Aerial Work Platform Steering Cylinder

Являясь одним из производителей, поставщиков и экспортеров механической продукции, мы предлагаем гидравлические цилиндры и многие другие изделия.

Пожалуйста, свяжитесь с нами для получения подробной информации.

Почта:sales@hydraulic-cylinders.net

Производитель поставщик экспортер гидроцилиндров.

Aerial Work Platform Steering Cylinder

The aerial work platform steering cylinder is a critical component designed to enhance maneuverability and control in aerial work platforms. This specialized hydraulic cylinder is vital in steering the platform, allowing operators to navigate safely and efficiently at elevated heights.

The aerial work platform steering is indispensable for enhancing maneuverability, control, and operator comfort in elevated work environments. With its robust construction, precise steering control, improved maneuverability, and operator-centric design, this hydraulic cylinder facilitates smooth navigation and efficient access in various elevated work applications. By following the recommended usage methods and maintenance practices, operators can maximize the longevity and performance of the aerial work platform steering, contributing to increased productivity, safety, and confidence in elevated work scenarios. Invest in this essential hydraulic component to elevate your aerial work platform’s maneuverability, control, and efficiency, unlocking new productivity levels and success in elevated work operations.

Aerial Work Platform Steering Cylinder Key Characteristics:

- Надежная конструкция:

- The Aerial Work Platform Steering Cylinder is constructed using high-quality materials, ensuring durability and reliability.

- It is engineered to withstand the demands of challenging work environments and withstand heavy loads.

- Precise Steering Control:

- This cylinder facilitates precise steering control, enabling operators to maneuver the aerial work platform with accuracy and confidence.

- It ensures smooth and responsive steering, allowing for precise positioning and navigation in tight spaces or complex worksites.

- Enhanced Maneuverability:

- The Aerial Work Platform Steering Cylinder enhances the overall maneuverability of the platform, allowing operators to navigate efficiently and access hard-to-reach areas.

- It enables smooth turns and precise adjustments, contributing to increased productivity and versatility in elevated work applications.

- Operator Comfort:

- The steering cylinder is designed to provide ergonomic control, reducing operator fatigue and enhancing comfort during extended work periods.

- It offers smooth and effortless steering, minimizing operator effort and ensuring a comfortable working experience.

Aerial Work Platform Steering Cylinder Parameter:

| Product Name | Aerial Work Platform Steering Cylinder |

| Features: | Steering system for chassis tires of aerial work vehicles |

| Bore diameter: | 63mm~200mm |

| Rod diameter: | 36mm~140mm Stroke≤1000mm |

| Pressure: | 30MPa(Maximum pressure) |

| Hydraulic Steering Cylinder Applications: | Aerial Work Platform |

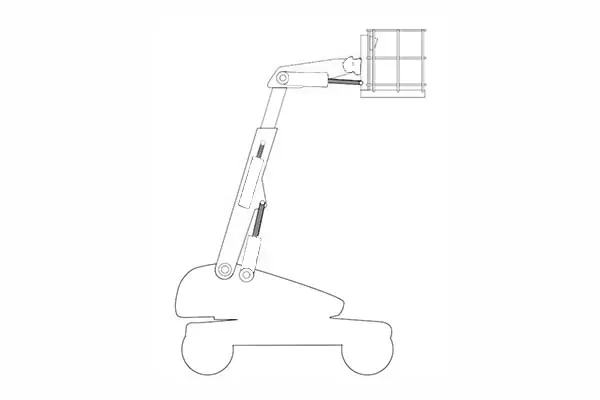

Aerial Work Platform Identification Diagram:

Usage Method Of Aerial Work Platform Steering Cylinder:

- Installation and Setup:

- Follow the manufacturer’s instructions for proper installation and setup of the aerial work platform steering.

- Ensure that the cylinder is securely mounted and aligned to ensure optimal performance.

- Hydraulic Connection:

- Connect the steering cylinder to the hydraulic system of the aerial work platform according to the provided guidelines.

- Ensure all hydraulic connections are secure and properly sealed to prevent leaks or loss of hydraulic fluid.

- Steering Operation:

- Engage the control mechanisms or steering wheel on the aerial work platform to control the steering cylinder.

- Follow the recommended procedures and safety guidelines during the steering operation.

- Responsiveness and Precision:

- Familiarize yourself with the steering response and sensitivity of the platform equipped with the steering cylinder.

- Practice gradual and controlled steering inputs to achieve precise positioning and smooth maneuvering.

How To Flush Hydraulic System?

Flushing a hydraulic system is a crucial maintenance procedure that helps remove contaminants, old fluid, and debris from the system, ensuring optimal performance and longevity. Here’s a step-by-step guide on how to flush a hydraulic system:

- Gather the Required Tools and Supplies:

- Safety goggles and gloves

- Drain pan or bucket

- Clean rags or towels

- Wrench or pliers

- Hydraulic system flushing fluid (recommended by the manufacturer)

- Replacement hydraulic fluid (if needed)

- Prepare the Work Area:

- Park the equipment on a level surface and engage any safety mechanisms, such as setting the parking brake or blocking the wheels.

- Ensure there is sufficient ventilation in the area to avoid inhaling fumes from the flushing fluid.

- Identify the System Components:

- Familiarize yourself with the hydraulic system components, including the reservoir, filters, hoses, and fittings.

- Refer to the equipment’s manual or consult the manufacturer’s guidelines for specific instructions on locating these components.

- Drain the Existing Fluid:

- Place the drain pan or bucket beneath the hydraulic reservoir.

- Use a wrench or pliers to loosen the drain plug or remove the drain cap, allowing the old fluid to drain completely.

- Dispose of the old fluid in accordance with local regulations.

- Remove and Clean Filters:

- Locate the hydraulic filters and remove them according to the manufacturer’s instructions.

- Inspect the filters for signs of dirt, debris, or damage.

- Clean or replace the filters as necessary before reinstalling them.

- Connect Flushing Equipment:

- Attach a flushing line or hose to the hydraulic system, ensuring a secure connection.

- Position the other end of the flushing line into the container of flushing fluid.

- Flush the System:

- Slowly introduce the flushing fluid into the hydraulic system by turning on the equipment or activating the hydraulic pump.

- Allow the flushing fluid to circulate through the system for a specified duration as recommended by the manufacturer.

- Operate any hydraulic controls to ensure the flushing fluid reaches all components.

- Drain the Flushing Fluid:

- Disconnect the flushing line from the hydraulic system.

- Reinstall the drain plug or cap on the reservoir.

- Allow the flushing fluid to drain completely into the drain pan or bucket.

- Refill with New Hydraulic Fluid:

- Ensure the reservoir is clean and free of any residual flushing fluid.

- Refer to the equipment’s manual or manufacturer’s guidelines for the appropriate type and quantity of hydraulic fluid.

- Slowly pour or pump the new hydraulic fluid into the reservoir, avoiding overfilling.

- Bleed and Test the System:

- Follow the manufacturer’s instructions for bleeding air from the system, if required.

- Start the equipment or activate the hydraulic pump, and operate the controls to ensure proper functioning of the system.

- Check for any leaks or abnormalities during operation.

Возможности и мощности завода:

(1) Сборка

Мы располагаем первоклассной независимой сборочной платформой для проведения исследований и разработок. Цех по производству гидравлических цилиндров имеет четыре полуавтоматические линии сборки подъемных цилиндров и одну автоматическую линию сборки цилиндров наклона с проектной годовой производственной мощностью 1 млн. штук. Цех по производству специальных цилиндров оснащен полуавтоматической очистной сборочной системой различных спецификаций с проектной годовой производственной мощностью 200 тыс. штук и оснащен известным обрабатывающим оборудованием с ЧПУ, обрабатывающим центром, высокоточным специальным оборудованием для обработки цилиндров, роботом-сварщиком, автоматической очистной машиной, автоматической сборочной машиной цилиндров и автоматической покрасочной производственной линией. Существующее критически важное оборудование насчитывает более 300 комплектов (комплектов). Оптимальное распределение и эффективное использование ресурсов оборудования позволяет обеспечить требования к точности изделий и удовлетворить потребности в высоком качестве продукции.

(2) Механическая обработка

Цех оснащен специализированным токарным центром с наклонной направляющей, обрабатывающим центром, высокоскоростным хонинговальным станком, сварочным роботом и другим сопутствующим оборудованием, которое позволяет обрабатывать цилиндрические трубы с максимальным внутренним диаметром 400 мм и максимальной длиной 6 м.

(3) Сварка

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: