt cylinder is double-acting, controlling forward and backward mast tilt. Trace the hydraulic lines to locate the cylinder, which is often a large, cylindrical component connected to the lifting or tilting mechanism.

2. Relieve Hydraulic Pressure

To avoid injury or damage, relieve pressure in the hydraulic system:

- Lower the forks to the ground.

- Turn off the forklift and disconnect the hydraulic lines from the forklift hydraulic lift cylinder or tilt cylinder forklift.

- Drain the hydraulic fluid into a container to prevent spills. Ensure proper disposal of the fluid per environmental regulations.

3. Secure the Mast

For a forklift main lift cylinder, secure the mast to prevent it from moving:

- Extend the forks as high as possible and chain the mast to a stable anchor point.

- Lower the forks slightly to slacken the chains and hydraulic lines, ensuring the mast is safely supported.

4. Disconnect the Hydraulic Lines

Carefully disconnect the hydraulic lines from the forklift hydraulic cylinder:

- Use a wrench to loosen the fittings, turning counterclockwise.

- Place a drain pan under the lines to catch any residual fluid.

- Cap the lines to prevent contamination of the hydraulic system.

5. Remove Mounting Hardware

Locate the bolts, pins, or clips securing the forklift lift cylinder or forklift tilt cylinder:

- Use a wrench or socket set to remove bolts, turning counterclockwise to avoid stripping.

- If a roll pin or retaining clip is present, carefully remove it with a punch or pliers.

- For forklift hydraulic rams, check for additional retention hardware at the top or bottom of the cylinder.

6. Detach the Cylinder

Gently detach the forklift hydraulic cylinder from its mounting points:

- Tap the cylinder lightly with a soft-faced hammer to loosen it.

- Use a pry bar cautiously if needed, avoiding damage to the cylinder or forklift frame.

- For complex setups, consider using a specialized hydraulic cylinder removal tool for your forklift model.

7. Lower and Remove the Cylinder

Once detached, compress the cylinder by pushing the rod down (if necessary):

- For a forklift main lift cylinder, the shaft may need to be lowered manually.

- Lift the cylinder out of the mast with assistance, as forklift hydraulic rams can be heavy.

- Place the cylinder in a clean workspace for inspection or repair.

What Are The Common Causes And Solutions For Forklift Lift Cylinder Leaking?

Causes:

1. Worn Seals

Explanation: Over time, seals can wear out due to constant exposure to hydraulic fluid and varying temperatures. This degradation can lead to leaks.

Impact: Worn seals not only cause fluid loss but can also compromise the entire hydraulic system, leading to reduced lifting capacity and efficiency.

Solution: Regularly inspect seals and replace them as part of routine maintenance. Use high-quality replacement seals that are compatible with your hydraulic fluid to ensure long-lasting performance.

2. Damaged Cylinder Rod

Explanation: Scratches, dents, or corrosion on the cylinder rod can prevent a proper seal, allowing hydraulic fluid to escape.

Impact: A damaged rod can lead to significant leaks, decreased lifting power, and increased wear on other components.

Solution: Keep the cylinder rod clean and inspect it frequently. If damage is found, consider polishing the rod or replacing it with a high-quality rod designed for durability.

3. Improper Installation

Explanation: If the hydraulic cylinder is not installed correctly, it can lead to misalignment, resulting in undue stress on seals and components.

Impact: Misalignment can cause premature wear and leaks, ultimately affecting the overall operation of the forklift.

Solution: Ensure that cylinders are installed by trained professionals who can guarantee proper alignment and secure connections. Always refer to the manufacturer’s guidelines during installation.

4. Contamination

Explanation: Dirt, debris, or moisture entering the hydraulic system can damage seals and other critical components.

Impact: Contamination can lead to leaks and system failures, increasing repair costs and downtime.

Solution: Implement regular cleaning and maintenance protocols for your hydraulic system. Use filters to prevent contaminants from entering the system and perform routine fluid changes to maintain hydraulic fluid quality.

5. Excessive Pressure

Explanation: Operating the forklift beyond the rated pressure of the hydraulic cylinder can cause leaks and damage.

Impact: This not only leads to leaks but can also result in catastrophic failures, putting operators at risk.

Solution: Monitor hydraulic pressure regularly and ensure that your forklift operates within its specified limits. Consider installing pressure relief valves to prevent excessive pressure buildup.

How Forklift Hydraulic Cylinders Work?

Forklift hydraulic cylinders are the backbone of a forklift’s ability to lift, tilt, and maneuver heavy loads with precision and power. These robust components convert hydraulic fluid pressure into linear mechanical force, enabling smooth and controlled movements of the forklift’s mast, forks, and attachments.

Understanding how they work can help you appreciate their critical role in improving efficiency and safety in warehouses, construction sites, and other material handling environments. Below, we explain the mechanics in simple terms, covering the key components, fluid dynamics, and piston movement, with visuals to bring the concepts to life.

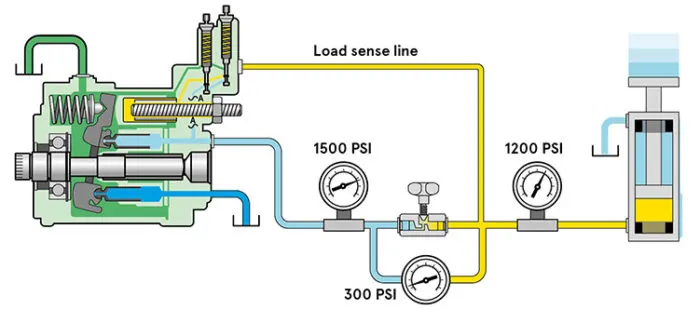

The Basics of Hydraulic Cylinder Mechanics

The cylinder operates based on Pascal’s Principle, which states that pressure applied to a confined fluid is transmitted equally in all directions…

A hydraulic pump, driven by the forklift’s engine or electric motor, forces hydraulic fluid into the cylinder through a hose or port. The fluid enters one side of the cylinder, either the cap end (to extend the piston) or the rod end (to retract it).

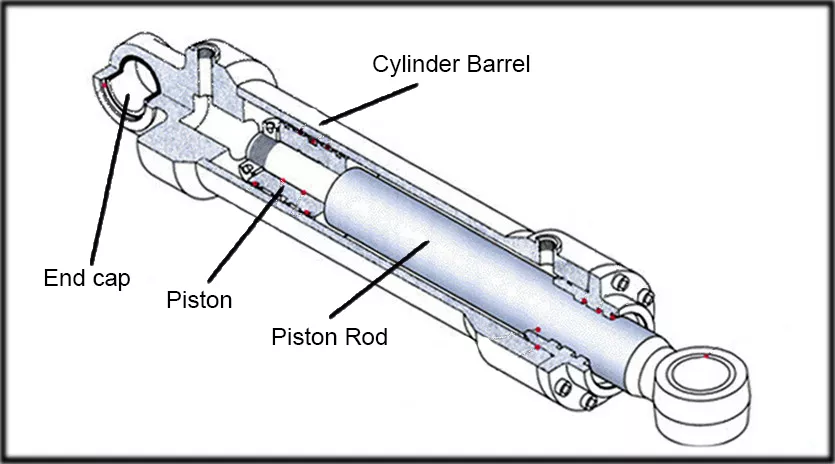

Inside the cylinder is a piston, a metal disc that divides the cylinder into two chambers. When pressurized fluid enters the cap end, it pushes the piston toward the rod end, extending the piston rod—a sturdy metal shaft connected to the piston.

The piston rod’s extension transfers force to the forklift’s components. The force generated depends on the fluid pressure and the piston’s surface area (Force = Pressure × Area).

How Forklift Hydraulic Cylinders Work?

1. Check Hydraulic Fluid Levels Regularly

Hydraulic fluid is the lifeblood of your forklift’s hydraulic system, transmitting pressure to drive the cylinder’s piston. Low or contaminated fluid can cause sluggish performance, overheating, or damage to internal components.

- How to Check: Locate the hydraulic fluid reservoir (usually near the forklift’s pump or engine). Use the dipstick or sight glass to verify the fluid level is within the recommended range. Check weekly or every 100 operating hours.

- What to Look For: Ensure the fluid is clean, free of debris, and not discolored (milky or dark fluid indicates contamination).

- Action: Top off with the manufacturer-recommended hydraulic fluid (e.g., ISO 32 or 46). If contaminated, drain and replace the fluid, and inspect the reservoir filter for clogs.

- Pro Tip: Always use fluid compatible with your cylinder’s seals to prevent degradation. Consult your forklift’s manual or contact Huachang for guidance.

2. Inspect Seals for Wear or Leaks

Seals are critical to preventing hydraulic fluid leaks and keeping contaminants out of the cylinder. Over time, seals can wear out due to pressure, temperature changes, or abrasion, leading to leaks that compromise performance.

-

How to Inspect: Visually examine the piston rod and cylinder ends for signs of fluid leakage, such as wet spots or drips. Check seals every 500 operating hours or during routine maintenance.

-

What to Look For: Cracked, brittle, or deformed seals, or fluid residue around the rod or end caps. Minor leaks may appear as a thin film, while major leaks cause puddles.

-

Action: Replace worn or damaged seals immediately with high-quality, compatible replacements. Clean the area to remove debris before installing new seals.

-

Pro Tip: Use seals designed for your cylinder’s operating conditions (e.g., high-pressure or high-temperature environments). Huachang offers durable seals for all our forklift hydraulic cylinders.

3. Clean the Piston Rod to Prevent Damage

Dirt, dust, or debris on the piston rod can damage seals and cause leaks by scratching the rod’s surface or wearing out the seals during movement.

-

How to Clean: Wipe the piston rod with a clean, lint-free cloth after each shift or when operating in dusty environments (e.g., construction sites). Use a mild solvent if necessary, but avoid abrasive materials.

-

What to Look For: Accumulated dirt, grease, or small particles on the rod. Inspect for scratches or dents that could compromise the seal.

-

Action: Clean thoroughly and inspect the rod for damage. If scratches or corrosion are present, consider polishing the rod or replacing it to prevent further issues.

-

Pro Tip: Apply a thin layer of hydraulic fluid to the rod after cleaning to reduce friction and protect against corrosion.

4. Monitor Hydraulic Pressure to Avoid Overloading

Operating the forklift beyond the hydraulic cylinder’s rated pressure can cause seals to fail, rods to bend, or the cylinder to crack, leading to leaks or catastrophic failure.

-

How to Monitor: Check the forklift’s pressure gauge (if equipped) during operation to ensure it stays within the cylinder’s specified range (e.g., 200–300 bar for most forklift cylinders). Monitor monthly or after heavy use.

-

What to Look For: Spikes in pressure or readings above the cylinder’s maximum rating. Listen for unusual noises (e.g., hissing or grinding) that may indicate pressure issues.

-

Action: Adjust the hydraulic system’s pressure relief valve if necessary, or consult a technician. Avoid lifting loads heavier than the forklift’s rated capacity.

-

Pro Tip: Install a pressure relief valve if your system lacks one to prevent over-pressurization. Huachang’s cylinders are tested to meet international pressure standards for safety.

5. Schedule Regular Professional Inspections

While daily and weekly checks handle basic maintenance, professional inspections catch issues that may go unnoticed, such as internal wear or misalignment.

-

How to Schedule: Arrange for a certified technician to inspect the hydraulic system every 1,000 operating hours or annually, whichever comes first.

-

What to Look For: Internal corrosion, worn bearings, or misalignment between the cylinder and forklift components. Technicians may use diagnostic tools to assess performance.

-

Action: Address any identified issues promptly, such as replacing worn parts or realigning the cylinder. Use genuine Huachang parts for compatibility and durability.

-

Pro Tip: Keep a maintenance log to track inspections, fluid changes, and repairs, ensuring compliance with OSHA or local safety regulations.

Why Maintenance Matters

Regular maintenance of forklift hydraulic cylinders offers several benefits:

Prevents Downtime

Catching issues early reduces unexpected breakdowns, keeping your operations running smoothly.

Extends Lifespan

Proper care can extend cylinder life by years, saving on replacement costs.

Enhances Safety

Well-maintained cylinders reduce the risk of leaks or failures that could endanger operators.

Boosts Efficiency

Clean, properly lubricated cylinders operate more smoothly, improving forklift performance.

FAQs About Forklift Hydraulic Cylinders

Forklift hydraulic cylinders typically last 5–10 years or 10,000–20,000 operating hours, depending on usage, maintenance, and operating conditions. Regular maintenance, such as checking fluid levels and inspecting seals, can extend their lifespan significantly.

Harsh environments (e.g., dusty construction sites) or overloading may shorten their life. Huachang’s high-quality cylinders, built with durable materials and ISO-certified processes, are designed to maximize longevity even in demanding applications.

Replacing a forklift hydraulic cylinder is possible for those with mechanical expertise, but it’s not recommended without proper training. The process involves:

- Draining hydraulic fluid

- Disconnecting hoses

- Ensuring precise alignment

For best results, hire a certified technician or contact Huachang’s support team for expert guidance and compatible replacement parts, like our HCYY11112000 Forklift Lifting Cylinder.

Common signs of a failing hydraulic cylinder include:

- Leaks: Visible fluid around the piston rod or end caps

- Sluggish Movement: Slow or jerky lifting/tilting due to low fluid or worn seals

- Unusual Noises: Grinding or hissing sounds indicating pressure issues

- Reduced Power: Inability to lift rated loads

If you notice these symptoms, inspect the cylinder immediately and replace worn parts. Huachang offers durable replacement seals and cylinders to restore performance.

You should perform:

- Basic maintenance weekly (e.g., checking fluid levels, cleaning the piston rod)

- Thorough inspections every 500 operating hours or quarterly

Professional inspections are recommended annually or every 1,000 hours to catch internal wear or misalignment. Follow Huachang’s maintenance tips, like using compatible fluids and seals, to keep your cylinders in top condition.