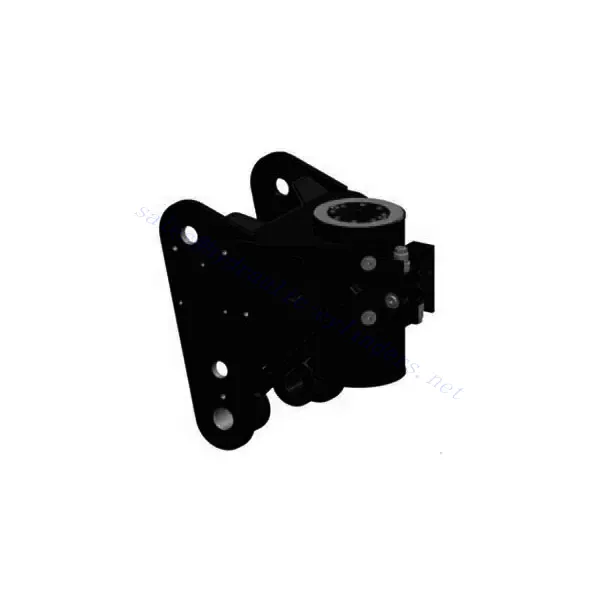

Aerial Work Platform Rotary Actuator

Aerial Work Platform Rotary Actuator

HBM series rotary actuator is a rotary actuator independently designed and developed for the arms control of articulated aerial work platforms. According to customer installation and performance requirements, the corresponding customized design can be realized to ensure the adaptability and flexibility of operation.

Based on the metric unit design, the unique seal and construction allow for a low coefficient of friction and high output torque. In addition, finite element analysis and durability testing contribute to the stability and reliability of the product. Compared with similar products on the market, the HBM series rotary actuator under the same product size, the output torque is increased by 10% ~ 20%, the cracking pressure is reduced by 50%, the operation is stable, the efficiency is higher, the cracking pressure is better, and finally ensure the safe, reliable and efficient work of the high-altitude working platform.

Aerial Work Platform Rotary Actuator Key Characteristics:

- Low Friction Coefficient:

- The critical component of the HBM series rotary actuator – the spiral spline for rotation and torque transmission,

features excellent precision, balanced stress distribution, and stable transmission. With the low-friction axial bearings and a unique sealing system design, the HBM series rotary actuator has a low friction coefficient during transmission.

- High Output Torque:

- Through continuous innovative research and validations, the HBM series rotary actuator is designed compactly to fully use the limited internal space and transmit high output torque via fluid pressure. Compared to similar products, the HBM series rotary actuator provides a 10% to 20% higher output torque under the same product size.

- Long Service Life:

- Comprehensive analysis and calculation on each size of the HBM rotary actuator are implemented with the assistance of FEA software during the design process. Besides, product optimization is continuously carried out to ensure that each product size can meet the long service life requirements.

- Except for regular factory tests, two dedicated rotary actuator endurance test benches are available for tests according to customer and application requirements, ensuring excellent durability and long service life.

Aerial Work Platform Rotary Actuator Parameter:

| Product Name | Aerial Work Platform Rotary Actuator |

| Features: | Realize platform and crank arm swing |

| Torque: | 500~5000N.m |

| Swing angle: | 0~360° |

| Pressure: | 21MPa(standard working pressure) |

| Rotary Actuator Applications: | Aerial Work Platform |

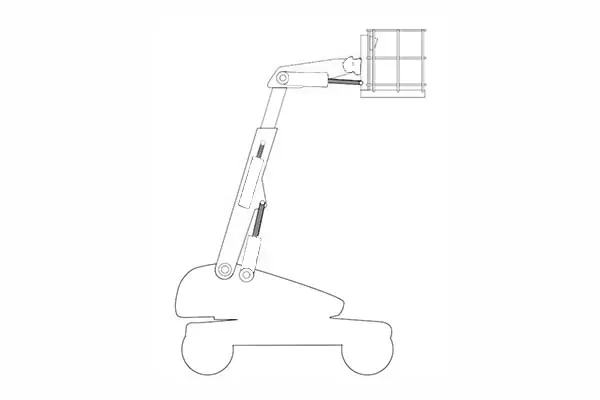

Aerial Work Platform Identification Diagram:

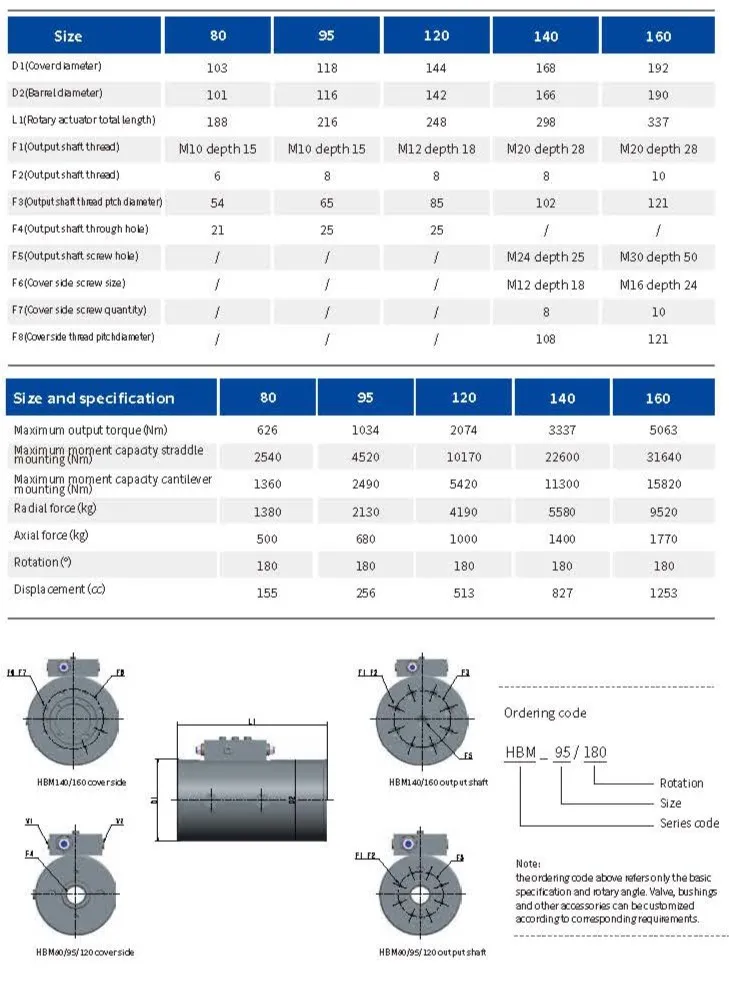

Aerial Work Platform Rotary Actuator Size And Specification:

Usage Method Of Aerial Work Platform Rotary Actuator:

- Actuator Installation:

- Follow the manufacturer’s instructions for proper installation of the aerial work platform rotary actuator.

- Ensure the actuator is securely mounted to the aerial work platform’s structure, providing a stable and reliable connection.

- Electrical and Hydraulic Connection:

- Connect the actuator to the electrical and hydraulic systems of the aerial work platform according to the provided guidelines.

- Ensure all connections are secure and properly sealed to prevent leaks or electrical malfunctions.

- Rotation Control:

- Utilize the control panel or interface provided to control the rotational movement of the aerial work platform.

- Follow the recommended operating procedures and safety guidelines for smooth and precise rotation.

- Safety Considerations:

- Before operating the aerial work platform, familiarize yourself with the safety features and emergency procedures.

- Ensure that all operators receive proper training on the safe operation of the platform and the aerial work platform rotary actuator.

How To Bleed Air From A Hydraulic System?

Bleeding air from a hydraulic system is a crucial maintenance procedure to ensure optimal performance and prevent spongy or inconsistent hydraulic operation. Here’s a step-by-step guide on how to bleed air from a hydraulic system:

- Identify Bleed Points:

- Locate the bleed points in the hydraulic system. These are typically found at high energies, such as on top of hydraulic cylinders, control valves, or pump reservoirs.

- Consult the hydraulic system’s manual or manufacturer’s guidelines to identify the specific bleed points for your system.

- Prepare the System:

- Turn off the power to the hydraulic system and relieve pressure by lowering or retracting hydraulic cylinders or releasing the pressure valve.

- Ensure you have the necessary tools and safety equipment to perform the bleeding process, including safety goggles and gloves.

- Position a Collection Container:

- Place a suitable container or drain pan beneath the bleed point to collect any hydraulic fluid that may be released during the bleeding process.

- This will help prevent spills and keep your work area clean.

- Open the Bleed Valve:

- Slowly and partially open the bleed valve at the designated bleed point using an appropriate wrench or tool.

- Be cautious not to fully remove the valve at this stage; instead, create a small opening to allow air and fluid to escape.

- Begin Bleeding:

- With the bleed valve partially open, activate the hydraulic system by turning it on or operating the relevant controls.

- Allow the hydraulic fluid to flow through the system, pushing out any trapped air bubbles. You will notice air and fluid escaping through the partially opened bleed valve.

- Monitor and Repeat:

- Monitor the fluid flow and observe any air bubbles escaping from the bleed valve.

- Once the fluid flow is consistent and free of air bubbles, close the bleed valve tightly to prevent any further air from entering the system.

- If air bubbles persist, repeat the bleeding process by partially opening the bleed valve again and allowing more fluid to flow through until the air is eliminated.

- Check Fluid Levels:

- After bleeding the air, check the hydraulic fluid level in the system’s reservoir or tank.

- Add additional fluid if necessary to maintain the recommended fluid level.

- Test and Verify:

- With the bleeding process completed and the hydraulic system reassembled, test the system’s operation to ensure smooth and consistent hydraulic performance.

- Verify that there are no unusual sounds or vibrations and that the system responds correctly to control inputs.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: