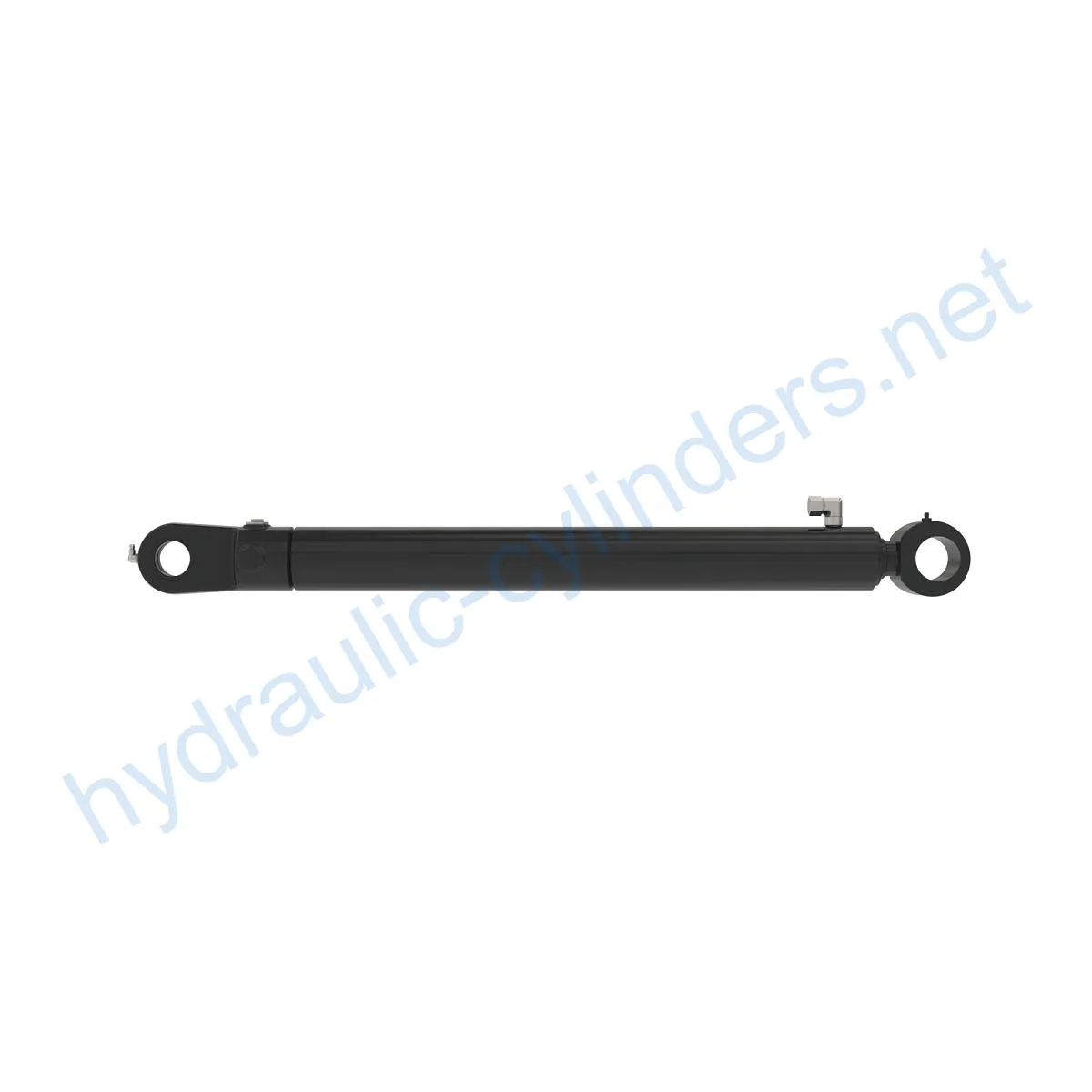

Replacement Of AHC17478 Hydraulic Cylinder

Replacement Of AHC17478 Hydraulic Cylinder

Introduction:

The Replacement Of AHC17478 Hydraulic Cylinder is a crucial component used in various equipment, such as excavators, cranes, tractors, harvesters, and more. It plays a vital role in the smooth operation and performance of these machines by providing the necessary power for lifting, pushing, and moving heavy loads.

Specifications and Model:

- Weight: 56.65 lb

- Height: 4.5 in

- Width: 5.5 in

- Length: 44 in

- Model: 324G 325G

Features:

- Improved Equipment Performance: Replacing damaged or worn-out hydraulic cylinders can restore the normal operational capability of the equipment, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety risks caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: Modern cylinder designs often incorporate better overload protection mechanisms, enhancing overall safety.

- Quick Installation: The design of modern hydraulic cylinders considers easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, facilitating the acquisition of replacement parts in the market.

Applications:

The Replacement Of AHC17478 Hydraulic Cylinder finds versatile applications in various industries. Here are some examples:

- Excavators: The hydraulic cylinder may require replacement in the arm or bucket of an excavator due to prolonged use or overloading, ensuring smooth operation.

- Cranes: The boom hydraulic cylinder of a crane experiences wear during frequent lifting and lowering processes, necessitating regular replacement for safety.

- Tractors: The front-end loader hydraulic cylinder in tractors may develop leaks or performance degradation during continuous lifting and tilting operations, requiring replacement.

- Harvesters: Hydraulic cylinders in harvesting equipment endure high pressure during the harvesting process, and timely replacement ensures sustained work efficiency.

- Automated Production Lines: Hydraulic cylinders control robotic arms and other automated equipment. Immediate replacement is necessary in case of any cylinder failure to maintain production efficiency.

Maintenance Tasks:

To ensure the longevity and optimal performance of the Replacement Of AHC17478 Hydraulic Cylinder, several maintenance tasks should be performed:

- Regular Inspection: Periodically inspecting the hydraulic cylinder for any signs of damage or wear is essential for early detection and prevention of potential issues.

- Proper Lubrication: Adequate lubrication helps reduce friction and wear, enhancing the overall lifespan of the cylinder. It is recommended to use the appropriate hydraulic oil for lubrication.

- Seal Replacement: Over time, seals may wear out, leading to leaks. Regularly replacing seals ensures proper functioning and prevents fluid leakage.

- Calibration Check: Periodically checking and calibrating the hydraulic cylinder ensures accurate and precise operation, contributing to the overall equipment performance.

Safety Considerations and Environmental Factors:

When utilizing the Replacement Of AHC17478 Hydraulic Cylinder, it is crucial to prioritize safety measures. Proper handling, installation, and maintenance are vital to prevent accidents and ensure operator safety. Additionally, considering environmental factors during the disposal of old cylinders is essential to minimize any negative impact.

Troubleshooting and Common Issues:

Here are some common troubleshooting tips and solutions related to the Replacement Of AHC17478 Hydraulic Cylinder:

- Issue: Cylinder Leakage

Solution: Check for damaged seals and replace them if necessary. Inspect for any signs of cylinder damage or misalignment. - Issue: Cylinder Not Extending or Retracting Properly

Solution: Check for obstructions or blockages in the hydraulic lines. Ensure the hydraulic fluid level is appropriate and the pump is functioning correctly. - Issue: Cylinder Overheating

Solution: Verify that the system’s hydraulic fluid is within the recommended temperature range. Check for any restrictions in the fluid flow and ensure proper ventilation.

Design Considerations and Selection Criteria:

The design of the Replacement Of AHC17478 Hydraulic Cylinder takes into account several key factors:

- Load-bearing Capacity: The cylinder design ensures it can handle the required load capacity effectively.

- Sealing: High-quality seals, such as piston seals and rod seals made of durable materials like polyurethane and nitrile rubber, provide optimal sealing performance.

- Durability: The cylinder body and threaded ends undergo precise surface treatments to enhance wear resistance and prolong the cylinder’s lifespan.

- Safety: The cylinder design incorporates safety features to prevent overloading and ensure operator security.

- Maintainability: The design facilitates easy maintenance, including disassembly and reassembly, replacement of components, and rebuild services.

Sealing and Lubrication:

The Replacement Of AHC17478 Hydraulic Cylinder utilizes various sealing elements and lubrication techniques:

- Seal Variety: Different types of seals, such as piston seals and rod seals, are utilized for effective sealing and prevention of leakage.

- Durable Materials: Seals are constructed using wear-resistant materials like polyurethane and nitrile rubber to ensure extended service life.

- Surface Treatment: The cylinder body and threaded ends undergo precise surface treatments to enhance wear resistance and minimize friction.

- Regular Lubrication: Adequate hydraulic oil lubrication is necessary to reduce friction and wear, ensuring optimal performance of the cylinder.

Regular Inspection and Preventive Maintenance:

Regular inspection and preventive maintenance are crucial for the Replacement Of AHC17478 Hydraulic Cylinder:

- Proper Installation: Ensuring correct alignment during the cylinder installation process is essential for optimal performance.

- Appropriate Lubrication: Adequate lubrication with the recommended hydraulic oil helps reduce friction and wear, extending the cylinder’s lifespan.

- Calibration and Adjustment: Periodically calibrating and adjusting the cylinder ensures accurate and efficient operation, contributing to overall equipment performance.

- Guided Cylinder Alignment: Providing proper guidance for aligning the cylinder during installation is essential for avoiding misalignment issues.

- Recommended Inspection, Repair, and Replacement Procedures: Following recommended inspection, repair, and replacement procedures ensures the cylinder’s longevity and optimal performance.

- Component Replacement and Rebuild Services: Offering replacement parts and rebuild services helps customers maintain and extend the lifespan of their hydraulic cylinders.

- Techniques to Improve Lifespan: Providing tips and techniques to improve the lifespan of the Replacement Of AHC17478 Hydraulic Cylinder, such as proper maintenance and usage, can maximize its durability.

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: