Replacement Of BXE10603 Hydraulic Cylinder Kit

Являясь одним из производителей, поставщиков и экспортеров механической продукции, мы предлагаем гидравлические цилиндры и многие другие изделия.

Пожалуйста, свяжитесь с нами для получения подробной информации.

Почта:sales@hydraulic-cylinders.net

Производитель поставщик экспортер гидроцилиндров.

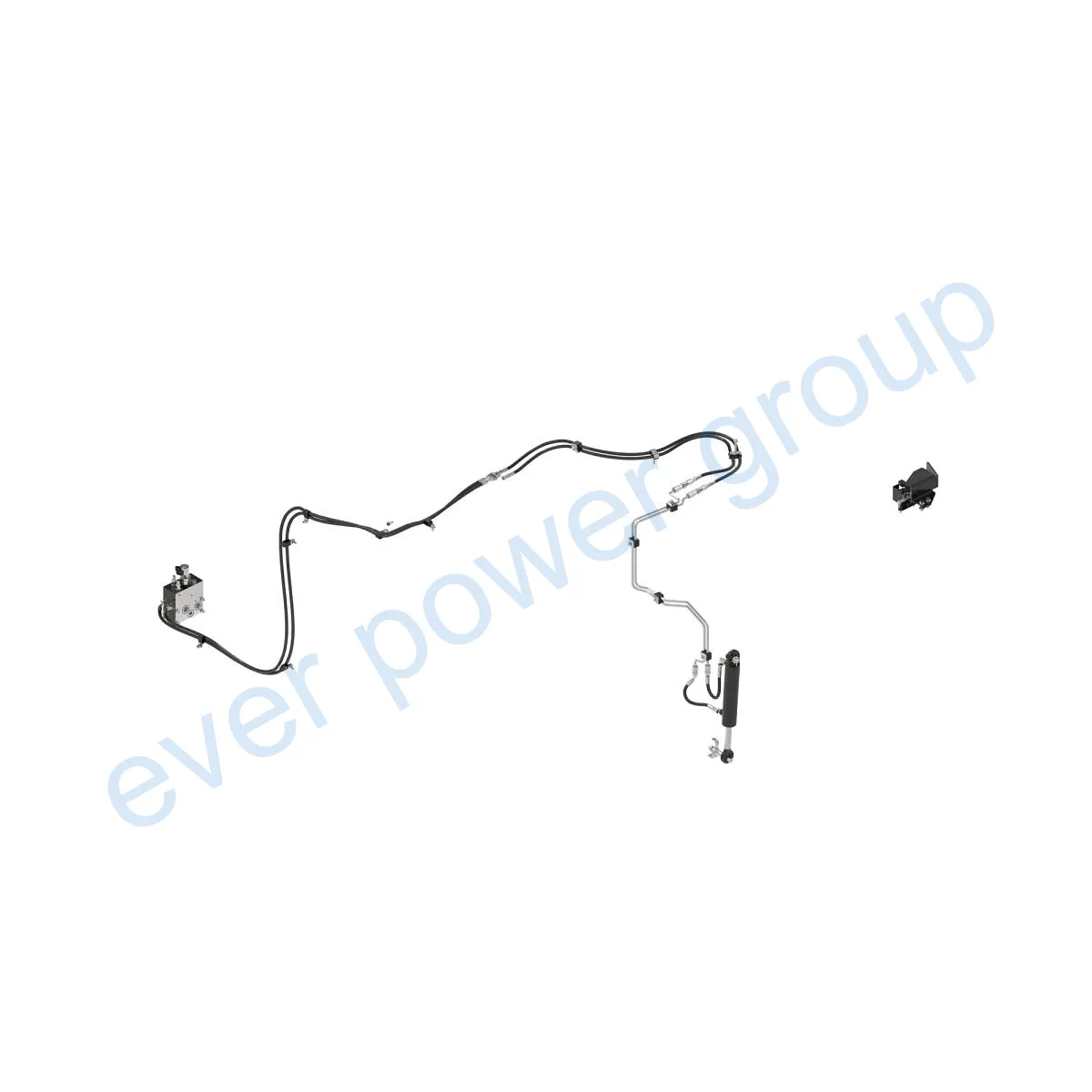

Replacement Of BXE10603 Hydraulic Cylinder Kit

First, let’s introduce the product and define what this hydraulic cylinder is and its purpose. The Replacement Of BXE10603 Hydraulic Cylinder Kit is a high-quality replacement kit designed for the 8100, 8200, 8300, 8400, 8500, and 8600 models. It is built to withstand heavy-duty applications and ensure optimal performance.

Specifications

- Weight: 44 lb

- Height: 10.2 in

- Width: 15.6 in

- Length: 34.4 in

Compatible Models

- 8100

- 8200

- 8300

- 8400

- 8500

- 8600

Product Features

- 1. High-quality construction: The Replacement Of BXE10603 Hydraulic Cylinder Kit is made from durable materials to ensure long-lasting performance.

- 2. Easy installation: This kit is designed for easy installation, allowing for quick replacement and minimal downtime.

- 3. Versatile compatibility: It is compatible with multiple models, providing a convenient solution for various applications.

- 4. Superior functionality: The hydraulic cylinder kit offers excellent performance, enhancing the efficiency and productivity of your equipment.

- 5. Cost-effective alternative: By choosing this replacement kit, you can save on expensive OEM parts without compromising on quality.

Applications

The Replacement Of BXE10603 Hydraulic Cylinder Kit finds its applications in various industries:

Construction:

Commonly used in construction equipment such as cranes, hoists, and elevators where a secure and reliable fixation of heavy loads is required.

Manufacturing:

Utilized in hydraulic presses for shaping materials under high pressure, where a stable and secure hold is necessary during the manufacturing process.

Transportation:

Found in stabilizers and jacks for vehicles, ensuring safety during maintenance or transportation processes.

Aviation:

Used in landing gear systems to securely lock the landing gear in the proper position during takeoff and landing, ensuring the safety of the aircraft.

Design Considerations and Selection Criteria

When selecting the Replacement Of BXE10603 Hydraulic Cylinder Kit, several design considerations and criteria come into play:

Load-bearing capacity:

The hydraulic cylinder kit is designed to handle heavy loads and provide reliable support for various applications.

Sealing:

The kit incorporates various sealing components such as piston seals and rod seals made of wear-resistant materials like polyurethane and nitrile rubber to ensure effective sealing and prevent leakage.

Durability:

The cylinder body and threaded ends of the kit undergo meticulous surface treatment to enhance wear resistance and prolong the lifespan of the hydraulic cylinder.

Safety:

The Replacement Of BXE10603 Hydraulic Cylinder Kit complies with safety standards and includes safety features to prevent accidents during operation.

Maintenance:

Regular maintenance and inspections are necessary to ensure optimal performance and longevity of the hydraulic cylinder. Proper lubrication with the right amount of hydraulic oil is crucial for smooth operation.

Inspection and Preventive Maintenance Measures

To maximize the lifespan of the Replacement Of BXE10603 Hydraulic Cylinder Kit, the following measures should be taken:

1. Regular inspections:

Inspect the hydraulic cylinder for any signs of wear, damage, or leaks. Check the mounting brackets, fasteners, and connections for tightness and stability.

2. Proper lubrication:

Ensure that the cylinder is adequately lubricated with the recommended hydraulic oil to minimize friction and wear.

3. Seal replacement:

Monitor the condition of the seals and replace them if signs of wear or leakage are detected.

Correct alignment:

During installation, provide proper guidance for aligning the cylinder to prevent misalignment and potential damage.

Recommended maintenance and repair procedures:

Follow the recommended procedures provided by the manufacturer for maintenance, repairs, and part replacements. Consider utilizing rebuild services to extend the lifespan of the hydraulic cylinder.

Tips for increasing the lifespan:

Implement techniques such as regular inspections, proper lubrication, and preventive measures to enhance the durability and longevity of the Replacement Of BXE10603 Hydraulic Cylinder Kit.

Safety Considerations and Environmental Factors

When working with hydraulic cylinders, it is essential to prioritize safety measures. Some important safety considerations include:

1. Adhere to safety protocols and guidelines to prevent accidents and injuries.

2. Use appropriate personal protective equipment (PPE) when handling or working near hydraulic cylinders.

3. Ensure proper training and qualification of personnel involved in the installation, maintenance, and operation of hydraulic cylinders.

4. Consider environmental factors such as temperature, humidity, and exposure to corrosive substances that may affect the performance and lifespan of the hydraulic cylinder.

Fault Diagnosis and Common Issues

The following are some common fault diagnoses and issues that may arise:

1. Leakage:

If there is visible leakage, inspect the seals and connections for damage or improper installation.

2. Insufficient force:

Check for any restrictions in the hydraulic lines, insufficient hydraulic oil, or worn-out components that may affect the force output.

3. Abnormal noise:

Unusual noises may indicate internal damage or inadequate lubrication. Inspect the cylinder for any worn or faulty parts.

4. Slow operation:

Inadequate lubrication, low hydraulic pressure, or worn-out seals could cause slow operation. Address these issues promptly to restore optimal performance.

Troubleshooting Tips and Solutions

For effective troubleshooting and problem-solving, consider the following tips:

1. Leakage:

If leakage is detected, ensure proper installation of seals and connections. Replace damaged seals and tighten connections as necessary.

2. Insufficient force:

Check for any blockages or restrictions in the hydraulic lines. Ensure the hydraulic oil level is sufficient and replace worn-out components if needed.

3. Abnormal noise:

If abnormal noise is present, inspect the cylinder for any damaged or worn-out parts. Lubricate the cylinder properly and replace any faulty components.

4. Slow operation:

Check the lubrication levels and ensure the hydraulic pressure is within the recommended range. Replace worn-out seals and components if necessary.

About Our Company

We are a leading manufacturer and wholesale distributor of hydraulic cylinders, specializing in the production of replacement hydraulic cylinders. Our extensive range of products makes us a prominent player in both domestic and international markets.

Our company stands out for:

Professionalism:

We have a team of experienced professionals dedicated to delivering high-quality hydraulic cylinder solutions.

International certifications:

All our products meet internationally recognized standards and undergo rigorous quality control processes.

Customization services:

We offer customization options to meet specific customer requirements and ensure optimal performance.

State-of-the-art production facilities:

Our advanced manufacturing equipment enables us to produce hydraulic cylinders with precision and efficiency.

Exceptional after-sales service:

We provide comprehensive after-sales support, including technical assistance, maintenance guidance, and prompt response to customer queries.

Remember to organize the article logically, use subheadings for easy navigation, include relevant images or charts to enhance understanding, and ensure the content is clear, concise, and suitable for readers with varying technical knowledge levels.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: