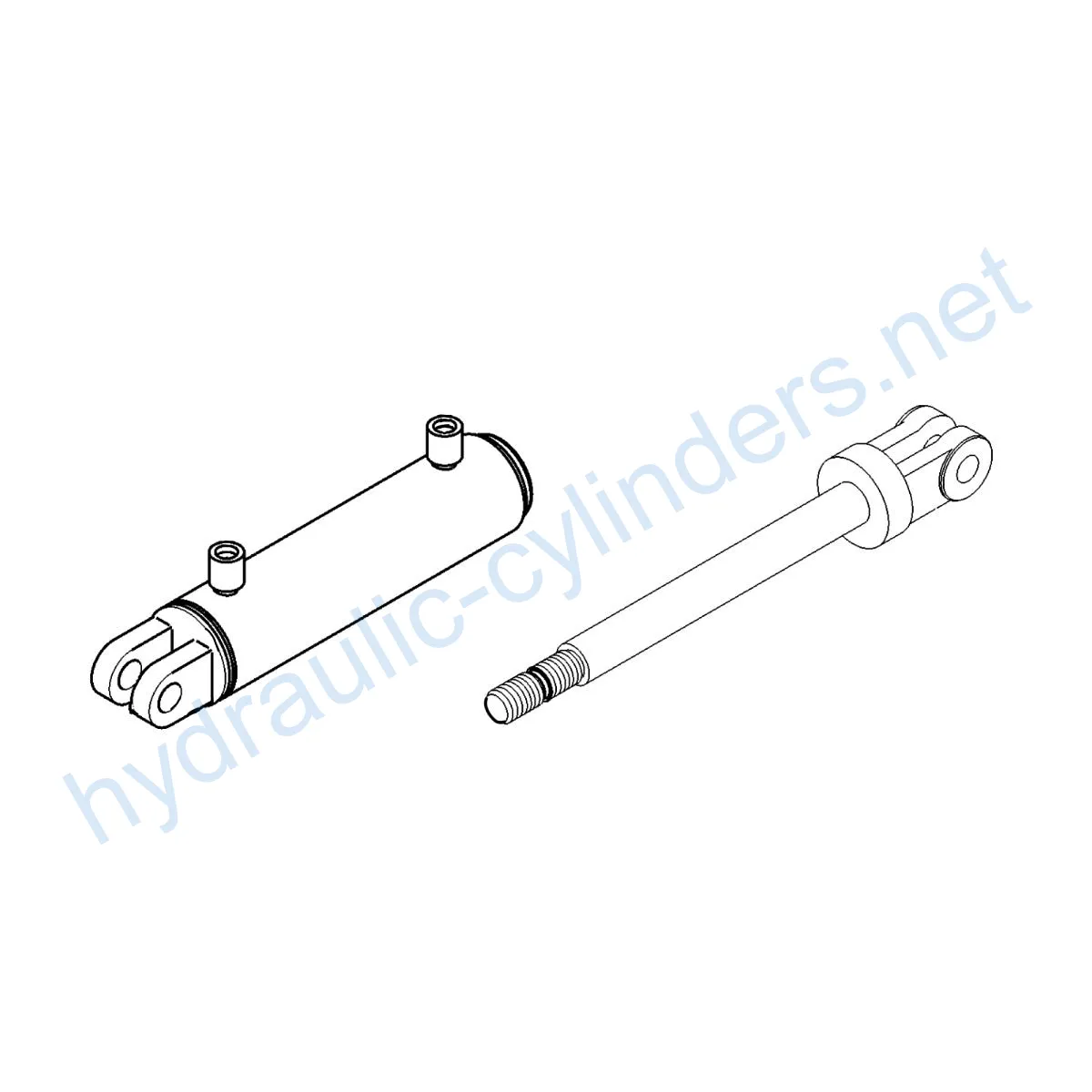

Replacement Of AH210891 Hydraulic Cylinder

Являясь одним из производителей, поставщиков и экспортеров механической продукции, мы предлагаем гидравлические цилиндры и многие другие изделия.

Пожалуйста, свяжитесь с нами для получения подробной информации.

Почта:sales@hydraulic-cylinders.net

Производитель поставщик экспортер гидроцилиндров.

Replacement Of AH210891 Hydraulic Cylinder

First, let’s introduce the product and define what this hydraulic cylinder is and its purpose. The Replacement Of AH210891 Hydraulic Cylinder is a crucial component used in various machinery to convert fluid power into linear mechanical force and motion. It is designed to provide reliable and efficient operation in demanding applications.

Specifications and Model

The Replacement Of AH210891 Hydraulic Cylinder has the following specifications:

- Weight: 19.62 lb

- Height: 5.2 in

- Width: 5.2 in

- Length: 28 in

It is compatible with the 1725NT 9970 model.

Key Features

1. Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the normal operating capabilities of machinery, ensuring optimal performance in various applications.

2. Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

3. Overload Protection: The new cylinder design typically incorporates better overload protection mechanisms, improving overall safety.

4. Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime during maintenance procedures.

5. Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

Our company specializes in manufacturing replacement hydraulic cylinders that perfectly substitute for the originals. We offer a wide range of products to meet different customer needs.

Applications

The Replacement Of AH210891 Hydraulic Cylinder can be used in various applications:

- Excavators: Hydraulic cylinders in excavator arms or buckets may get damaged due to prolonged use or overload and require replacement to restore normal operation.

- Cranes: Hydraulic cylinders in crane boom arms are prone to wear and tear during frequent lifting and lowering processes, necessitating regular replacement to ensure safety.

- Tractors: Front-end loader hydraulic cylinders in tractors can develop leaks or performance issues due to continuous lifting and tilting operations, requiring replacement.

- Harvesters: The hydraulic system in harvesters operates under high pressure, and fatigue can lead to cylinder damage. Timely replacement is essential to maintain work efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failure can significantly impact production efficiency and should be promptly addressed.

These are just a few examples, and the Replacement Of AH210891 Hydraulic Cylinder finds applications in many other industries, such as mining, bulldozers, and die-casting machines.

Maintenance Tasks

Regular maintenance tasks for the Replacement Of AH210891 Hydraulic Cylinder include:

- Periodic Inspection: Regularly inspect the cylinder for any signs of damage, leaks, or abnormal wear.

- Proper Lubrication: Ensure proper lubrication by applying the recommended hydraulic oil at regular intervals.

- Seal Replacement and Calibration Check: Replace worn seals and periodically check the cylinder’s calibration for optimal performance.

Correct installation, lubrication, and adjustment are essential to maximize the lifespan of the hydraulic cylinder. During installation, provide proper guidance on aligning the cylinder and recommend using appropriate mounting brackets to secure it. We also offer inspection, repair, and replacement services to ensure the longevity of the hydraulic cylinder.

Safety Considerations and Environmental Factors

When using the Replacement Of AH210891 Hydraulic Cylinder, it is crucial to follow safety measures to prevent accidents and injuries. Safety precautions should always be a priority when handling hydraulic systems to ensure the well-being of operators and equipment. Additionally, environmental factors must be considered to minimize any adverse impact on the surroundings.

Troubleshooting and Common Issues

Here are some common troubleshooting tips and solutions related to the Replacement Of AH210891 Hydraulic Cylinder:

- Issue: Cylinder does not extend or retract properly.

- Issue: Cylinder leaks or seals are damaged.

- Issue: Cylinder is experiencing excessive vibration or noise.

Solution: Check for low hydraulic fluid levels or a clogged filter. Clean or replace the filter and refill the hydraulic fluid as necessary.

Solution: Inspect the seals for wear or damage and replace them if necessary. Ensure proper installation and lubrication to prevent future leaks.

Solution: Check for loose mounting brackets or misalignment. Tighten the brackets and realign the cylinder to eliminate vibration and noise.

By following these troubleshooting tips, readers can effectively diagnose and resolve issues related to the Replacement Of AH210891 Hydraulic Cylinder. It is crucial to implement preventive measures to minimize potential problems.

Design Considerations and Selection Criteria

When selecting the Replacement Of AH210891 Hydraulic Cylinder, it is essential to consider the following design factors:

- Load-bearing Capacity: The cylinder should be capable of handling the intended load without compromising performance or safety.

- Sealing: High-quality seals, such as piston seals and rod seals made of wear-resistant materials like polyurethane or nitrile rubber, ensure optimal sealing performance.

- Durability: The cylinder body and threaded ends should undergo meticulous surface treatment to enhance wear resistance and longevity.

- Safety: Design features such as overload protection mechanisms and secure mounting brackets contribute to the overall safety of the hydraulic cylinder.

- Maintainability: Easy access to key components and standardized parts enable efficient maintenance and repair processes.

The Replacement Of AH210891 Hydraulic Cylinder meets these design considerations and selection criteria, making it a reliable choice for various applications.

Sealing and Lubrication

The Replacement Of AH210891 Hydraulic Cylinder incorporates various sealing elements to ensure efficient operation. These include piston seals, rod seals, and other relevant components. To enhance longevity and performance:

- Sealing components are made of durable materials, such as polyurethane and nitrile rubber, that can withstand wear and tear.

- The cylinder body and threaded ends undergo precise surface treatment to improve wear resistance and prevent leakage.

- Regular lubrication is essential to reduce friction and wear. It is recommended to use the appropriate hydraulic oil and lubricate the cylinder at regular intervals.

Regular Inspection and Preventive Maintenance

To ensure optimal performance and longevity of the Replacement Of AH210891 Hydraulic Cylinder, the following preventive maintenance tasks should be performed:

- Schedule regular inspections to identify any signs of damage, leaks, or abnormal wear.

- Properly lubricate the cylinder using the recommended hydraulic oil to minimize friction and wear.

- Replace worn seals and perform calibration checks to maintain optimal performance.

By implementing these maintenance

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: