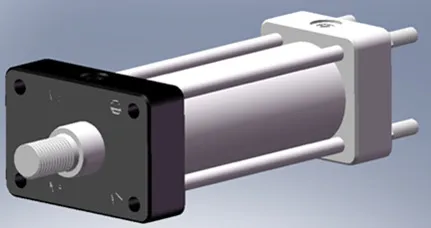

低压液压缸前法兰

低压液压缸前法兰

Looking for a reliable and durable solution for your low-pressure hydraulic systems? Our 低压液压缸前法兰 is designed to deliver exceptional performance and longevity, making it the perfect choice for a wide range of applications. Engineered for low-pressure hydraulic systems, this front flange ensures reliable operation even in demanding environments. With its durable construction, it is built to withstand harsh conditions, providing long-lasting performance and reducing the need for frequent replacements. Whether you need an affordable front flange for hydraulic systems or a durable front flange for low-pressure applications, our product is easy to install and maintain, significantly reducing downtime and improving operational efficiency. Upgrade your hydraulic systems today with our 低压液压缸前法兰 and experience unmatched reliability and performance!

Looking for a reliable and durable solution for your low-pressure hydraulic systems? Our 低压液压缸前法兰 is designed to deliver exceptional performance and longevity, making it the perfect choice for a wide range of applications. Engineered for low-pressure hydraulic systems, this front flange ensures reliable operation even in demanding environments. With its durable construction, it is built to withstand harsh conditions, providing long-lasting performance and reducing the need for frequent replacements. Whether you need an affordable front flange for hydraulic systems or a durable front flange for low-pressure applications, our product is easy to install and maintain, significantly reducing downtime and improving operational efficiency. Upgrade your hydraulic systems today with our 低压液压缸前法兰 and experience unmatched reliability and performance!

Low-pressure Hydraulic Cylinder Front Flange Technical Specifications:

Key Features of Our Hydraulic Cylinder Front Flange:

Our 低压液压缸前法兰 is engineered to deliver exceptional performance and durability for your hydraulic systems. Here’s what makes it stand out:

- Reliable Performance: Designed specifically for low-pressure hydraulic systems, this front flange ensures smooth and efficient operation, even in demanding conditions.

- Durable Construction: Built with high-quality materials, our Hydraulic Cylinder Front Flange for Low-pressure Systems is resistant to wear and tear, making it ideal for use in harsh environments.

- Easy Installation & Maintenance: The user-friendly design of our Front Flange for Hydraulic Cylinders allows for quick installation and hassle-free maintenance, minimizing downtime and maximizing productivity.

- Cost-Effective Solution: As one of the best low-pressure hydraulic cylinder front flanges on the market, our product offers a perfect balance of quality and affordability.

- Versatile Applications: Whether you need an affordable front flange for hydraulic systems or a durable front flange for low-pressure applications, this component is suitable for a wide range of industrial and marine uses.

Upgrade your hydraulic systems with our 低压液压缸前法兰 and experience unmatched reliability, durability, and ease of use!

低压液压缸前法兰的应用:

- 带前法兰的低压液压缸适用于液压压力较低的各种行业和系统。

- 它们通常用于工业机械、移动设备和其他存在空间限制或特定安装要求的系统。

- 这些气缸适用于材料处理、提升机构、输送系统和其他需要线性力或运动的设备。

如何控制液压缸速度?

控制液压缸的速度可通过多种方法实现。以下是几种常见的方法:

- 流量控制阀:流量控制阀专门用于调节进入或流出液压缸的液压油流量。这些阀可以是可调式的,也可以是固定式的,通常安装在与油缸相连的液压管路中。通过调节阀的开度或限制,可以控制允许通过的油量,从而调节油缸的运动速度。

- 节流阀:节流阀又称速度控制阀,专门用于控制液压执行器的速度。它们通常安装在液压缸附近的液压管路中。节流阀限制液压油的流量,产生压降并控制油缸的运动速度。

- 变量泵或马达:在液压系统中使用可变排量泵或马达可以控制流量,从而控制油缸的速度。通过调节泵或马达的排量,可以控制向油缸供应的液压油量,从而影响油缸的速度。

- 比例阀:比例阀可精确控制液压缸的流量和速度。这些阀使用电子或电信号来调节阀的开度,从而实现对液压缸速度的精确和比例控制。

- 蓄电池:液压蓄能器可储存加压液压油,在需求量大时释放出来补充流量。通过在系统中安装蓄能器,可以加强液压缸的速度控制,尤其是在加速或减速阶段。

工厂的能力和产能:

(1) 装配

拥有一流的自主研发装配平台。叉车油缸生产车间拥有四条半自动举升油缸装配线和一条全自动倾斜油缸装配线,设计年生产能力100万件;特种油缸车间配备各种规格的半自动清洗装配系统,设计年生产能力20万只。配备知名数控加工设备、加工中心、高精度气缸加工专用设备、机器人焊接机、自动清洗机、气缸自动装配机、自动喷漆生产线。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量要求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

With small and medium-sized cylinder automatic water-based paint coating line, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift; We also have a semi-automatic paint production line for large cylinders, powered by a power chain, with a design capacity of 60 cases per shift.

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。  我们是最好的低压液压缸制造商之一。我们可以提供广泛的低压液压缸库存。我们还提供相应的 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

我们是最好的低压液压缸制造商之一。我们可以提供广泛的低压液压缸库存。我们还提供相应的 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: