HP3V Series Axial Piston Variable Displacement Hydraulic Pump

Являясь одним из производителей, поставщиков и экспортеров механической продукции, мы предлагаем гидравлические цилиндры и многие другие изделия.

Пожалуйста, свяжитесь с нами для получения подробной информации.

Почта:sales@hydraulic-cylinders.net

Производитель поставщик экспортер гидроцилиндров.

HP3V Series Axial Piston Variable Displacement Hydraulic Pump

The HP3V series axial piston variable displacement hydraulic pump is a game-changer in hydraulic systems. This pump is designed with precision engineering and cutting-edge technology and delivers superior efficiency and performance, making it an indispensable component for various industrial applications. This comprehensive article will explore the key characteristics, usage methods, and maintenance guidelines for the HP3V axial piston variable displacement hydraulic pump.

The HP3V series axial piston variable displacement hydraulic pump is a powerhouse that delivers unmatched efficiency and performance in hydraulic systems. With its variable displacement technology, compact design, and quiet operation, this pump is a reliable and precise solution for various industrial applications. By following the recommended usage methods and adhering to regular maintenance practices, the HP3V series pump will continue to provide exceptional performance, contributing to the success of various hydraulic systems. Embrace the power of efficiency and performance with the HP3V series axial piston variable displacement hydraulic pump and unlock the full potential of your hydraulic system.

HP3V Series Axial Piston Variable Displacement Hydraulic Pump Key Characteristics:

- Variable Displacement Technology: The HP3V series pump has advanced variable displacement technology, allowing it to adjust the output volume based on system requirements. This feature maximizes energy efficiency, reduces heat generation, and optimizes overall system performance.

- Unparalleled Efficiency: The HP3V series pump achieves exceptional efficiency with its innovative axial piston design. It provides precise hydraulic power, ensuring smooth operation and enabling the handling of high-pressure applications with ease.

- Compact Design: The pump’s compact design optimizes space utilization in hydraulic systems. Its small footprint enables easy integration, even in tight spaces, without compromising performance or functionality.

- Quiet Operation: Noise reduction features incorporated into the HP3V series pump ensure quiet operation in diverse industrial environments. This characteristic is precious in applications that require low noise levels, promoting a comfortable and productive work environment.

HP3V Series Axial Piston Variable Displacement Hydraulic Pump Parameter:

| Size | Displacement cc/rev | Pressure bar | Rotation speed r/min | ||

| Rated | Peak | Max for self-priming*1 | Max*2 | ||

| HP3V80 | 80 | 320 | 350 | 2400 | 3000 |

| HP3V140 | 140 | 350 | 400 | 2150 | 2500 |

HP3V Series Axial Piston Variable Displacement Hydraulic Pump Advantages:

• Applied in open circuit medium and high pressure applications

• High continuous pressure

• Good self-priming properties

• High reliability

• High power to weight ratio

• Multiple control methods

• Fast response

• Low pressure pulse

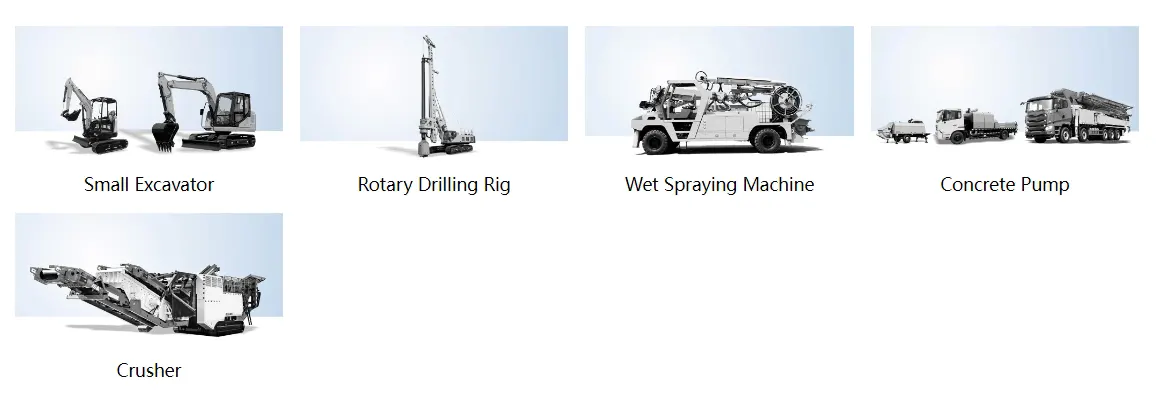

HP3V Series Axial Piston Variable Displacement Hydraulic Pump Application:

Usage Method Of HP3V Series Axial Piston Variable Displacement Hydraulic Pump:

- Pump Installation: Install the HP3V series axial piston variable displacement hydraulic pump in the designated location within the hydraulic system. Refer to the manufacturer’s guidelines and specifications for proper alignment and secure attachment to the system’s structure using suitable mounting brackets or accessories.

- Hydraulic System Integration: Connect the pump to the hydraulic system using compatible hoses, fittings, and valves. Ensure all connections are secure, leak-free, and correctly tightened to guarantee optimal hydraulic performance.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the HP3V series pump. Refer to the manufacturer’s recommendations for the appropriate fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure proper pump operation and longevity.

- Operational Parameters: Familiarize yourself with the pump’s control options and adjust the operating parameters according to the specific requirements of the hydraulic system. Monitor and change the pump’s displacement settings to optimize performance and energy efficiency.

How To Remove Hydraulic Cylinder End Cap?

To remove the end cap of a hydraulic cylinder, follow these steps:

- Prepare for the Task:

- Ensure the hydraulic system is depressurized and disconnected.

- Clean the exterior of the cylinder to prevent debris from entering during the process.

- Place the cylinder on a stable work surface and secure it using clamps or a vise.

- Identify Retaining Mechanisms:

- Inspect the cylinder to determine the retaining mechanism used on the end cap. It could be bolts, threaded connections, snap rings, or retaining rings.

- Remove Bolts or Fasteners:

- If the end cap is secured with bolts, use an appropriate wrench or socket to loosen and remove them.

- Ensure you have suitable access to all the bolts and remove them evenly, avoiding any damage to the cylinder or end cap.

- Loosen Threaded Connections:

- For threaded connections, use a wrench or spanner to loosen the relationship between the end cap and the cylinder body.

- Apply gentle but consistent force in a counterclockwise direction to loosen the threads.

- Once loosened, continue turning the end cap by hand until it can be entirely removed.

- Remove Snap Rings or Retaining Rings:

- If the end cap is secured with snap rings or retaining rings, use snap ring pliers or retaining ring pliers to remove the rings carefully.

- Insert the pliers into the ring’s ends and squeeze the handles to compress the ring, allowing it to be pulled out of its groove.

- Take caution not to damage the cylinder or end cap during this process.

- Separate the End Cap:

- Once all retaining mechanisms are removed, gently tap the end cap with a rubber mallet or a soft-faced hammer to loosen it from the cylinder body.

- Apply even force around the circumference of the end cap to prevent it from binding or becoming stuck.

- Inspect and Clean:

- Once the end cap is removed, inspect the sealing surfaces, O-rings, and internal components for any damage or wear.

- Clean the end cap, cylinder body, and all related components using a lint-free cloth or a suitable solvent to remove any contaminants or debris.

Возможности и мощности завода:

(1) Сборка

Мы располагаем первоклассной независимой сборочной платформой для проведения исследований и разработок. Цех по производству гидравлических цилиндров имеет четыре полуавтоматические линии сборки подъемных цилиндров и одну автоматическую линию сборки цилиндров наклона с проектной годовой производственной мощностью 1 млн. штук. Цех по производству специальных цилиндров оснащен полуавтоматической очистной сборочной системой различных спецификаций с проектной годовой производственной мощностью 200 тыс. штук и оснащен известным обрабатывающим оборудованием с ЧПУ, обрабатывающим центром, высокоточным специальным оборудованием для обработки цилиндров, роботом-сварщиком, автоматической очистной машиной, автоматической сборочной машиной цилиндров и автоматической покрасочной производственной линией. Существующее критически важное оборудование насчитывает более 300 комплектов (комплектов). Оптимальное распределение и эффективное использование ресурсов оборудования позволяет обеспечить требования к точности изделий и удовлетворить потребности в высоком качестве продукции.

(2) Механическая обработка

Цех оснащен специализированным токарным центром с наклонной направляющей, обрабатывающим центром, высокоскоростным хонинговальным станком, сварочным роботом и другим сопутствующим оборудованием, которое позволяет обрабатывать цилиндрические трубы с максимальным внутренним диаметром 400 мм и максимальной длиной 6 м.

(3) Сварка

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: