V30E Series Axial Piston Variable Displacement Hydraulic Pump

Являясь одним из производителей, поставщиков и экспортеров механической продукции, мы предлагаем гидравлические цилиндры и многие другие изделия.

Пожалуйста, свяжитесь с нами для получения подробной информации.

Почта:sales@hydraulic-cylinders.net

Производитель поставщик экспортер гидроцилиндров.

V30E Series Axial Piston Variable Displacement Hydraulic Pump

The V30E series axial piston variable displacement hydraulic pump is an exceptional solution designed to elevate the performance and efficiency of hydraulic systems. With its advanced features, precise control, and robust construction, this hydraulic pump sets a new standard in the industry.

The V30E series axial piston variable displacement hydraulic pump is a game-changer in hydraulic systems. Its variable displacement capability, high performance, and versatile design offer precise control, enhanced efficiency, and exceptional power delivery. By following the recommended usage methods and adhering to regular maintenance practices, the V30E series pump will continue to deliver outstanding performance, efficiency, and reliability. Embrace the power and efficiency of the V30E series axial piston variable displacement hydraulic pump to unlock the full potential of your hydraulic system.

V30E Series Axial Piston Variable Displacement Hydraulic Pump Key Characteristics:

- Variable Displacement Capability: The V30E series pump boasts advanced variable displacement technology, allowing it to adjust its output according to the system’s demand. This feature ensures optimal energy utilization, enhancing efficiency and reducing power consumption.

- High Performance and Power: With its exceptional design and engineering, the V30E series pump delivers outstanding performance and power. It operates seamlessly across various pressures and speeds, providing precise control and efficient power delivery for superior system performance.

- Versatile Design for Diverse Applications: The V30E series pump is designed to adapt to various hydraulic systems and applications. It offers versatility in mounting options, fluid compatibility, and control methods, making it suitable for various industries and machinery.

- Efficiency at Any Load: The variable displacement feature of the V30E series pump ensures efficiency across a broad range of loads. It minimizes energy losses and productivity, even under varying operating conditions by automatically adjusting the output to match the system’s requirements.

V30E Series Axial Piston Variable Displacement Hydraulic Pump Parameter:

| Size | Displacement cc/rev | Pressure bar | Rotation speed r/min | ||

| Rated | Peak | Max for self-priming*1 | Max*2 | ||

| V30E75 | 75 | 400 | 450 | 2800 | 3000 |

| V30E95 | 98 | 350 | 420 | 2500 | 2900 |

| V30E160 | 160 | 350 | 420 | 2100 | 2500 |

| V30E270 | 270 | 350 | 420 | 1800 | 2000 |

| V30E280 | 280 | 350 | 420 | 2300 | 2300 |

V30E Series Axial Piston Variable Displacement Hydraulic Pump Advantages:

• Applied in open circuit hydraulic systems

• Low noise

• Multiple control modules

• Strong structure

• Compact structure, high power density

• Long life

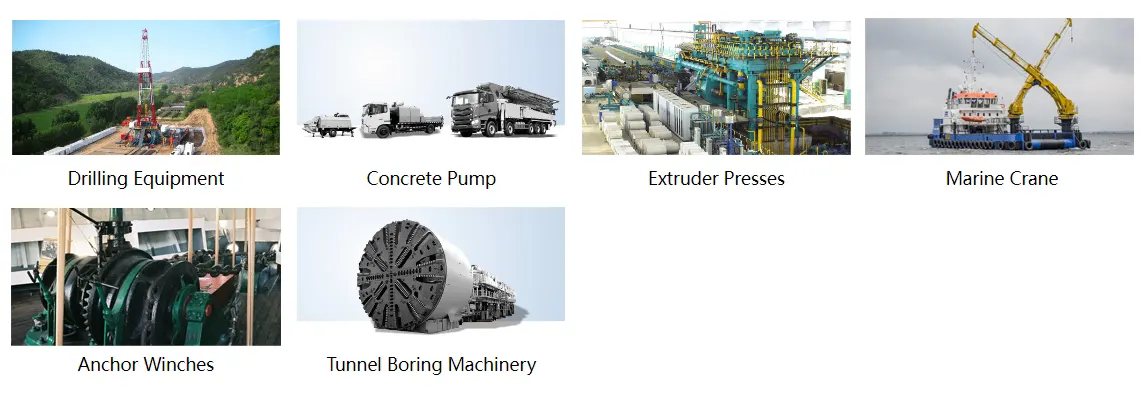

V30E Series Axial Piston Variable Displacement Hydraulic Pump Application:

Usage Method Of V30E Series Axial Piston Variable Displacement Hydraulic Pump:

- Installation and Integration: Select an appropriate location within the hydraulic system to install the V30E series axial piston variable displacement hydraulic pump. Ensure proper alignment and securely mount the pump using suitable brackets or accessories. Connect the pump to the hydraulic system using compatible fittings and hoses, ensuring leak-free connections.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the V30E series pump. Refer to the manufacturer’s recommended fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure optimal pump operation and longevity.

- Control and Adjustment: Familiarize yourself with the control options provided with the V30E series pump. Depending on the specific model, it may offer various control methods, such as manual, proportional, or electronic control. Understand the recommended control settings and adjust them accordingly to optimize pump performance.

- System Optimization: The V30E series pump allows system optimization by adjusting the pump’s displacement to match the load requirements. Take advantage of this feature to maximize energy efficiency and overall system performance.

How To Disassemble A Hydraulic Cylinder?

Disassembling a hydraulic cylinder requires careful handling and knowledge of the cylinder’s components. Here is a general guide to help you disassemble a hydraulic cylinder:

- Safety First: Before starting the disassembly process, ensure the hydraulic system is depressurized and the hydraulic fluid is drained completely. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from potential hazards.

- Gather Tools and Equipment: Prepare the necessary tools and equipment for disassembly. This may include wrenches, sockets, pliers, a rubber mallet, a pry bar, and a clean work surface.

- Cylinder Preparation: Remove any external attachments or accessories from the hydraulic cylinder, such as mounting brackets or hoses. Clean the exterior of the cylinder to prevent dirt or debris from entering during disassembly.

- Disconnect Hydraulic Lines: Identify the hydraulic lines connected to the cylinder. Use appropriate tools to disconnect the fittings or couplings, ensuring you catch any residual hydraulic fluid in a suitable container.

- Remove End Caps and Retaining Bolts: Locate the end caps on the cylinder. These are typically secured with retaining bolts or screws. Remove the retaining bolts to release the end caps using the appropriate tools.

- Release Piston and Rod: With the end caps removed, the piston and rod assembly should be accessible. Tap the rod with a rubber mallet to loosen it from the cylinder. Slowly pull the piston and rod assembly out of the cylinder bore. Take note of any seals or bearings that may come with the community.

- Inspect and Replace Components: Once the cylinder is disassembled, carefully inspect each component for wear, damage, or leaks. Replace any worn or damaged seals, bearings, or other details. Clean all parts thoroughly using an appropriate solvent.

- Сборка: To reassemble the hydraulic cylinder, follow the reverse order of disassembly. Lubricate the seals and components with hydraulic fluid to ensure smooth assembly. Care to properly align the piston and rod assembly within the cylinder bore. Secure the end caps with the retaining bolts, ensuring proper torque specifications.

- Test and Reinstall: After reassembly, thoroughly inspect the cylinder to ensure all components are correctly installed. Reconnect the hydraulic lines and pressurize the system gradually. Check for any leaks or abnormal operations. If everything functions correctly, reinstall the hydraulic cylinder into its intended location.

Возможности и мощности завода:

(1) Сборка

Мы располагаем первоклассной независимой сборочной платформой для проведения исследований и разработок. Цех по производству гидравлических цилиндров имеет четыре полуавтоматические линии сборки подъемных цилиндров и одну автоматическую линию сборки цилиндров наклона с проектной годовой производственной мощностью 1 млн. штук. Цех по производству специальных цилиндров оснащен полуавтоматической очистной сборочной системой различных спецификаций с проектной годовой производственной мощностью 200 тыс. штук и оснащен известным обрабатывающим оборудованием с ЧПУ, обрабатывающим центром, высокоточным специальным оборудованием для обработки цилиндров, роботом-сварщиком, автоматической очистной машиной, автоматической сборочной машиной цилиндров и автоматической покрасочной производственной линией. Существующее критически важное оборудование насчитывает более 300 комплектов (комплектов). Оптимальное распределение и эффективное использование ресурсов оборудования позволяет обеспечить требования к точности изделий и удовлетворить потребности в высоком качестве продукции.

(2) Механическая обработка

Цех оснащен специализированным токарным центром с наклонной направляющей, обрабатывающим центром, высокоскоростным хонинговальным станком, сварочным роботом и другим сопутствующим оборудованием, которое позволяет обрабатывать цилиндрические трубы с максимальным внутренним диаметром 400 мм и максимальной длиной 6 м.

(3) Сварка

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: