CA Monoaural Type Y Connector Light Rod Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of hydraulic cylinders.

CA Monoaural Type Y Connector Light Rod Hydraulic Cylinder

The CA monoaural type light rod hydraulic cylinder is a specific type with a monoaural design and a light rod construction. Here’s some information about this type of cylinder:

Monophonic Design: The monophonic design means the hydraulic cylinder protrudes a single rod from one end. This design is often used in applications requiring limited space or a more compact cylinder.

Light Rod Structure: Light rod structure refers to using lightweight materials, such as aluminum or composite materials, as the rod of the hydraulic cylinder. This structure helps reduce the cylinder’s weight while maintaining strength and performance.

Compact Size: CA monophonic light rod hydraulic cylinders are known for their compact size and are suitable for limited space applications. Its small footprint makes it easy to install and integrate into various systems.

Precise Linear Motion Control: This type of hydraulic cylinder is designed to provide exact linear motion control. The light pole construction and monophonic design contribute to smooth and accurate movement, allowing for precise positioning and control in industrial applications.

Versatile: CA monaural type light rod hydraulic cylinders can be used in various industrial applications. It has practical value in robotics, packaging machinery, automation systems, and other applications that require efficient and precise linear motion control.

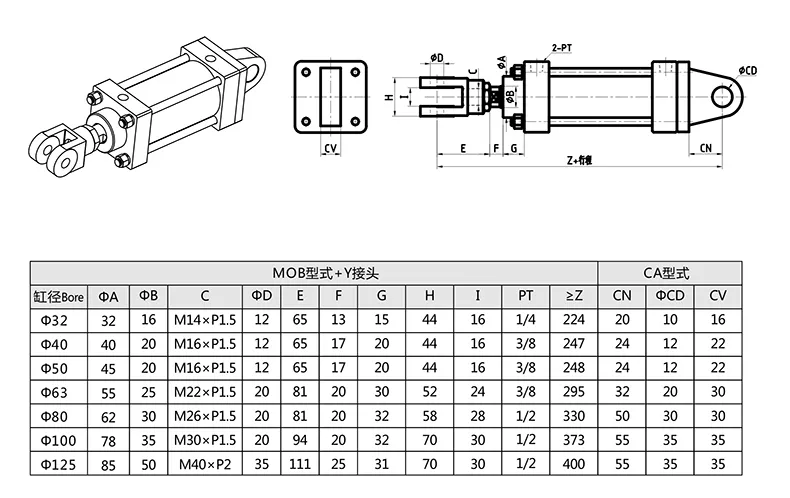

CA Monoaural Type Y Connector Light Rod Hydraulic Cylinder Parameter:

CA Monoaural Type Y Connector Light Rod Hydraulic Cylinder Maintenance:

Proper care is essential to maximize the life and performance of the CA monoaural type light rod hydraulic cylinder.

Here are some maintenance guidelines:

Regular inspection: Check the light rod hydraulic cylinder for wear, damage, or leakage. Pay attention to seals, fittings, and mounting points.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder according to the manufacturer’s guidelines. Regular lubrication ensures smooth operation and minimizes friction-related problems.

Replace seals: If seals are deteriorating or leaking, replace seals with authentic parts approved by the manufacturer.

Cleaning: Keep the light rod hydraulic cylinder clean and remove dirt, debris, and contaminants that may affect the cylinder’s performance. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid.

How To Bleed A Hydraulic Cylinder Without Bleeder Valve?

Bleeding a hydraulic cylinder without a bleeder valve can be more challenging, but it is still possible. Here’s a step-by-step guide on how to bleed a hydraulic cylinder without a bleeder valve:

- Prepare the Necessary Tools: Before starting the bleeding process, gather the following tools: a wrench or socket set, a container to catch hydraulic fluid, and a clean cloth or rag.

- Position the Cylinder: Ensure that the hydraulic cylinder is safe and stable. Use clamps or fixtures to secure it and prevent accidental movement during bleeding if necessary.

- Locate the Highest Point: Identify the highest point on the hydraulic cylinder. This is the point where air tends to accumulate. It is usually near the cylinder’s end or the piston rod’s top.

- Loosen the Fittings: Using a wrench or socket set, carefully loosen the fitting or connection at the highest point of the cylinder. Ensure that the fitting is only loosened enough to allow air to escape and not to cause hydraulic fluid leakage.

- Slowly Extend the Cylinder: Activate the hydraulic system to extend the cylinder slowly. This action helps push the air bubbles towards the open fitting and allows them to escape.

- Monitor Fluid Flow: Pay close attention to the hydraulic fluid flow as the cylinder extends. Look for any air bubbles or foam in the fluid. Allow the liquid to flow until you observe a consistent and smooth flow without air bubbles.

- Tighten the Fitting: When confident that all the air has been bled from the cylinder, carefully tighten the fitting or connection at the highest point. Make sure it is adequately secured to prevent any hydraulic fluid leakage.

- Repeat the Process: If multiple cylinders exist in the hydraulic system or other high points where air might have collected, repeat steps 4 to 7 for each cylinder or high end.

- Check for Proper Operation: After bleeding the cylinder, test its operation to ensure it functions correctly. Activate the hydraulic system and observe the cylinder’s movement for irregularities or air-related issues. If any problems persist, consider contacting a hydraulic system professional for further assistance.

Capability & Capacity Of Factory:

(1) Assembly

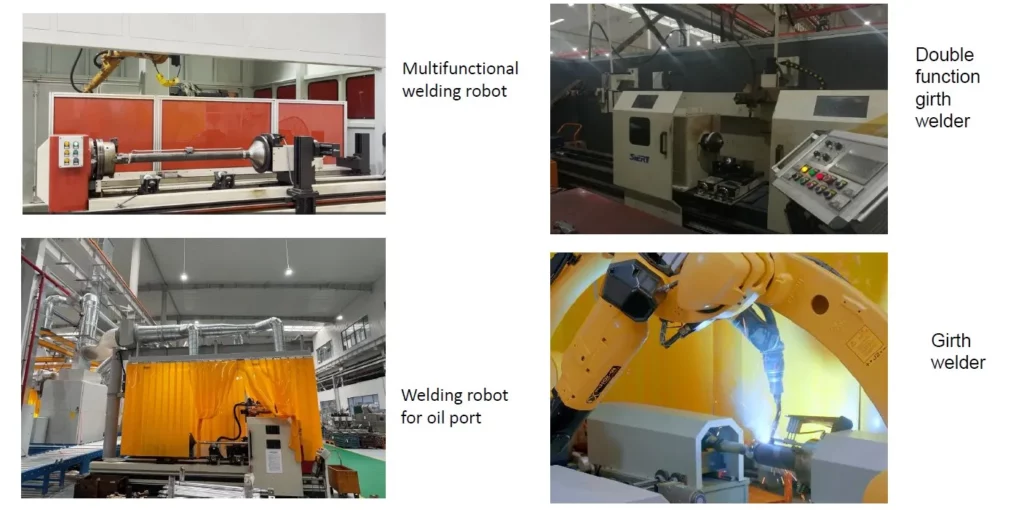

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best light rod hydraulic cylinder manufacturers. We can offer wide light rod hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: