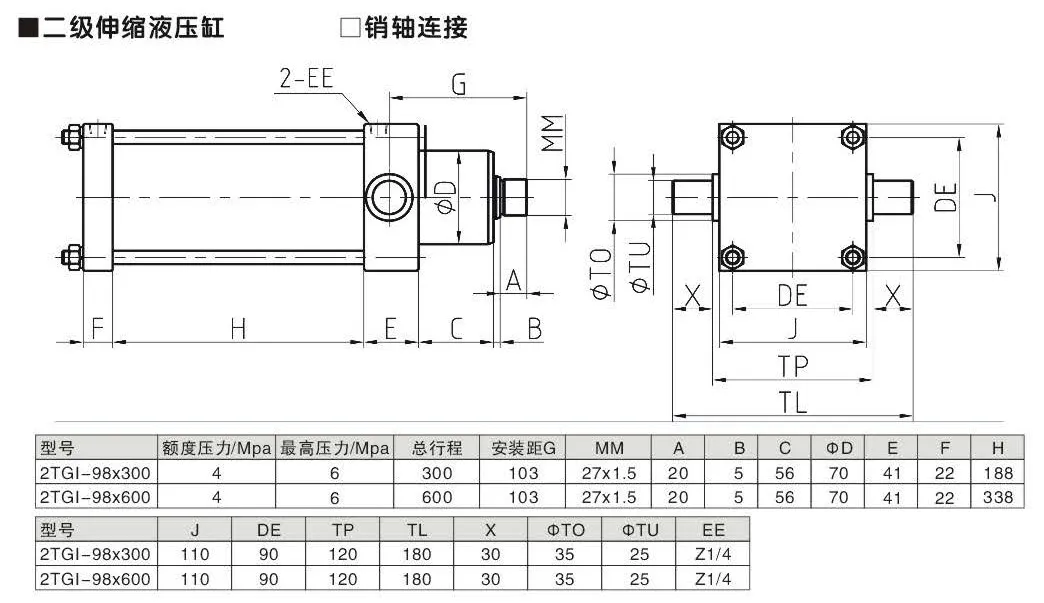

Pin Joint Two Stage Telescopic Hydraulic Cylinder

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

Pin Joint Two Stage Telescopic Hydraulic Cylinder

The pin joint two-stage telescopic hydraulic cylinder is a cutting-edge hydraulic element designed to provide efficient and reliable power transmission for a variety of industrial applications. With its innovative design, superior performance, and versatility, this hydraulic cylinder offers precise control and increased productivity. Whether used in construction, agriculture, or material handling, pin jonint two-stage telescopic hydraulic cylinders are designed to optimize the hydraulic operation and provide superior results.

CX series compact cylinders are used for clamping cylinders. Its installation is small. Our factory has advanced hydraulic equipment, including a vertical and horizontal machining center and medium and large hydraulic cylinders. Thin cylinder production technology is excellent.

Pin Joint Two Stage Telescopic Hydraulic Cylinder Parameter:

Pin Joint Two Stage Telescopic Hydraulic Cylinder Key Features and Benefits:

- Two-Stage Telescopic Design:

- The Pin Joint Two Stage Telescopic Hydraulic Cylinder features a two-stage telescopic design that increases stroke length while maintaining a compact retracted size.

- This design provides flexibility in hydraulic applications where extended reach is required without sacrificing space constraints.

- Pin Joint Construction:

- The cylinder incorporates pin joint construction, which enables smooth and synchronized movement of the telescopic stages.

- The pin joint mechanism ensures operation stability, precision, and excellent load-bearing capacity.

- Precise Control:

- This hydraulic cylinder offers exceptional control over extension and retraction, allowing precise positioning and efficient operations.

- The precise control mechanism ensures smooth and controlled movement, enhancing overall productivity.

- High Load-Bearing Capacity:

- The Pin Joint Two Stage Telescopic Hydraulic Cylinder is engineered to handle heavy loads and demanding industrial applications.

- It provides excellent load-bearing capacity, making it suitable for lifting, pushing, or pulling substantial weights.

Pin Joint Two Stage Telescopic Hydraulic Cylinder Usage Method:

- Mounting and Installation:

- Determine the appropriate installation location for the pin joint secondary telescopic hydraulic cylinder based on the specific requirements of your equipment or machine.

- Ensure that the mounting surface is strong, level, and can safely support the weight and load of the cylinder.

- Hydraulic System Connection:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Align and secure the connections properly to prevent leaks and ensure optimal performance.

- Operating the Cylinder:

- Start the hydraulic system and start the movement of the two-stage telescopic hydraulic cylinder of the pin joint.

- The hydraulic control system is used to precisely control the extension of the cylinder and improve the operating efficiency.

How To Replace Seals In Hydraulic Cylinder?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair’s adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair’s base and connects to the seat or the chair’s mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair’s remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional to obtain the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best compact hydraulic cylinder manufacturers. We can offer comprehensive compact hydraulic cylinder stock. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Aplikasi Silinder Hidraulik: