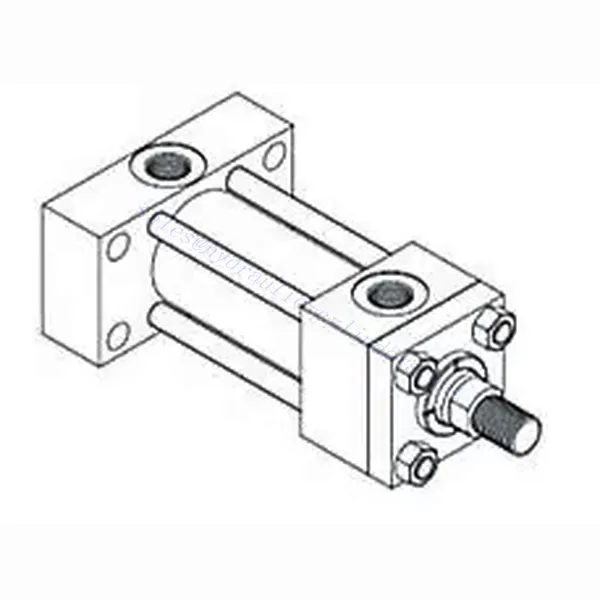

Coperchio posteriore Flangia rettangolare Cilindro idraulico a quattro steli

In qualità di uno dei produttori, fornitori ed esportatori di prodotti meccanici, offriamo cilindri idraulici e molti altri prodotti.

Per maggiori dettagli, contattateci.

Posta:sales@hydraulic-cylinders.net

Produttore fornitore esportatore di cilindri idraulici.

Coperchio posteriore Flangia rettangolare Cilindro idraulico a quattro steli

The rear cover rectangular flange four rod hydraulic cylinder is a versatile and robust four rod hydraulic cylinder designed to provide reliable and efficient linear motion in various industrial applications. With its unique design and exceptional performance, this four rod hydraulic cylinder offers outstanding power and precision, making it an ideal choice for demanding hydraulic systems.

Essential Characteristics Of Four Rod Hydraulic Cylinder:

High Strength Construction:

-

- The four rod hydraulic cylinder has a robust construction and uses high-quality materials to ensure durable and long-lasting performance.

- It can withstand heavy loads and harsh operating conditions and is suitable for demanding industrial applications.

Rectangular Flange Design:

-

- The back cover of this four rod hydraulic cylinder is fitted with a rectangular flange, providing a safe and stable installation option.

- Flanges are designed for easy installation and calibration, ensuring an accurate fit within the hydraulic system.

Four Rod Configuration:

-

- The four rod hydraulic cylinder adopts a four-bar design to improve stability and load-carrying capacity.

- The four rods evenly distribute the load, reducing the stress on each component and ensuring smooth and balanced operation.

Exceptional Performance:

-

- The cylinders offer high performance and provide accurate and reliable linear motion control.

- It provides superior force output and stroke length, allowing efficient operation in a variety of applications.

Rear Cover Rectangular Flange Four Rod Hydraulic Cylinder Parameter:

Coperchio posteriore Flangia rettangolare Cilindro idraulico a quattro steli Usage Method:

Mounting:

-

- Determine the proper position of the hydraulic cylinder in the hydraulic system.

- Ensure the mounting surface is clean and free from any debris or contaminants.

- Place the rectangular flange flush with the mounting face and secure it with appropriate bolts or fasteners.

Hydraulic Connections:

-

- Connect the hydraulic supply line to the cylinder port to ensure proper seal and prevent leakage.

- Follow the manufacturer’s recommendations for the type of hydraulic oil and fill the system accordingly.

Operation:

-

- Start the hydraulic system and use the hydraulic control valve to control the cylinder movement.

- Adjust flow and pressure Settings to achieve the desired speed and force output.

- Monitor four rod hydraulic cylinder operation for any anomalies or signs of failure.

Coperchio posteriore Flangia rettangolare Cilindro idraulico a quattro steli Maintenance:

Regular Inspection:

-

- Perform a routine visual inspection to check for any signs of wear, leakage, or damage.

- Check seals, tie rods, and cylinder blocks for abnormalities and replace worn or damaged parts promptly.

Lubrication:

-

- Follow the manufacturer’s lubrication interval guidelines and use the recommended lubricant to ensure smooth operation.

- Lubricate rods and seals to prevent friction and extend cylinder life.

Seal Replacement:

-

- Over time, the seals may wear out and require replacement.

- When replacing seals, ensure they are of the correct size and type recommended by the manufacturer.

- When replacing the seal, remove and reassemble the cylinder according to the correct procedure.

How To Control Hydraulic Cylinder Speed?

Controlling the speed of a hydraulic cylinder is essential to ensure safe and efficient operation in various applications. Here are some methods to control the speed of a hydraulic cylinder:

- Flow Control Valve:

- The most common method to control a hydraulic cylinder’s speed is using a flow control valve.

- A flow control valve regulates the amount of hydraulic fluid flowing into and out of the cylinder, thereby controlling the speed of the cylinder’s movement.

- Flow control valves are available in various types, including needle valves, adjustable orifice valves, and throttle valves.

- By adjusting the opening of the flow control valve, you can regulate the flow rate of the hydraulic fluid and, consequently, the speed of the cylinder.

- Proportional Control Valves:

- Proportional control valves provide more precise speed control than standard flow control valves.

- These valves allow for continuous flow rate adjustment, providing finer control over the cylinder’s speed.

- Proportional control valves are often used in applications where precise positioning and speed control are critical, such as in robotics or automation systems.

- Pressure Control:

- The speed of a hydraulic cylinder can also be indirectly controlled by adjusting the system’s pressure.

- Increasing the pressure will result in faster cylinder movement while reducing the pressure will slow it down.

- Pressure control can be achieved by using a pressure relief valve or a pressure-compensated flow control valve in the hydraulic system.

- Load Control:

- The load on the hydraulic cylinder can affect its speed of operation.

- Increasing the load will generally slow down the cylinder due to the increased resistance.

- To control the speed under different load conditions, you can incorporate load-sensing valves or load-compensated flow control valves into the hydraulic system.

- These valves adjust the flow rate based on the load, ensuring consistent speed regardless of the load variation.

- Cylinder Size and Design:

- The size and design of the hydraulic cylinder itself can influence its speed characteristics.

- A larger cylinder diameter generally provides higher speed due to the larger piston area, while a smaller diameter cylinder will result in slower speed.

- The cylinder’s design, including the diameter of the ports and the internal passages, can also impact the speed of the cylinder’s movement.

- When selecting a hydraulic cylinder, consider the desired speed requirements and consult the manufacturer’s specifications to choose an appropriate size and design.

Capacità e capacità della fabbrica:

(1) Montaggio

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Lavorazione

L'officina di lavorazione è dotata di un centro di tornitura su rotaia inclinata personalizzato, di un centro di lavorazione, di una levigatrice ad alta velocità, di un robot di saldatura e di altre attrezzature correlate, in grado di gestire la lavorazione di tubi cilindrici con un diametro interno massimo di 400 mm e una lunghezza massima di 6 metri.

(3) Saldatura

(4) Verniciatura e rivestimento

Con linee automatiche di verniciatura a base d'acqua a cilindro di piccole e medie dimensioni, per realizzare il carico e lo scarico automatico con robot e la spruzzatura automatica, la capacità di progettazione è di 4000 pezzi per turno;

Disponiamo anche di una linea di produzione semiautomatica di vernici per cilindri di grandi dimensioni alimentata da una catena di potenza, con una capacità di progettazione di 60 casse per turno.

(5) Test

Disponiamo di strutture di ispezione e banchi di prova di prim'ordine per garantire che le prestazioni del cilindro siano conformi ai requisiti.

We are one of the best light four rod hydraulic cylinder manufacturers. We can offer comprehensive light four rod hydraulic cylinder stock. We also provide corresponding riduttori agricoli. Abbiamo esportato i nostri prodotti in tutto il mondo e ci siamo guadagnati una buona reputazione grazie alla qualità superiore dei nostri prodotti e al servizio post-vendita. Accogliamo calorosamente i clienti sia in patria che all'estero per contattarci per negoziare affari, scambiare informazioni e collaborare con noi!

Visitate la nostra fabbrica VR:

Fate un tour della nostra fabbrica VR con quanto segue

Cilindro idraulico Applicazione: