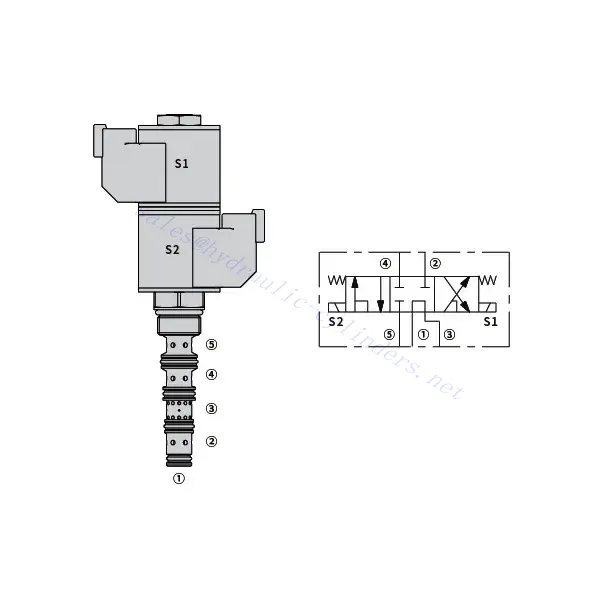

35SD10-58C Solenoid Directional Valve

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

35SD10-58C Solenoid Directional Valve

The 35SD10-58C solenoid directional valve is a cutting-edge component designed to provide precise control over hydraulic systems. With its advanced features and robust construction, this valve ensures optimal fluid direction and control, making it an indispensable tool for a wide range of applications. Whether you’re operating heavy machinery, managing industrial equipment, or overseeing complex hydraulic systems, the 35SD10-58C solenoid directional valve delivers the precision and performance you need.

The 35SD10-58C solenoid directional valve is a reliable and high-performance component for achieving precise control and efficient fluid direction in hydraulic systems. With its exceptional control capabilities, enhanced durability, efficient fluid direction, and versatility, this valve delivers the reliability and performance needed across a range of applications. By following the recommended usage methods and maintenance practices, you can ensure optimal performance and extend the lifespan of your 35SD10-58C solenoid directional valve. Invest in this high-quality valve today and experience enhanced control and reliability in your hydraulic system.

35SD10-58C Solenoid Directional Valve Characteristics:

- Precise Control: The 35SD10-58C solenoid directional valve offers exceptional control over the flow of hydraulic fluid. Its innovative design enables rapid and accurate switching between flow paths, ensuring precise control over hydraulic actuators and other components. With this level of control, you can achieve optimal performance and efficiency in your hydraulic system.

- Enhanced Durability: This valve is built to withstand demanding and prolonged use. Its sturdy construction and high-quality materials ensure durability and reliability, even in harsh operating environments. With the 35SD10-58C solenoid directional valve, you can rely on consistent performance and minimal maintenance requirements.

- Efficient Fluid Direction: The valve efficiently directs the flow of hydraulic fluid, ensuring smooth and controlled movement. Directing the fluid to the desired path minimizes energy loss, reduces system inefficiencies, and enhances overall productivity. The efficient fluid direction provided by the 35SD10-58C solenoid directional valve translates into cost savings and improved performance.

- Versatility: The 35SD10-58C solenoid directional valve is highly versatile and suitable for various applications. This valve seamlessly adapts to different requirements, whether used in construction equipment, material handling machinery, or industrial automation systems. Its versatility allows it to integrate smoothly into various hydraulic systems, providing optimal control and performance.

35SD10-58C Solenoid Directional Valve Parameter:

| Rated pressure | 240 bar (3500 psi) | |

| Peak flow | 19 L/min (5 gpm) | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 18/16/13, and level 15/13/11 is recommended to prolong the service life | |

| Internal Leakage | ≤ 328 mL/min@240 bar | |

| Cavity | VC10-4 | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 207 bar | |

35SD10-58C Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Industry common cavity

• Hardened parts for long life

Usage Method Of 35SD10-58C Solenoid Directional Valve :

Using the 35SD10-58C solenoid directional valve is straightforward and follows these general steps:

- Mounting: Securely mount the valve in the designated location within your hydraulic system, ensuring proper alignment and connection to the hydraulic lines. Follow the manufacturer’s guidelines for specific mounting instructions.

- Electrical Connection: Following the manufacturer’s electrical wiring diagram, connect the solenoid valve to the appropriate power source. Ensure correct polarity and establish secure electrical connections for seamless valve operation.

- Fluid Connections: Connect the hydraulic lines to the valve ports, ensuring proper alignment and tight connections. Use high-quality fittings and seals to prevent leaks and ensure efficient fluid transfer.

- Valve Operation: Control the operation of the 35SD10-58C solenoid directional valve using electrical control signals. Send the appropriate electrical signals to the solenoid to switch the valve position, directing the flow of hydraulic fluid as needed.

How To Remove A Moen Shower Valve Cartridge?

To remove a Moen shower valve cartridge, follow these steps:

- Turn off the water supply: Locate the main water shut-off valve for the shower and turn it off. This will prevent any water flow while you work on removing the cartridge.

- Remove the handle and trim: Use a screwdriver to remove the screw holding the handle in place. Once the screw is removed, gently pull the handle off. Next, remove any trim or decorative covers that may be hiding additional screws.

- Identify the cartridge type: Moen shower valves can have different types of cartridges, such as the 1222, 1225, or 1224 cartridge models. Identify the specific cartridge model to ensure you have the right removal technique.

- Look for the cartridge retaining clip: Moen cartridges typically have a retaining clip that needs to be removed before the cartridge can be taken out. Locate the clip, which is a metal or plastic piece, and use pliers to carefully remove it by squeezing and pulling it out.

- Use pliers for stubborn cartridges: If the cartridge is still stuck, you can use adjustable pliers to grip the cartridge stem and twist it back and forth to loosen it. Be careful not to apply excessive force, as it may damage the valve body.

- Use a cartridge removal tool (optional): Moen also offers a cartridge removal tool called the Moen Cartridge Puller, which is specifically designed to remove Moen cartridges. Follow the instructions provided with the tool to insert and secure it onto the cartridge, then use it to apply steady and even pressure to remove the cartridge.

- Pull out the cartridge: Once the cartridge is loose, you should be able to pull it straight out of the valve body using your hands or pliers. If necessary, use pliers to grip the cartridge and pull it out completely.

- Clean the valve body: Take a moment to clean any debris or mineral buildup from the valve body using a soft cloth or a toothbrush. Ensure that the valve body is clean and free from any obstructions before installing a new cartridge.

- Install a new cartridge: If you were removing the cartridge for replacement, now is the time to install a new one. Moen cartridges are usually installed by aligning the tabs or grooves on the cartridge with the corresponding notches or slots in the valve body. Insert the cartridge and push it in firmly until it is fully seated.

- Reassemble the shower valve: Follow the reverse steps to reassemble the shower valve. Install the cartridge retaining clip (if applicable), replace the trim, and secure the handle back in place with the screw.

- Turn on the water supply: Once everything is reassembled, turn on the main water supply and test the shower to ensure proper functioning.

Tehtaan kapasiteetti ja kapasiteetti:

(1) Kokoonpano

Meillä on ensiluokkainen riippumaton tutkimus- ja kehitystyön kokoonpanoalusta. Hydraulisylinterien tuotantopajassa on neljä puoliautomaattista nostosylinterin kokoonpanolinjaa ja yksi automaattinen kallistussylinterin kokoonpanolinja, joiden suunniteltu vuotuinen tuotantokapasiteetti on 1 miljoona kappaletta. Erikoissylinterin työpaja on varustettu erilaisilla eritelmillä puoliautomaattisen puhdistusasennuksen kokoonpanojärjestelmällä, jonka suunniteltu vuotuinen tuotantokapasiteetti on 200 000, ja se on varustettu kuuluisilla CNC-työstölaitteilla, työstökeskuksella, korkean tarkkuuden sylinterin käsittelyyn tarkoitetuilla erityislaitteilla, robottihitsauskoneella, automaattisella puhdistuslaitteella, automaattisella sylinterin kokoonpanokoneella ja automaattisella maalaustuotantolinjalla. Olemassa olevat kriittiset laitteet yli 300 sarjaa (sarjaa). Laiteresurssien optimaalinen kohdentaminen ja tehokas käyttö varmistavat tuotteiden tarkkuusvaatimukset ja täyttävät tuotteiden laatuvaatimukset.

(2) Koneistus

Työstöpaja on varustettu räätälöidyllä kaltevalla kiskosorvauskeskuksella, työstökeskuksella, suurnopeus-hiontakoneella, hitsausrobotilla ja muilla vastaavilla laitteilla, joilla voidaan käsitellä sylinteriputkia, joiden sisähalkaisija on enintään 400 mm ja enimmäispituus on 6 metriä.

(3) Hitsaus

(4) Maalaus ja pinnoitus

Pienillä ja keskisuurilla sylinterin automaattisilla vesipohjaisilla maalipinnoituslinjoilla automaattisen robotin lastaus- ja purku- ja automaattisen ruiskutuksen saavuttamiseksi, suunnittelukapasiteetti on 4000 kappaletta vuorossa;

Meillä on myös puoliautomaattinen maalauslinja suurille sylintereille, joka toimii voimaketjulla ja jonka suunnittelukapasiteetti on 60 laatikkoa työvuorossa.

(5) Testaus

Meillä on ensiluokkaiset tarkastustilat ja testialustat, joilla varmistetaan, että sylinterin suorituskyky täyttää vaatimukset.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding maatalousvaihteistot. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and tehdä yhteistyötä kanssamme!

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Hydraulisylinteri Sovellus: