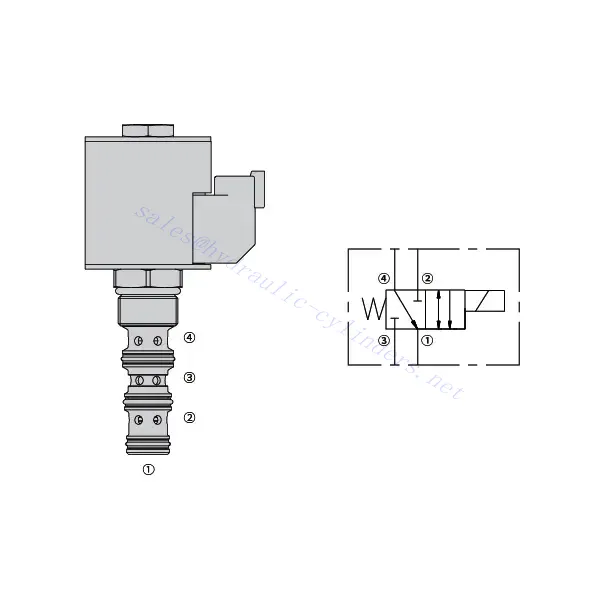

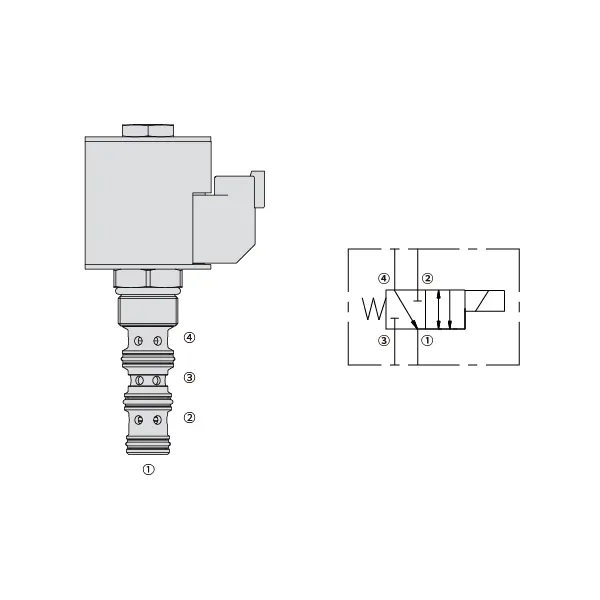

30SD10-43 Solenoid Directional Valve

Mint a hidraulikus hengerek egyik gyártója, szállítója és exportőre a mechanikai termékek, kínálunk hidraulikus hengerek és sok más termék.

Kérjük, lépjen kapcsolatba velünk a részletekért.

Posta:sales@hydraulic-cylinders.net

Hidraulikus hengerek gyártója, szállítója és exportőre.

30SD10-43 Solenoid Directional Valve

The 30SD10-43 solenoid directional valve is a cutting-edge hydraulic component that offers unmatched efficiency and control in various applications. Designed with precision engineering and advanced technology, this valve ensures seamless directional control of hydraulic fluid, allowing for precise and reliable operation in various industries. The 30SD10-43 solenoid directional valve is a trusted solution for optimizing hydraulic systems, from industrial machinery to mobile equipment.

The 30SD10-42 solenoid directional valve is a game-changer for hydraulic systems, providing unparalleled efficiency, control, and reliability. By following the proper usage and maintenance guidelines, you can optimize the performance and longevity of this valve. Invest in the 30SD10-42 solenoid directional valve today and experience the benefits of enhanced precision and efficiency in your hydraulic systems.

30SD10-43 Solenoid Directional Valve Characteristics:

- Durable Construction: The 30SD10-43 solenoid directional valve is built to withstand demanding environments. Constructed from high-quality materials, it offers exceptional durability and longevity, ensuring reliable performance even in harsh conditions.

- High Flow Capacity: This valve boasts a high flow capacity, allowing for efficient and rapid movement of hydraulic fluid. It enables quick response times and enhances the overall productivity of hydraulic systems.

- Easy Installation: The 30SD10-43 solenoid directional valve is designed for easy installation. It features standardized connections and mounting options, making integrating your hydraulic system hassle-free.

- Versatile Applications: This valve is suitable for various applications across various industries. Whether in manufacturing, construction, or agriculture, the 30SD10-43 solenoid directional valve can be tailored to your specific hydraulic control needs.

30SD10-43 Solenoid Directional Valve Parameter:

| Rated pressure | 207 bar(3000 psi) | |

| Peak flow | 23 L/min (6 gpm) | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 20/18/14, and level 17/15/13 is recommended to prolong the service life | |

| Internal Leakage | ≤ 82 mL/min@207bar | |

| Cavity | VC10-4 | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 207 bar | |

30SD10-43 Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Industry common cavity

• Hardened parts for long life

Maintenance Of 30SD10-43 Solenoid Directional Valve:

Regular maintenance is essential to ensure optimal performance and longevity of your 30SD10-43 Solenoid Directional Valve. Follow these maintenance guidelines:

- Regular Inspection: Periodically inspect the valve for any signs of leaks, damage, or wear. Check all connections, seals, and fittings for tightness and integrity. Replace any worn-out or damaged components promptly.

- Lubrication: Apply a suitable lubricant to the valve’s moving parts to reduce friction and ensure smooth operation. Follow the manufacturer’s recommendations for the correct lubricant type and application frequency.

- Cleaning: Clean the valve and surrounding area from dirt, debris, and contaminants. Regularly wipe down the valve with a soft cloth and use a suitable cleaning agent to remove any buildup that may hinder its operation.

- System Flushing: If you notice any contaminants or particles in the hydraulic fluid, consider flushing the system to prevent damage to the valve and other components. Consult the manufacturer’s guidelines or seek professional assistance for proper flushing procedures.

How To Identify Shower Valve Cartridge?

Identifying a shower valve cartridge is crucial when troubleshooting or replacing a faulty cartridge in your shower system. Here are the steps to help you identify the shower valve cartridge:

- Turn off the Water: Before starting any work on your shower, make sure to turn off the water supply. Locate the shut-off valve near the shower or in the main water supply line of your house and close it to stop the water flow.

- Remove the Handle: Depending on the type of shower faucet you have, the handle removal method may vary. Most shower handles have a small screw or setscrew that holds the handle in place. Look for a cap or cover on the handle and use a flathead screwdriver or Allen wrench to remove it. Once the screw or setscrew is exposed, unscrew or loosen it and gently pull off the handle.

- Remove the Trim Plate: After removing the handle, you’ll find a trim plate or escutcheon surrounding the valve. This plate is usually secured with screws or is a threaded piece that can be unscrewed. Use a screwdriver or pliers to remove the screws or twist the trim plate counterclockwise to remove it.

- Identify the Cartridge: With the trim plate removed, you will now have access to the cartridge. The cartridge is a cylindrical component that controls the flow and temperature of the water. Different shower valve cartridges have distinct characteristics that can help with identification.

- Check for Manufacturer’s Markings: Look for any markings or labels on the cartridge. Manufacturers often imprint their logo, part number, or other identifying information on the cartridge body.

- Note the Shape and Size: Observe the shape and size of the cartridge. Cartridges can vary in shape, such as round, cylindrical, or square, and in size, ranging from small to large.

- Count the Number of O-Rings: Count the number of rubber o-rings present on the cartridge. Some cartridges have one o-ring, while others may have two or more.

- Take Photos or Measurements: If possible, take clear photos of the cartridge from different angles or use a measuring tape to record its dimensions. These details can be helpful when seeking a replacement cartridge.

- Consult Manufacturer Documentation: If you have the original documentation or instruction manual for your shower valve, check if it includes information about the cartridge type or model. The manufacturer’s website may also have resources or guides to assist in identifying cartridges based on their features.

- Seek Professional Assistance: If you’re unable to identify the cartridge or require further guidance, consider reaching out to a plumbing professional or contacting the shower valve manufacturer’s customer support. They can provide expert advice and help you find the right replacement cartridge.

A gyár kapacitása és kapacitása:

(1) Összeszerelés

Első osztályú független kutatási és fejlesztési összeszerelési platformmal rendelkezünk. A hidraulikus hengergyártó műhely négy félautomata emelőhenger-összeszerelő sorral és egy automata billenőhenger-összeszerelő sorral rendelkezik, tervezett éves gyártási kapacitása 1 millió darab. A speciális henger műhely különböző specifikációjú félautomata tisztító összeszerelő rendszerrel van felszerelve, amelynek tervezett éves termelési kapacitása 200.000, és híres CNC megmunkáló berendezéssel, megmunkáló központtal, nagy pontosságú hengerfeldolgozó speciális berendezéssel, robothegesztő géppel, automatikus tisztítógéppel, automatikus henger összeszerelő géppel és automatikus festési gyártósorral van felszerelve. A meglévő kritikus berendezések több mint 300 készlet (készlet). A berendezések erőforrásainak optimális elosztása és hatékony felhasználása biztosítja a termékek pontossági követelményeit és megfelel a termékek minőségi igényeinek.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: