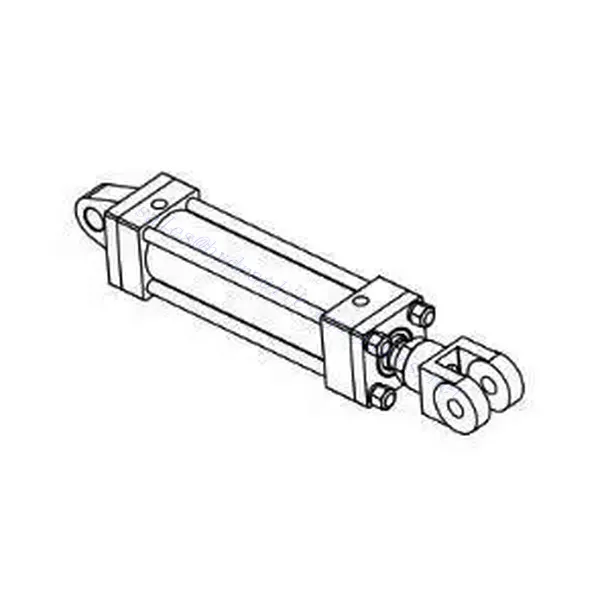

CA 单耳式 Y 型连接器 重型杆液压缸

CA 单耳式 Y 型连接器 重型杆液压缸

CA monaural type Y connector heavy rod hydraulic cylinders are essential for various industrial applications. This hydraulic cylinder delivers reliable and precise performance with its rugged construction, versatile Y-connector design, and heavy-duty functionality. Whether you need to lift, push, or pull a heavy load, the CA monaural type Y connector heavy rod hydraulic cylinder provides the best power and efficiency.

重型杆式液压缸的基本特征:

坚固的结构 This hydraulic cylinder features a rugged construction using high-quality materials, ensuring durability and longevity. Its sturdy design allows it to withstand heavy loads, high pressures, and harsh operating conditions, making it ideal for demanding industrial environments.

单声道 Y 型连接器: 单声道 Y 型连接器设计增强了稳定性和可控性。通过 Y 型连接器配置,气缸可实现精确定位和平稳操作,最大程度地降低了使用过程中发生错位或偏移的风险。

重棒 The heavy rod design of the CA monaural type Y connector hydraulic cylinder enables it to produce a large amount of force output. This feature makes it suitable for applications that require lifting, pushing, or pulling heavy loads quickly and precisely.

CA 单耳式 Y 型连接器重杆液压缸参数:

CA 单耳式 Y 型连接器重杆液压缸的使用方法:

安装: 首先使用适当的支架或固定装置牢固安装 CA 单耳 Y 型连接器重杆液压缸。在安装过程中确保正确的对齐和稳定性,以防止错位或对油缸造成过大压力。

液压系统集成: 按照制造商的说明和指导,将液压管路连接到油缸的 Y 型接头。将油缸连接至合适的泵或动力装置,将其纳入液压系统。确保与油缸的规格和操作要求兼容。

控制和操作: 利用液压系统中的控制阀调节液压油进出油缸的流量。调整控制设置,以实现所需的线性运动和力输出。测试液压缸的运动,以验证其功能和响应性。

CA 单耳式 Y 型连接器重杆液压缸的维护保养:

定期维护对确保 CA 单耳式 Y 型接头重杆液压缸的最佳性能和使用寿命至关重要。请遵循以下维护指南:

定期检查: 进行例行检查,找出磨损、损坏或泄漏迹象。检查气缸体、拉杆、密封件和其他部件是否异常。及时解决任何问题,以防止进一步的伤害或运行效率低下。

润滑: 给气缸的活动部件,包括拉杆和密封件,涂上建议的润滑油。定期润滑可最大限度地减少摩擦、降低磨损并确保平稳运行。根据制造商的润滑间隔指南使用适当类型的润滑油。

更换密封件: 如果发现密封件老化或泄漏,请使用制造商认可的原装部件更换密封件。损坏或磨损的密封件会影响油缸的性能并导致液压油泄漏。

清洁: 清洁气缸,清除灰尘、碎屑和其他污染物。在重新装配之前,使用非研磨性清洁剂,并确保所有部件都处于干燥状态。定期清洁可提高最佳性能,防止过早磨损或损坏。

How Do You Size A Hydraulic Cylinder?

Sizing a hydraulic cylinder involves determining the appropriate specifications and dimensions of the cylinder to ensure it can effectively perform the desired task. Here are the general steps involved in sizing a hydraulic cylinder:

- Determine the Required Force: Start by calculating the force required to move or perform the intended task. Consider factors such as the weight of the load, the required acceleration or speed, and any additional forces acting on the system. This force requirement will help determine the minimum force capacity of the hydraulic cylinder.

- Evaluate the Working Pressure: Determine the maximum working pressure of the hydraulic system in which the cylinder will operate. The working pressure should be sufficient to generate the required force calculated in the previous step. Ensure the hydraulic system, including the pump, valves, and hoses, can handle the anticipated pressure.

- Calculate the Cylinder Bore Size: The bore size of the cylinder is a critical factor in determining its force capacity. Use the formula: Force (F) = Pressure (P) x Area (A), where the force is in pounds or Newtons, the pressure is in pounds per square inch (psi) or Pascal (Pa), and the area is in square inches or square meters. Rearrange the formula to calculate the required cylinder bore size: Bore Size = √(Force / (Pressure x π)).

- Consider Stroke Length: Determine the required stroke length the maximum distance the cylinder needs to extend or retract to fulfill its intended function. Ensure the selected cylinder has a stroke length that accommodates the desired movement.

- Account for Safety Factors: Consider adding a safety factor to the calculated force requirement to ensure the cylinder can handle unexpected loads or variations in operating conditions. A standard safety factor is 1.5 to 2 times the estimated force.

- Check Speed and Fluid Flow: Consider the desired speed of the cylinder’s movement and ensure that the hydraulic system can provide the necessary fluid flow rate to achieve that speed. Avoid excessive speeds that may compromise safety or cause system instability.

- Consult Manufacturer Data and Guidelines: Refer to manufacturer catalogs, technical data sheets, and guidelines for specific cylinder models. Manufacturers often provide sizing charts, performance data, and selection guidelines to assist in choosing the appropriate cylinder for your application.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

我们是最好的重型连杆液压缸制造商之一。我们可以提供广泛的重型连杆液压缸库存。我们还提供相应的 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: